A kind of selective plugging agent and its application

A selective, chemical technology, applied in chemical instruments and methods, wellbore/well components, sealing/packaging, etc., can solve the problems of poor pumpability, short validity period, poor oil-water selectivity, etc., to achieve good pumpability, The effect of strong oil-water selectivity, high blocking rate and high erosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

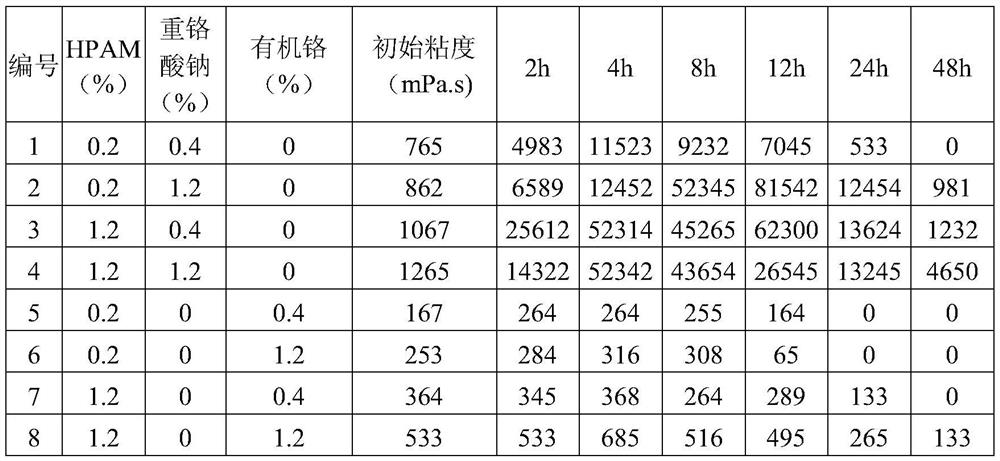

[0013] Weigh polyacrylamide, sodium dichromate, organic chromium and the remaining water according to the mass concentration percentages described in Table 1 below, and mix the above-mentioned components to obtain a selective blocking agent. The amide is anionic polyacrylamide with a molecular weight of 12 million. Through indoor experiments, the results of testing the gelling effect of 12 million anionic polyacrylamides are shown in Table 1.

[0014] Table 1

[0015]

Embodiment 2

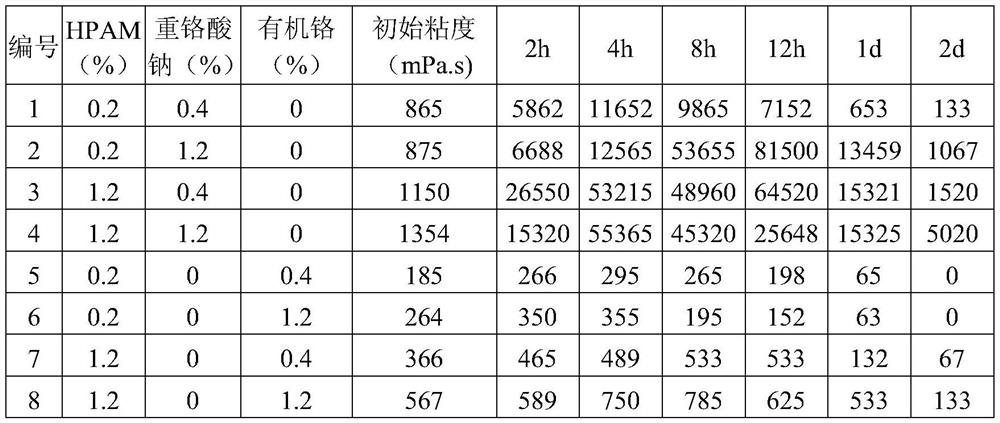

[0017] Weigh polyacrylamide, sodium dichromate, organic chromium and the remaining water according to the mass concentration percentages described in Table 2 below, and mix the above-mentioned components to obtain a selective blocking agent. The amide is an anionic polyacrylamide with a molecular weight of 17 million. Through indoor experiments, the results of testing the gelling effect of 17 million anionic polyacrylamides are shown in Table 2.

[0018] Table 2

[0019]

Embodiment 3

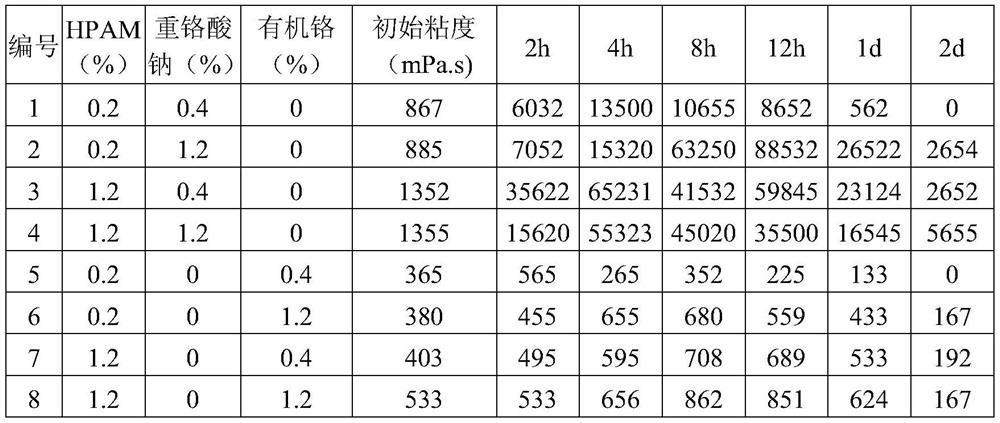

[0021] Weigh polyacrylamide, sodium dichromate, organic chromium and the remaining water according to the mass concentration percentages described in Table 3 below, and mix the above-mentioned components to obtain a selective blocking agent. The amide is an anionic polyacrylamide with a molecular weight of 19 million. Through indoor experiments, the results of testing the gelling effect of 19 million anionic polyacrylamides are shown in Table 3.

[0022] table 3

[0023]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com