Rotary-cylinder type drying device for drying materials

A drying device and drum technology, applied in the direction of drying solid materials, drying, dryers, etc., can solve the problems of labor consumption, labor, pollution of the environment, etc., to reduce labor intensity, improve drying efficiency, and reduce the cost of hot air low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

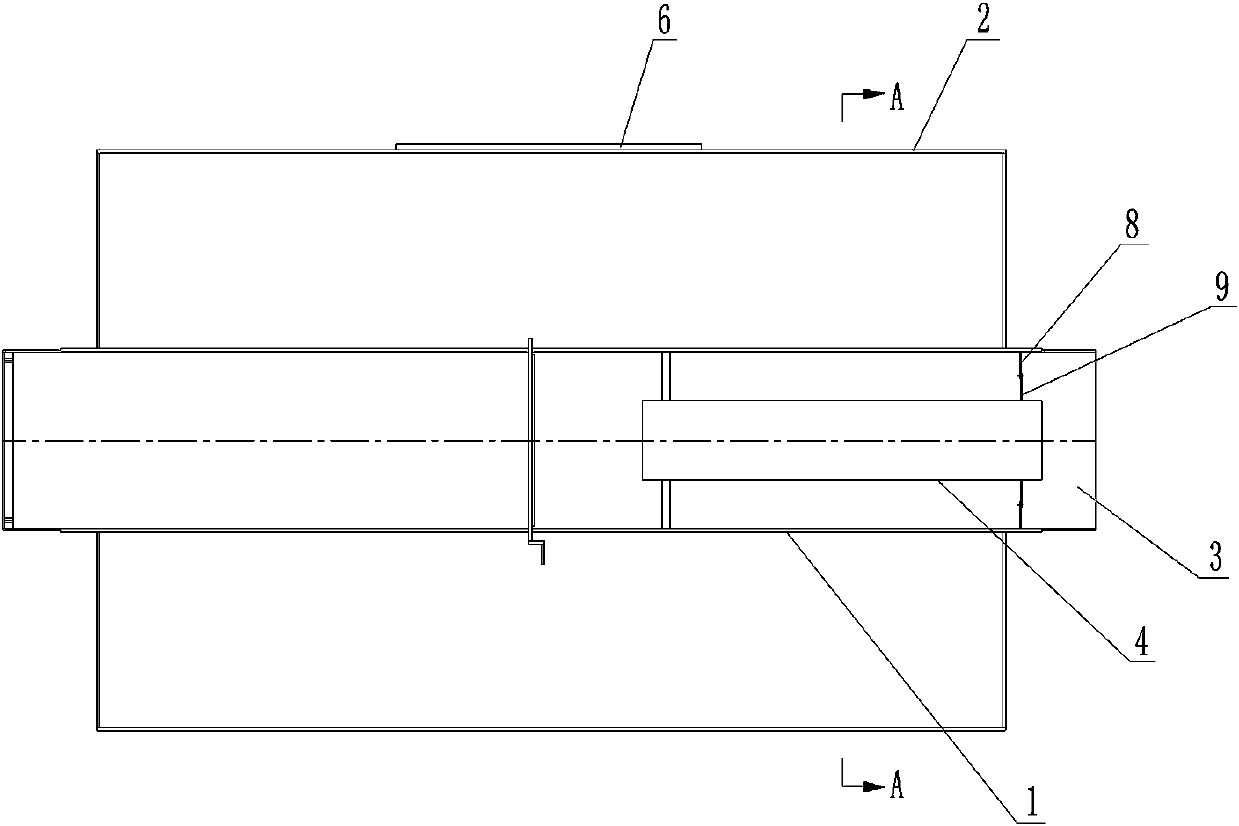

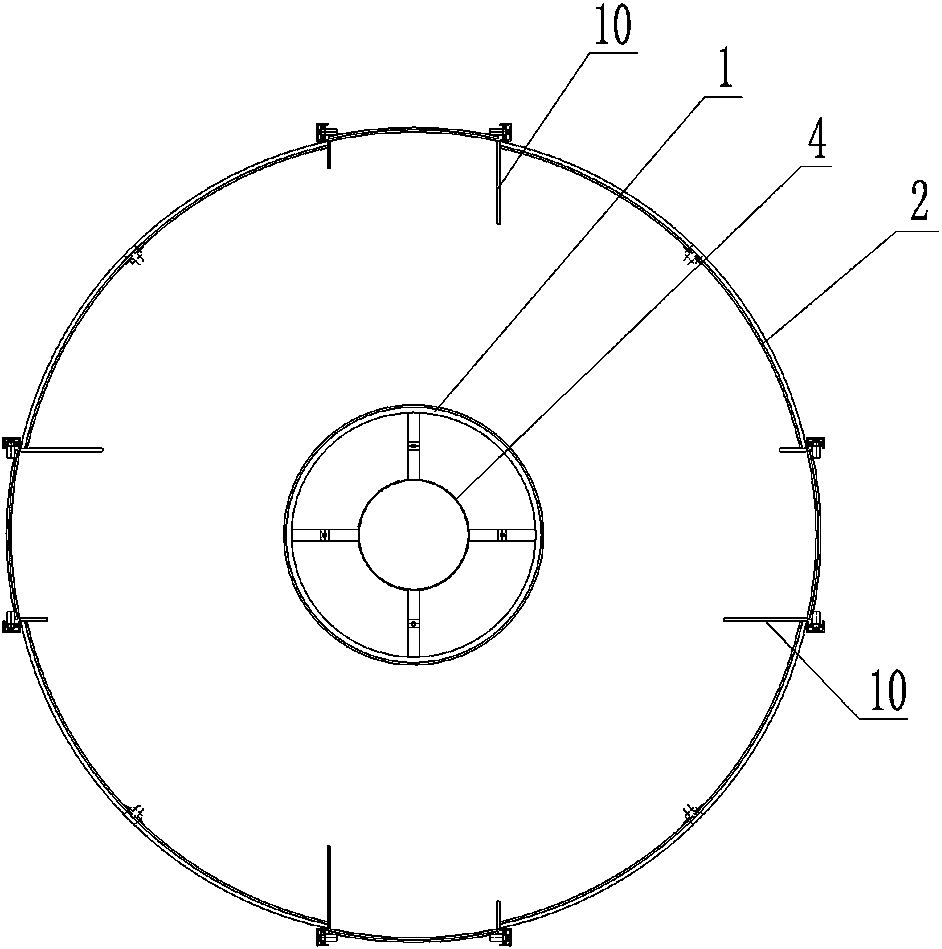

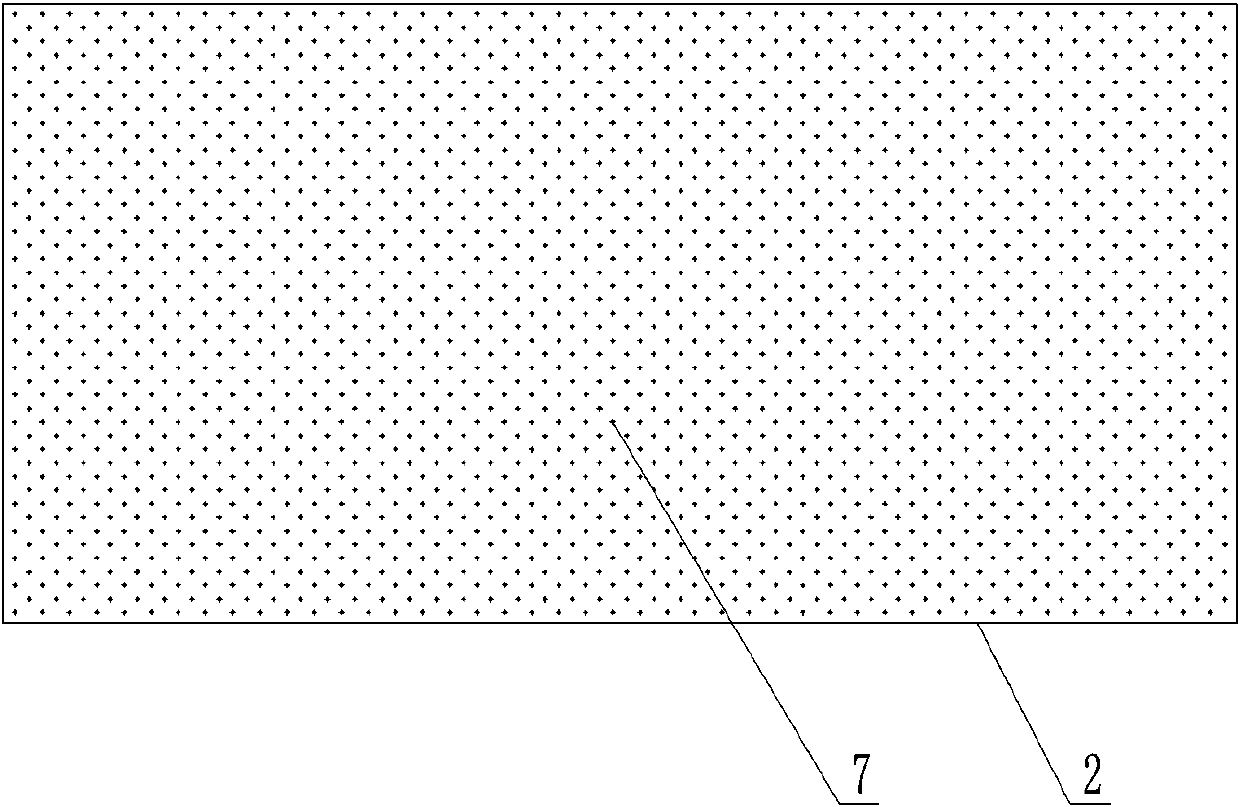

[0022] Embodiment one: if Figure 1~4 As shown, a rotary drum drying device for drying materials, which includes an inner cylinder 1 and an outer cylinder 2, the inner cylinder 1 penetrates the left and right side plates of the outer cylinder 2 along the axial direction of the outer cylinder 2 Setting, the inner cylinder 1 and the