Supramolecular hydrogel and preparation method thereof

A supramolecular hydrogel and compound technology, applied in the field of supramolecules, can solve problems such as low elastic modulus and poor water retention capacity, and achieve high elastic modulus, improved gel forming ability, and strong water absorption ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

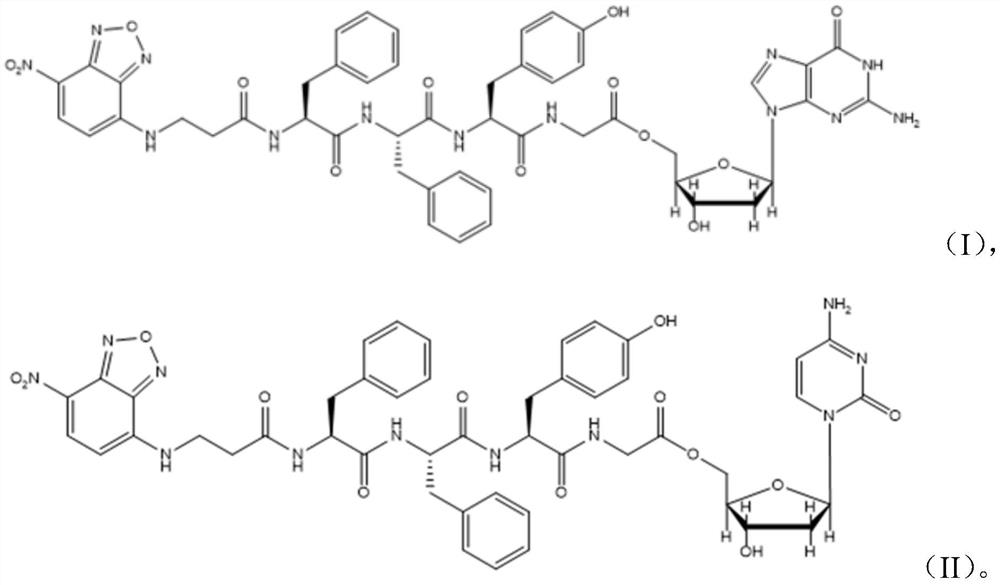

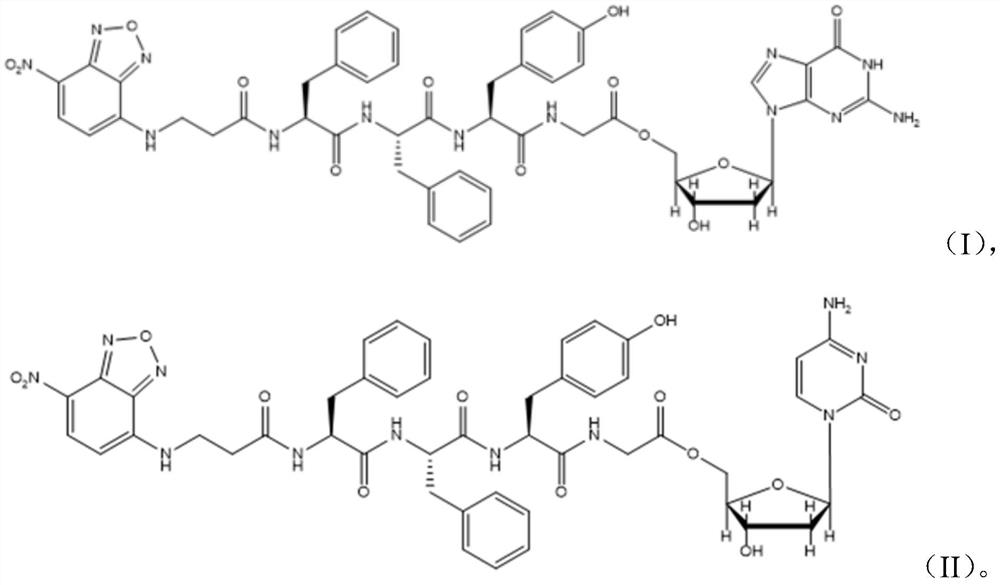

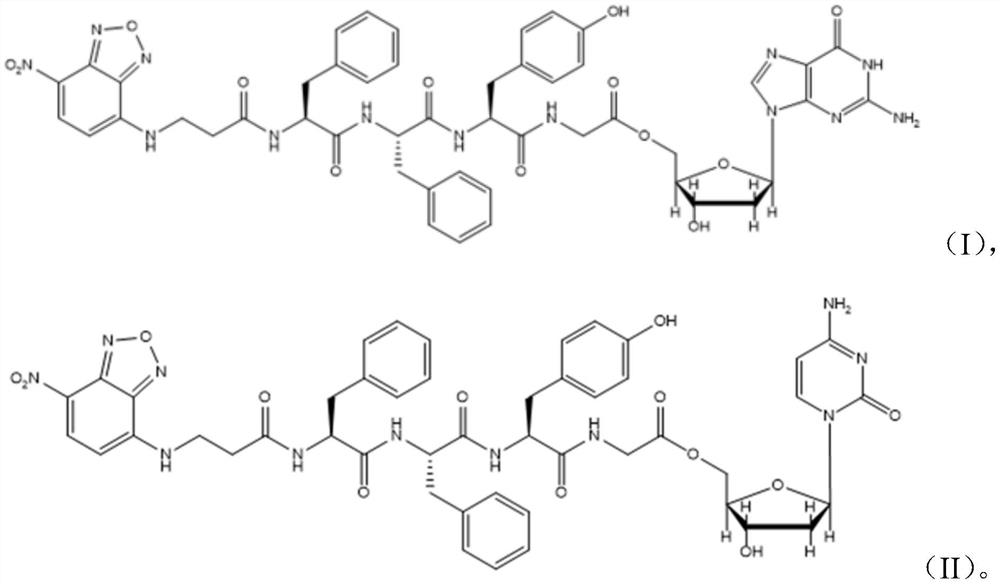

Image

Examples

Embodiment 1

[0055] (1) Add 1 g of NBD-FFYG-G to 11.5 g of distilled water and stir and mix for 1 min at a temperature of 40 ° C to prepare a solution with a concentration of 8 wt % of NBD-FFYG-G, and then add 0.002 g of α- Hydroxypropionic acid and 0.002 g of α-hydroxy n-butyric acid were magnetically stirred for 5 minutes in a water bath at 40°C to obtain a mixed solution I;

[0056] (2) Add 1 g of NBD-FFYG-C to 11.5 g of distilled water, stir for 1 min at a temperature of 24° C., and prepare a mixed solution II with a concentration of NBD-FFYG-C of 8 wt %;

[0057] (3) Mix the mixed solution I obtained in step (1) with the mixed solution II obtained in step (2), stir at 6°C for 15 minutes, and then stand at 24°C for 25 minutes to obtain supramolecular water gel.

Embodiment 2

