Efficient gas turbine intake air temperature adjustment system

A technology of gas turbine and intake air temperature, which is applied to the gas turbine device, the air inlet of the turbine/propulsion device, combustion air/combustion-air treatment, etc. It can solve the problems of large heating consumption, large loss of cold and heat neutralization, etc. Achieve the effect of preventing air corrosion and ensuring operating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

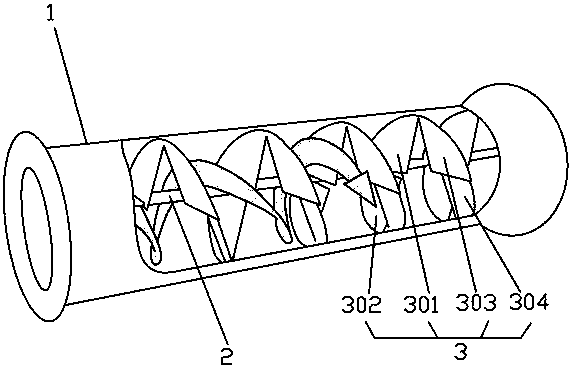

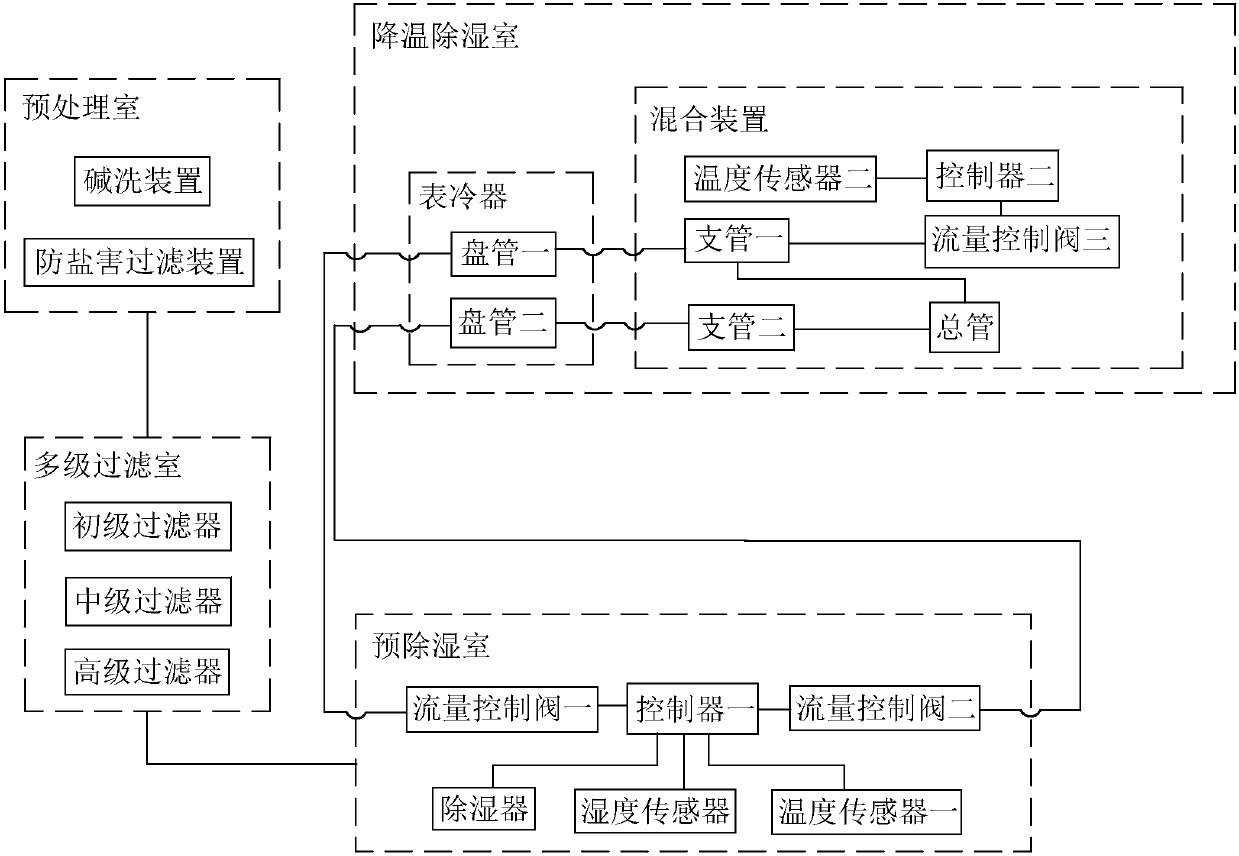

[0028] This embodiment provides a high-efficiency gas turbine air intake temperature adjustment system, the structure of which is as follows: Figure 1-2 shown.

[0029] The system includes a hollow cooling and dehumidifying main body, and the cooling and dehumidifying main body includes an air inlet and an air outlet. The interior of the cooling and dehumidifying main body is sequentially provided with a pretreatment chamber, a multi-stage filter chamber, a pre-dehumidification chamber and a cooling and dehumidification chamber from the air inlet to the air outlet.

[0030] An air corrosion removal device is installed in the pretreatment chamber. The air corrosion removal device includes an alkali washing device and a salt damage prevention filter device arranged in sequence. The salt damage prevention filter device includes an overlapping coarse filter and a dense filter, both of which are made of hydrophobic ultrafine glass fiber become.

[0031] The multi-stage filter c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com