outer cylinder 2 are fixedly connected as one, the left and right ends of the inner cylinder 1 extend outside the outer cylinder 2, the left end of the inner cylinder 1 is closed, and the right end of the inner cylinder 1 An air inlet 3 is provided, and a heat blower is connected to the air inlet 3. An air supply pipe 4 arranged along the axial direction of the cylinder is arranged in the inner cylinder 1 and on the left side of the air inlet 3. There are several a vent hole 5; the outer wall of the outer cylinder 2 is provided with a door 6, and several drainage holes 7 are distributed on the cylindrical surface of the outer cylinder 2.

[0023] li...

Embodiment 2

[0031] Embodiment two: if Figure 5~7 As shown, the difference between this embodiment and the first embodiment is that an inner partition 11 is fixed between the inner wall of the outer cylinder 2 and the outer wall of the inner cylinder 1 . Between the inner partition 11 and the left side plate of the outer cylinder 2, and between the inner partition 11 and the right side of the outer cylinder 2, there are a plurality of diameters distributed radially around the outer wall of the inner cylinder 1. To the partition 12, the area between two adjacent radial partitions 12 and the inner partition 11, the side plate of the outer cylinder 2, and the inner wall of the outer cylinder 2 form a drying chamber. Each chamber is correspondingly provided with a warehouse door 6 .

[0032] The device is divided into eight drying chambers. When eight farmers have a small amount of different types of crops, the eight doors are opened first, and the agricultural products of different farmers ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com