Oil extraction wellhead non-well-killing well shut-in device

A technology for sealing and killing wells, which is applied in wellbore/well components, earthwork drilling, sealing/isolation, etc. It can solve the problems of long time for large equipment to be in place, sudden drop of donkey head and sucker rod, and timely handling of accidents Poor performance and other problems, to achieve the effects of short emergency response time, elimination of safety hazards, and less time-consuming installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

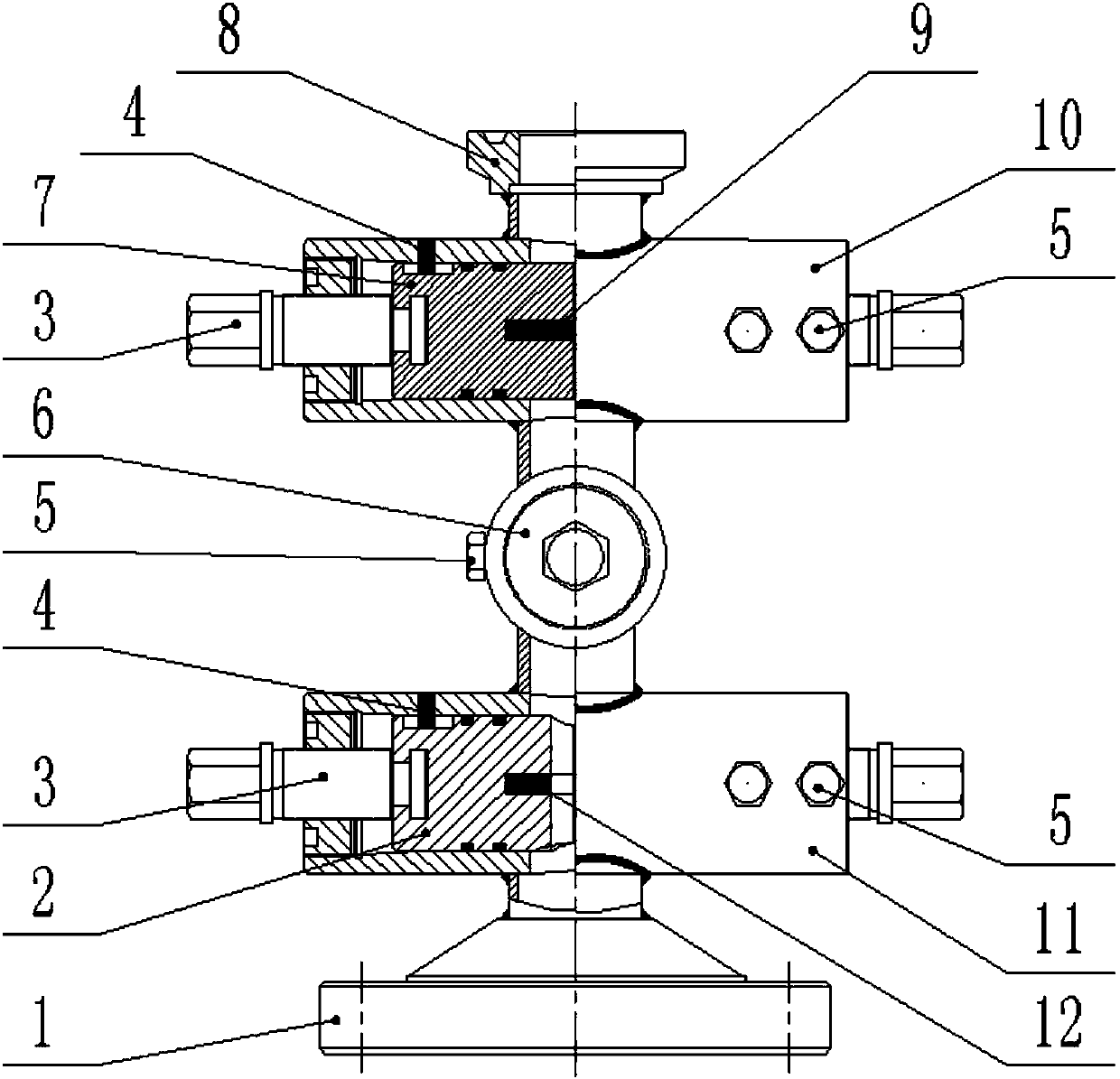

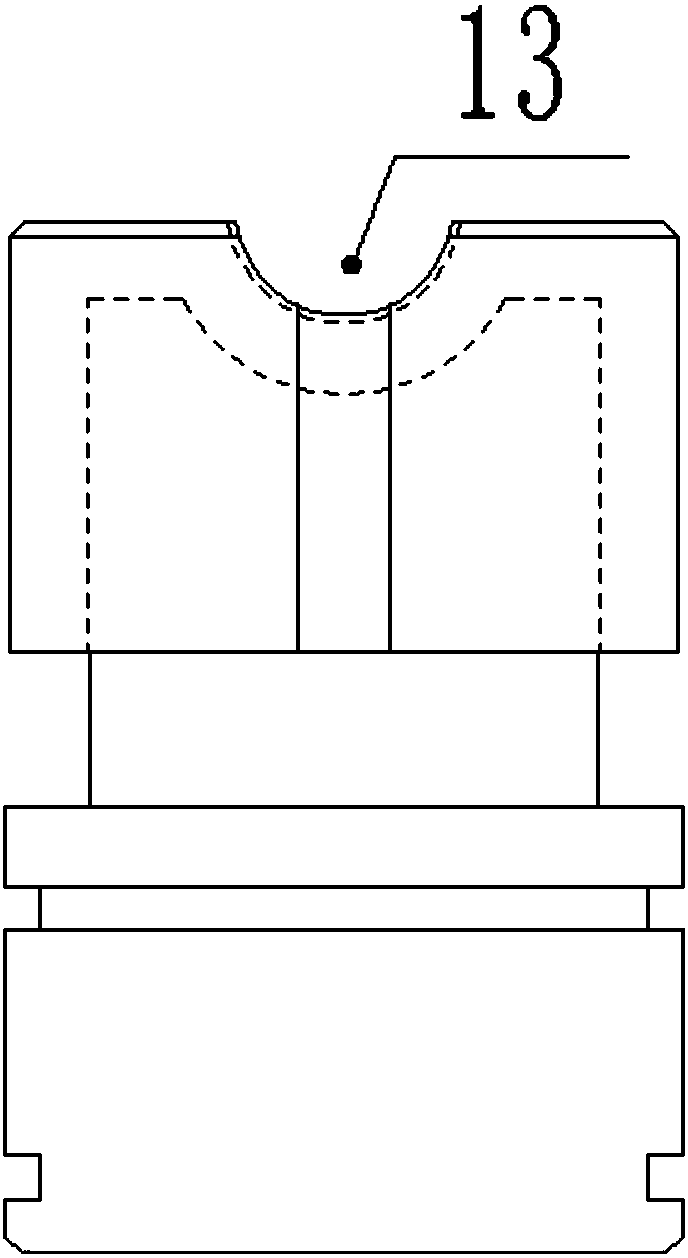

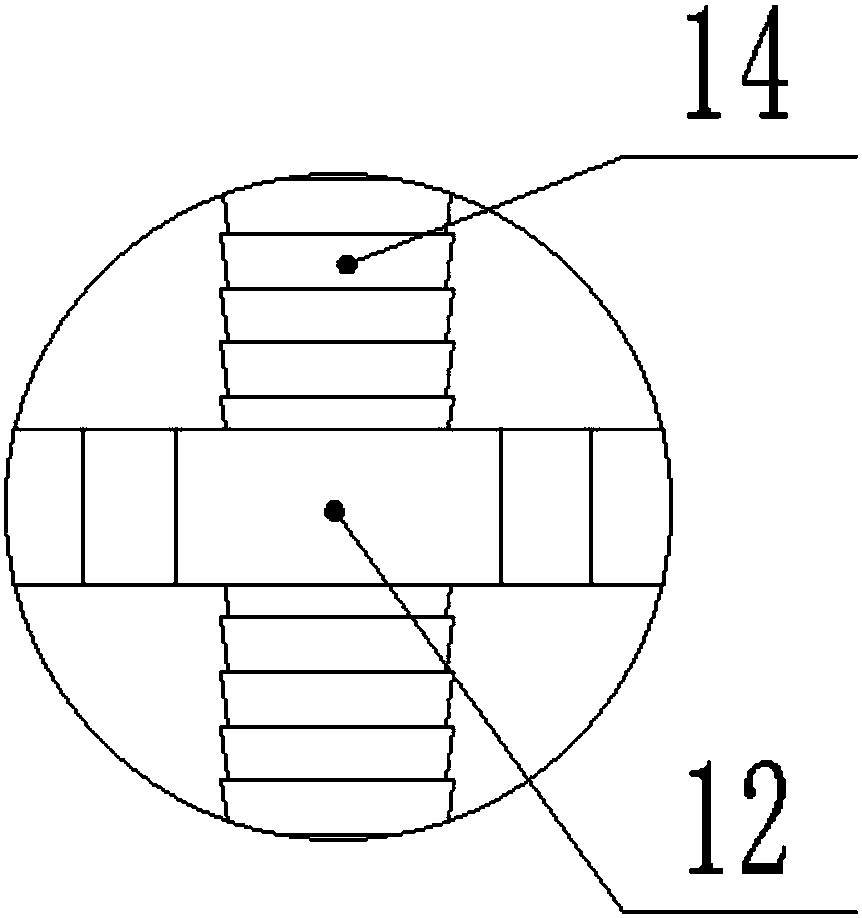

[0020] The present invention will be further described below in conjunction with accompanying drawing:

[0021] The snubbing and sealing device at the production wellhead includes the sealing device 10, the clamping sealer A11 and the clamping sealer B6, and the sealing device 10, the clamping sealer A11 and the clamping sealer B6 pass through the circle from top to bottom The tubes are welded together. After the sealing device 10 is integrated with two sets of clamping sealers, the two purposes of sealing the well and sealing and clamping the oil pumping rod can be achieved with only one installation, and the installation is very convenient; 1. The present invention can be installed on the wellhead flange, the installation process is extremely simple, and the installation time is very little.

[0022] The upper side of the capping device 10 is connected with a clamp joint 8, and the packing box is installed above the well capping device through the clamp joint 8, so that the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com