Production method for alpha-arbutin with high optical purity and glucan with high adhesion

A technology of optical purity and arbutin, applied in biochemical equipment and methods, methods based on microorganisms, microorganisms, etc., can solve problems such as poor bonding performance, and achieve high gel-forming performance, strong adhesion, and yield high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

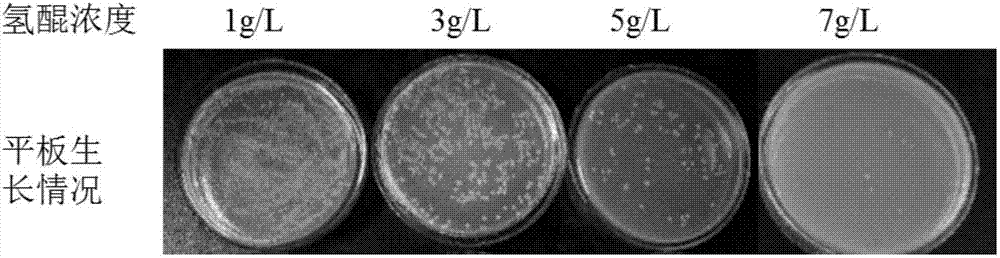

[0026] Leuconostocpseudomesenteroides (Leuconostocpseudomesenteroides) G123 was fermented in a 3L fermenter with a liquid volume of 2L, the fermentation condition was an initial pH of 6.5, the pH was controlled at 6.0 to 6.8 throughout the fermentation process, and 15g / L hydroquinone was sterilized separately and supplemented 10 times , 90g / L sucrose is sterilized separately and supplemented with hydroquinone at the same time, divided into 10 times, specifically including the following steps:

[0027] (1) Seed liquid culture:

[0028] First-level seed culture: inoculate the Leuconostoc pseudoenteritis bacteria liquid in the glycerol storage tube with an inoculum amount of 0.1-0.2% into the seed medium, and incubate at 37°C and 250rpm for 11 hours;

[0029] Secondary seed culture: transfer from the primary seed solution to the seed medium with an inoculation amount of 1-2%, and cultivate for 11 hours at 37°C and 250rpm;

[0030] The seed medium is: peptone 5.0g / L, yeast powder...

Embodiment 2

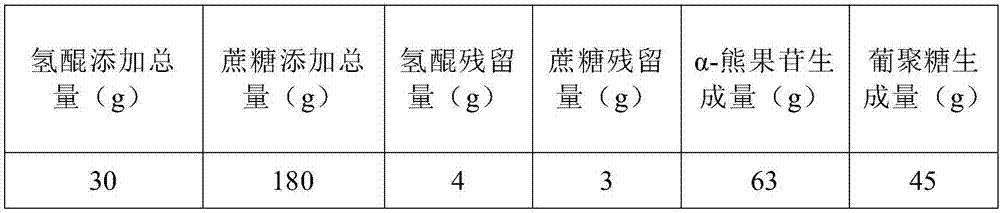

[0039] Leuconostoc pseudoenteritidis G123 was fermented in a 3L fermenter with a liquid volume of 2L. The fermentation condition was an initial pH of 6.5, and the pH was controlled at 6.0 to 6.8 throughout the fermentation process. 30g / L hydroquinone was sterilized separately and added in 10 times, 150g / L L sucrose is sterilized separately and supplemented with hydroquinone at the same time, divided into 10 times, specifically including the following steps:

[0040] (1) Seed liquid culture:

[0041] First-level seed culture: inoculate the Leuconostoc pseudoenteritis bacteria liquid in the glycerol storage tube with an inoculum amount of 0.1-0.2% into the seed medium, and incubate at 37°C and 250rpm for 10 hours;

[0042] Secondary seed culture: transfer from the primary seed solution to the seed medium with an inoculation amount of 1-2%, and cultivate for 10 hours at 37°C and 250rpm;

[0043] The seed medium is: peptone 4.0g / L, yeast powder 4.0g / L, sodium acetate 4.0g / L, Twee...

Embodiment 3

[0048] Leuconostoc pseudoenteritidis G123 was fermented in a 3L fermenter with a liquid volume of 2L. The fermentation condition was an initial pH of 6.5. The pH was controlled at 6.0 to 6.8 throughout the fermentation process. 10g / L hydroquinone was sterilized separately and added in 10 times, 80g / L L sucrose is sterilized separately and supplemented with hydroquinone at the same time, divided into 10 times, specifically including the following steps:

[0049] (1) Seed liquid culture:

[0050] First-level seed culture: inoculate the Leuconostoc pseudoenteritis bacteria solution in the glycerol storage tube with an inoculation amount of 0.1-0.2% into the seed medium, and cultivate at 37°C and 250rpm for 12 hours;

[0051] Secondary seed culture: transfer from the primary seed solution to the seed medium with an inoculation amount of 1-2%, and cultivate for 12 hours at 37°C and 250rpm;

[0052]The seed medium is: peptone 8.0g / L, yeast powder 8.0g / L, sodium acetate 8.0g / L, Twee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com