Electronic high-temperature friction system measuring device

A systematic measurement and electric technology, applied in the direction of measuring devices, mechanical devices, instruments, etc., can solve the problems of single working condition simulation and large error of measurement values, and achieve high measurement accuracy, high precision, and improved accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but the present invention is not limited to the scope of the described examples.

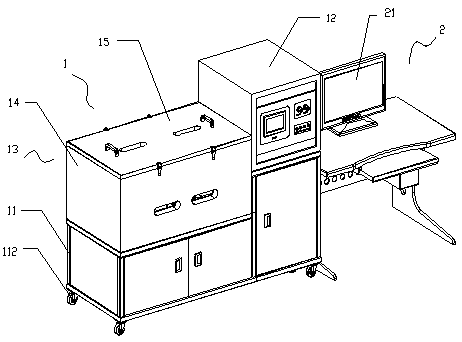

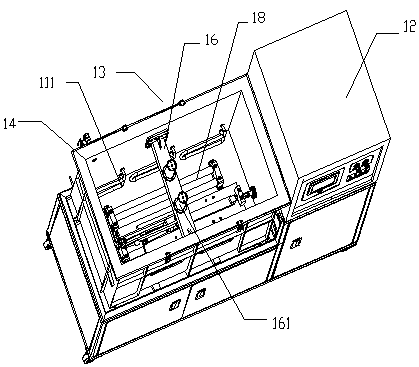

[0026] like Figure 1 to Figure 4 An electric high-temperature friction system measurement device shown includes a test system 1 and a data analysis system 2 .

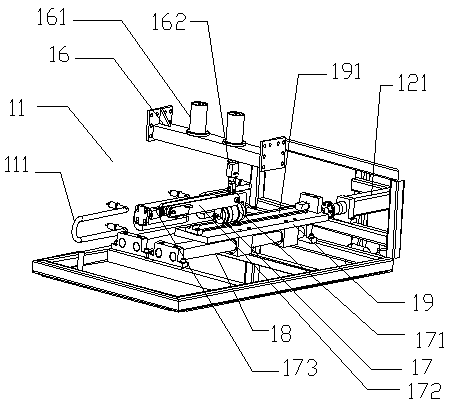

[0027] Test system 1 comprises support 11, operation box 12, test box 13; Described test box 13, operation box 12 are all installed on the support 11; Described test box 11 comprises casing 14, case cover 15, support beam 16, workpiece Jaws 17, guide rails 18 and slide blocks 19, a heating pipe 111 is arranged on the inner side wall of the box body 14; There is a hydraulic cylinder 161 driven vertically, the output end of the hydraulic cylinder 161 is provided with a pressure sensor 162;

[0028] The test workpiece a171 is driven by the hydraulic cylinder 161 to move along the vertical direction, and the pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com