Liquid cooling method and device

A cooling device and fluid technology, applied in water shower coolers, lighting and heating equipment, heat exchanger types, etc., can solve problems such as insufficient cooling capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

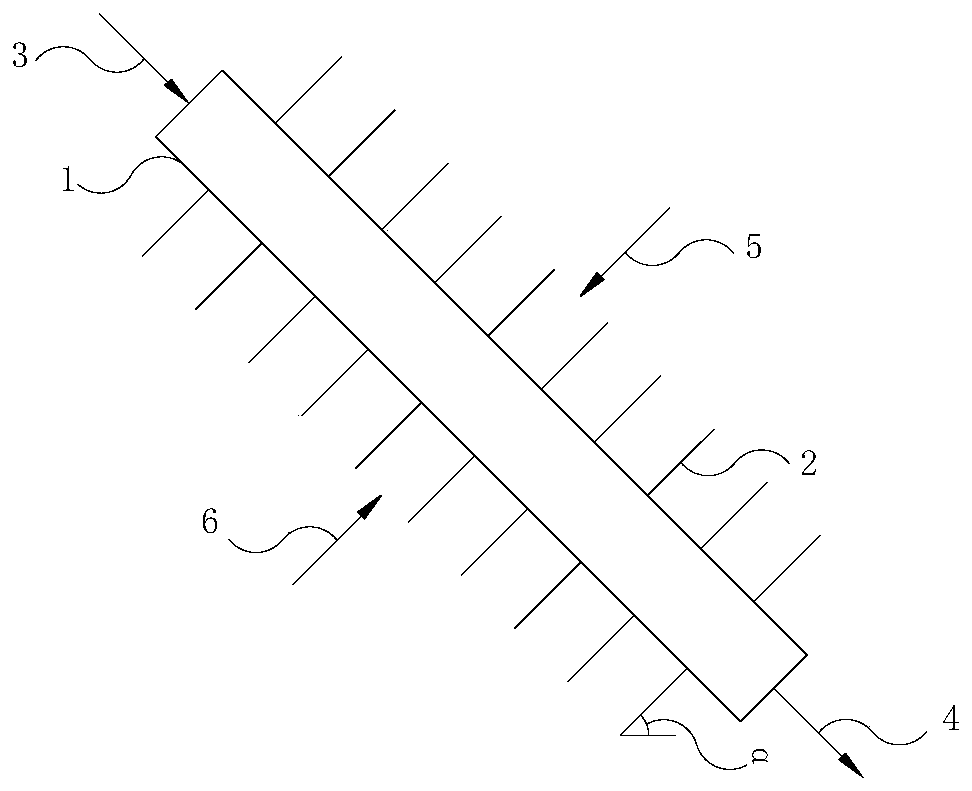

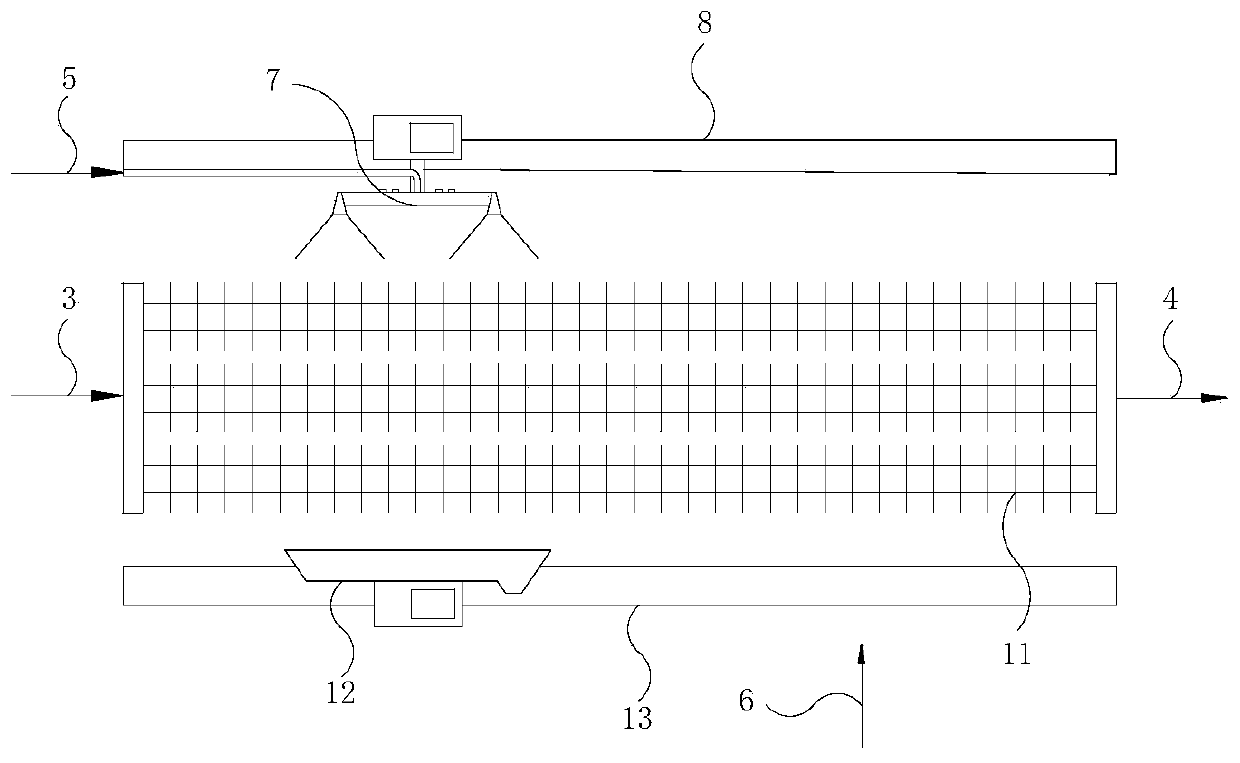

[0038] This embodiment is a cooling scheme for circulating cooling water in the metallurgical industry, such as Figure 4 shown. The cooling system is composed of finned tubes 16 at the upstream section of the fluid tube and finned tubes 17 at the downstream section of the fluid tube connected in series. The hot fluid 3 of the circulating cooling water enters the finned tube 16 in the upstream section of the fluid tube, is cooled by the circulating air 6, and then passes through the upstream and downstream fluid pipeline connection tube 15 and enters the finned tube 17 in the downstream section of the fluid tube, and is further absorbed by the air and water film water. After evaporative cooling and cooling, the finned tubes flow out, and the cold fluid 24 that does not pass through the cold water storage tank is sent to the user as the cold fluid 24 of circulating cooling water. The angle between the fins and the horizontal plane is 45°. The upper surface of the fins is coate...

Embodiment 2

[0042] This embodiment is a cooling scheme for circulating cooling water in the metallurgical industry, such as Figure 5 shown. The cooling system is composed of a finned tube 16 at the upstream section of the fluid tube and a heat exchange metal tube 25 at the downstream section of the fluid tube connected in series. Circulating cooling water enters the finned