[0059] (1) Add 1 g of NBD-FFYG-G to 19 g of distilled water and stir and mix for 0.5 min at a temperature of 35 ° C to prepare a solution with a concentration of 5 wt % of NBD-FFYG-G, and then add 0.003 g of α- Hydroxy-n-valeric acid was magnetically stirred in a water bath at 35°C for 4 minutes to obtain a mixed solution I;

[0060] (2) Add 1 g of NBD-FFYG-C to 19 g of distilled water, stir for 0.5 min at a temperature of 20° C., and prepare a mixed solution II with a concentration of NBD-FFYG-C of 5 wt %;

[0061] (3) Mix the mixed solution I obtained in step (1) with the mixed solution II obtained in step (2), stir at 4°C for 10 minutes, and then stand at 20°C for 30 minutes to obtain supramolecular water gel.

Embodiment 3

[0063] (1) Add 1 g of NBD-FFYG-G to 9 g of distilled water and stir and mix for 3 minutes at a temperature of 45 ° C to prepare a solution with a concentration of 10 wt % of NBD-FFYG-G, and then add 0.005 g of α-hydroxyl Propionic acid, stirred magnetically for 6 minutes in a water bath at 45°C to obtain a mixed solution I;

[0064] (2) Add 1 g of NBD-FFYG-C to 9 g of distilled water, stir for 3 min at a temperature of 30° C., and prepare a mixed solution II with a concentration of NBD-FFYG-C of 10 wt %;

[0065] (3) Mix the mixed solution I obtained in step (1) with the mixed solution II obtained in step (2), stir at 8°C for 20 minutes, and then stand at 30°C for 20 minutes to obtain supramolecular water gel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com