Rail fastening system and insulation method thereof

A technology for steel rails and fasteners, which is applied in the field of railway track component manufacturing, can solve the problems of the under-rail backing plate not contributing to the insulation of the fastener, the under-plate backing plate failing to insulate, and the insulating paint failing to insulate. , to achieve the effect of improving reliability and safety, reducing stray current, high safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

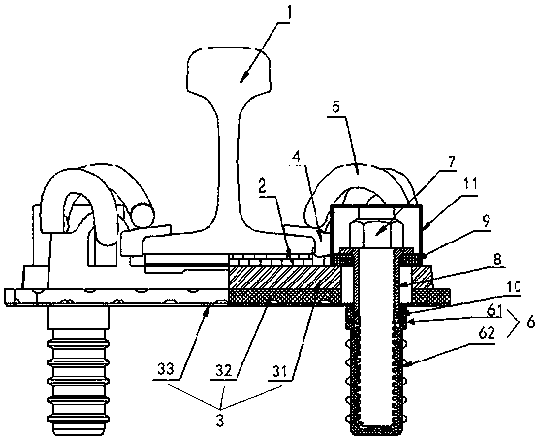

[0031] Combine below Figure 1 to Figure 2 The embodiments of the present invention will be described in detail.

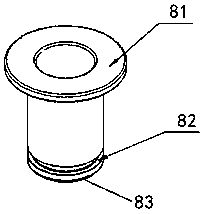

[0032] The rail fastener system includes an under-rail pad 2 under the rail 1, an insulating elastic pad 3 under the under-rail pad 2, and an insulating gauge block 4 pressed on the rail 1, for pressing and insulating The elastic strip 5 of the gauge block 4, the sleeve 6 embedded in the sleeper and the spike 7 fastened in the sleeve 6 through the insulating elastic backing plate 3 are characterized in that the screw of the spike 7 is An insulating sleeve 8 is sheathed in the half section. The lower end of the insulating sleeve 8 extends into the sleeve 6 and is in a sealing fit with the sleeve 6, and the upper end is clamped between the spike 7 and the insulating elastic backing plate 3.

[0033] Such as figure 1 As shown, the upper end of the insulating sleeve 8 separates the spike 7 from the insulating elastic backing plate 3 to prevent the spikes 7 from being conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com