tube 16 in the upstream section of the fluid tube, is cooled by the circulating air 6, and then enters the heat exchange metal tube 25 in the downstream section of the fluid tube, and is further cooled by the air and water film water, and then flows out of the heat exchange metal tube to the user . The angle between the fins in the upstream section of the fluid tube and the horizontal plane is 75°, the upper and lower surfaces of the fins on the finned tubes are coated with a hydrophilic paint layer, the outer surface of the heat exchange metal tube is coated with a hydrophilic paint layer, and the fins in the upstrea...

Embodiment 3

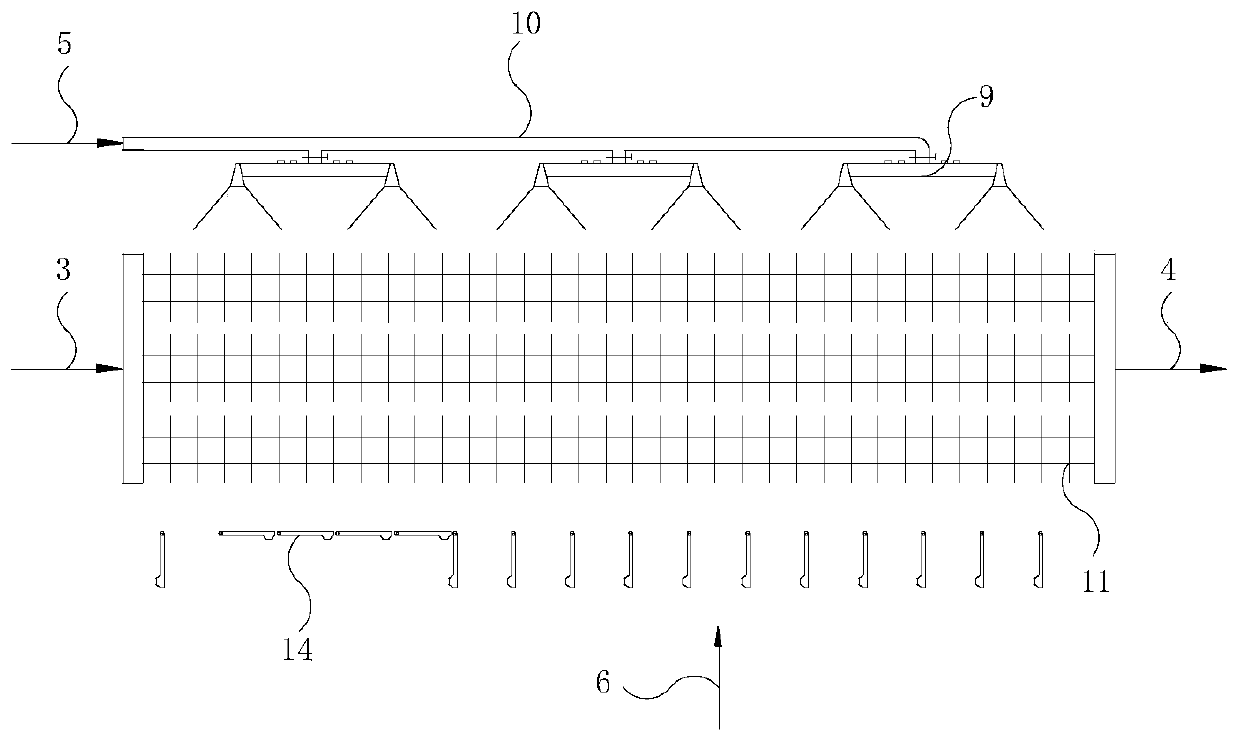

[0046] This embodiment is basically the same as Embodiment 1, the difference is that in the high temperature season, the strengthening of the cooling capacity uses water evaporation heat exchange, instead of installing a water distribution device on the upper part of the finned tube to distribute water to the fins, but at the air inlet The side is equipped with a water spray mechanism that sprays water into the air, such as Figure 6 shown. Using atomized water to evaporate in the air, the air inlet temperature can be lowered from the dry bulb to close to the wet bulb temperature. At the same time, the air entrains the sprayed water into the fin space, and the water droplets form a water film on the hydrophilic fin, which can also be realized The latent heat of water vaporization of the water film absorbs the heat and forces the evaporation heat exchange function, which obtains a higher heat extraction capacity than ordinary air cooling. Although the cooling effect of this me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com