Electronic paper display screen, display equipment and binding method

An electronic paper display screen and electronic paper technology, applied in the field of display technology, can solve problems such as complex manufacturing process, low yield rate, and short lifespan of good products, and achieve the effect of improving substrate utilization, improving yield rate and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] In order to improve the utilization rate of the substrate of the electronic paper display, and improve the yield rate and service life of the electronic paper display, the embodiments of the present invention provide an electronic paper display, a display device and a bonding method. In order to make the purpose, technical solution and advantages of the present invention clearer, the following examples are given to further describe the present invention in detail.

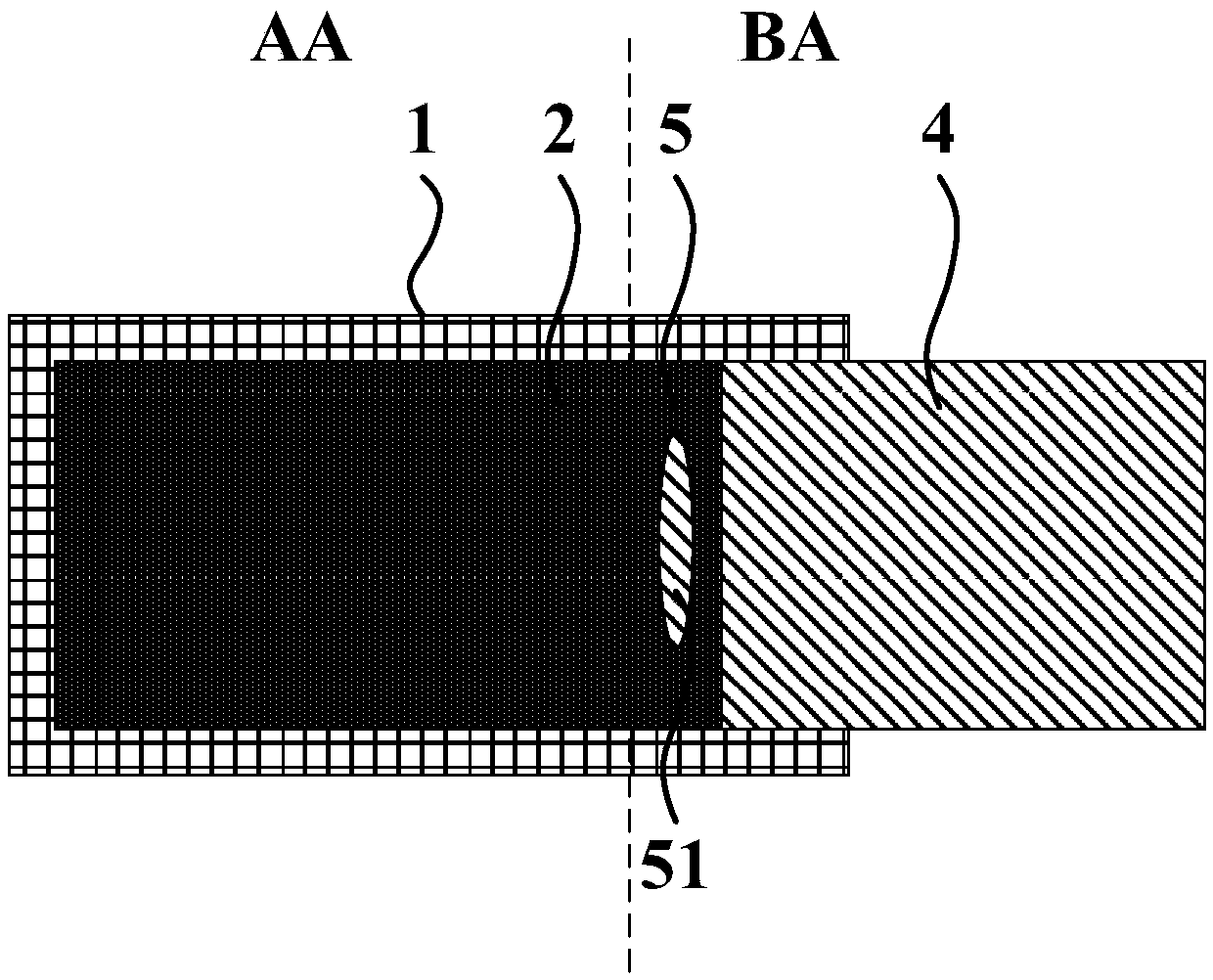

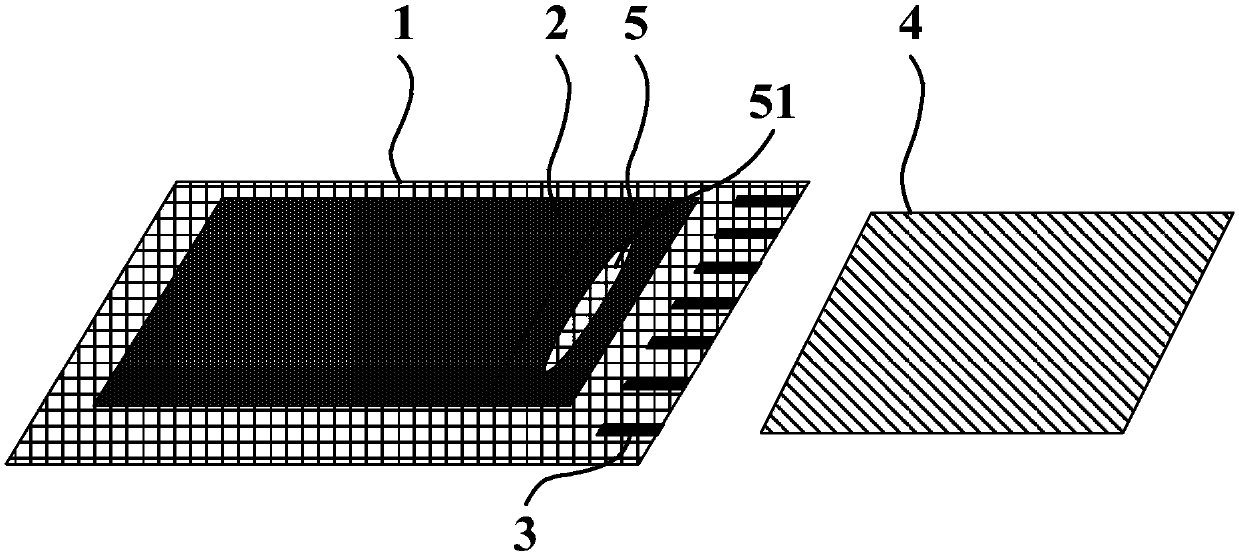

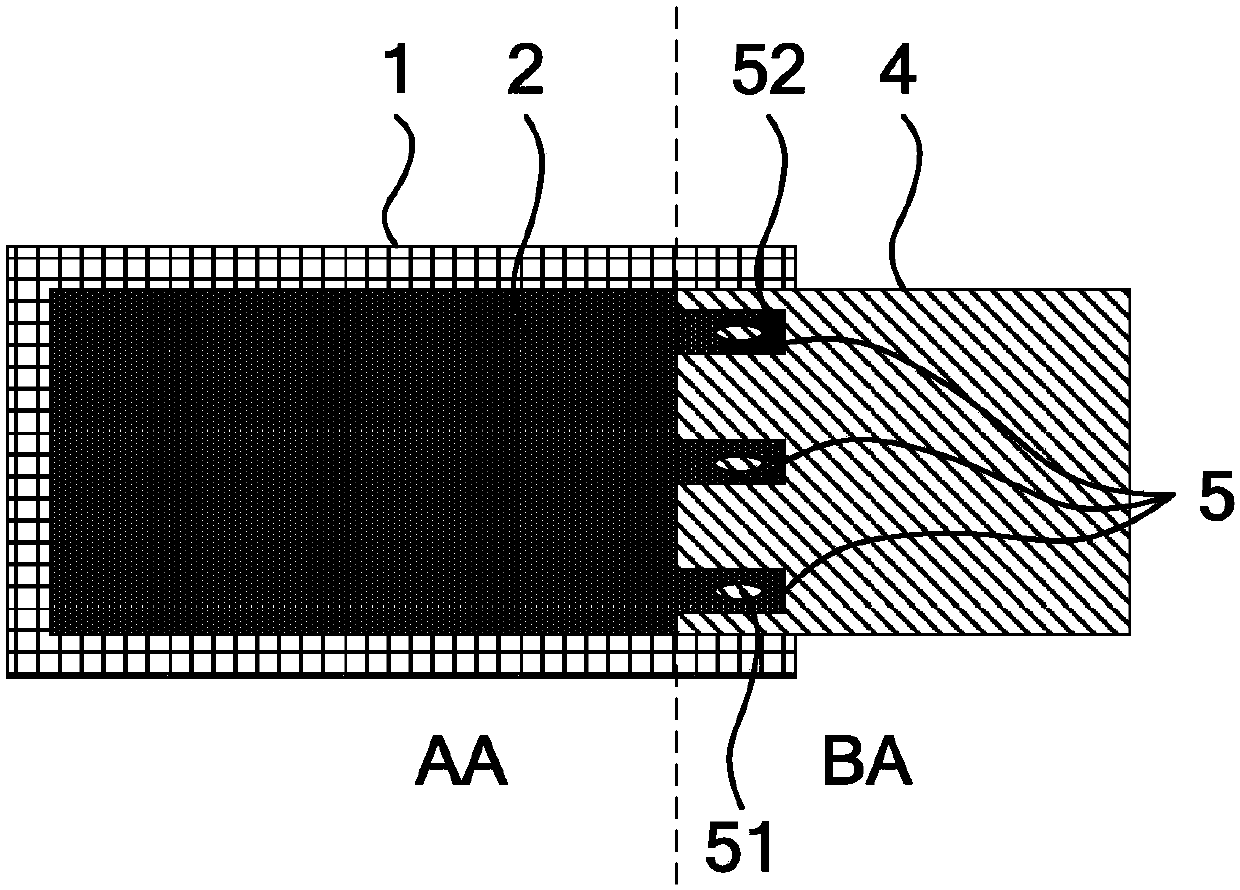

[0052] refer to figure 1 and figure 2 , a display panel detection device provided by an embodiment of the present invention includes a substrate 1, an electronic paper 2, a bonding electrode 3, an electronic ink conductive structure 5, and a chip-on-chip film 4, wherein the substrate 1 includes a display area AA and is located at At least one side of the display area AA and the bonding area BA adjacent to the display area AA, the display area AA side of the substrate 1 is provided with an electronic paper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com