A kind of production method of high-viscosity micro-molecular weight dextran

A production method and molecular weight technology, applied in microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problems of large molecular weight of glucan, loss of glucan, etc., and achieve high viscosity, saving addition, and performance. excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

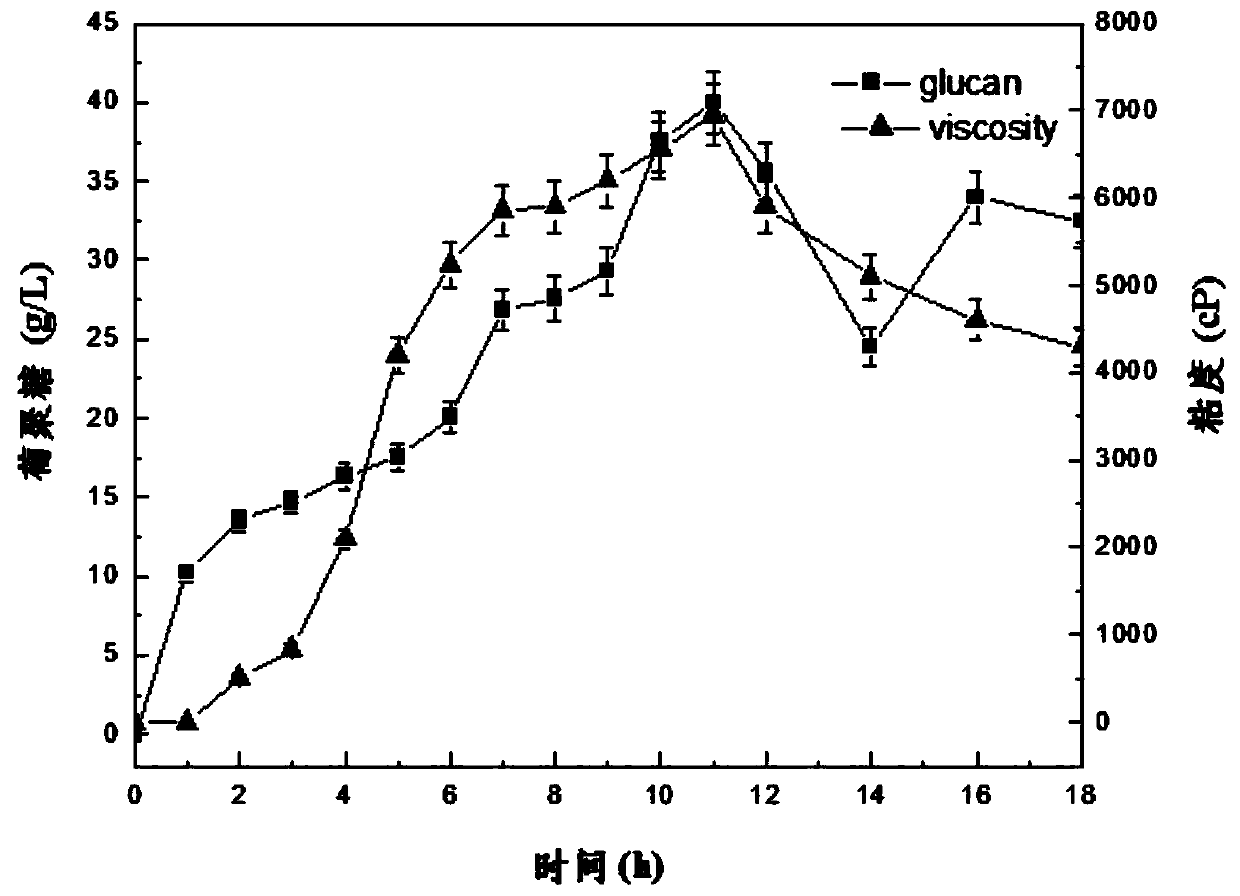

[0035] The method for producing high-viscosity micro-molecular-weight dextran by fermenting maltose as a substrate with Leuconostoc pseudoenterolis G123 comprises the following steps:

[0036] (1) Seed liquid culture:

[0037] Primary seed culture: inoculate Leuconostoc pseudoenterolis G123 bacteria liquid in a 1mL glycerol preservation tube into a test tube with a liquid volume of 5mL, and incubate at 30°C and 150rpm for 12-14h;

[0038] Secondary seed culture: Transfer from the primary seed solution to a 500mL Erlenmeyer flask with a liquid volume of 100mL at an inoculation amount of 2% (V / V), culture at 30°C, 150 rpm, for 10-12 hours;

[0039] (2) Fermentation tank culture:

[0040] Inoculate the secondary seed solution in (1) into a 3L fermenter with an inoculum volume of 8% (V / V), the liquid volume is 2L, the initial maltose concentration is 110g / L, and the initial pH is adjusted to 7.5. %NaOH is used to control the pH during the fermentation process to not be lower tha...

Embodiment 2

[0045] This example illustrates the method for producing glucan by fermentation of different substrates by Leuconostoc pseudointestinalis G123:

[0046] (1) Seed liquid culture:

[0047] Primary seed culture: inoculate Leuconostoc pseudoenterolis G123 bacteria liquid in a 1mL glycerol preservation tube into a test tube with a liquid volume of 5mL, and incubate at 30°C and 150rpm for 12-14h;

[0048] Secondary seed culture: Transfer from the primary seed solution to a 500mL Erlenmeyer flask with a liquid volume of 100mL at an inoculation amount of 2% (V / V), culture at 30°C, 150 rpm, for 10-12 hours;

[0049] (2) Fermentation tank culture:

[0050] The secondary seed solution in (1) was inoculated into a 3L fermenter with an inoculum volume of 8% (V / V), the liquid volume was 2L, the initial substrate concentration was 120g / L, and the initial pH was adjusted to 7.5 to 20% NaOH is used to control the pH during the fermentation process to not be lower than 7.0, the air is ventila...

Embodiment 3

[0053] Example 3 This example illustrates the method for producing glucan by fermentation of Leuconostoc mesenteroides G123 in different pH environments:

[0054] (1) Seed liquid culture:

[0055] Primary seed culture: inoculate Leuconostoc pseudoenterolis G123 bacteria liquid in a 1mL glycerol preservation tube into a test tube with a liquid volume of 5mL, and incubate at 30°C and 150rpm for 12-14h;

[0056]Secondary seed culture: Transfer from the primary seed solution to a 500mL Erlenmeyer flask with a liquid volume of 100mL at an inoculation amount of 2% (V / V), culture at 30°C, 150 rpm, for 10-12 hours;

[0057] (2) Fermentation tank culture:

[0058] Inoculate the secondary seed solution in (1) into a 3L fermenter with an inoculum volume of 8% (V / V), the liquid volume is 2L, and the initial concentration of maltose solution is 110g / L. ① Adjust the initial pH to 7.0, Use 20% NaOH to control the pH during the fermentation process to not be lower than 6.5; ② adjust the ini...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com