A kind of acid fracturing fluid and its preparation method and application

A fracturing fluid and acidic technology, which is applied in chemical instruments and methods, earthwork drilling, wellbore/well components, etc., can solve the problems of large amount of thickening agent, large formation damage, and high residue, so as to reduce the amount and suppress Damage, the effect of improving gelation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

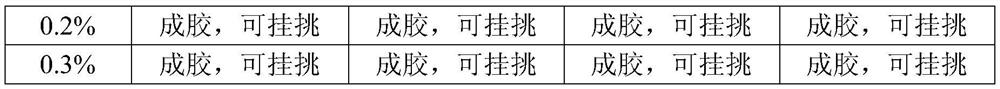

Examples

Embodiment 1

[0030] Preparation of crosslinking agent:

[0031] Warm up 100 parts by weight of deionized water to 50°C, add 10 parts by weight of zirconium oxychloride, 0.25 parts by weight of sodium chloride, and 0.025 parts by weight of ammonium chloride, stir at a speed of 20-40 rpm, and wait for the oxychloride to After the zirconium is completely dissolved, add 30 parts by weight of ethylene glycol and stir at a speed of 20-40 rpm. After fully dissolving, continue to add 15 parts by weight of lactic acid, and then drop in 20% concentration of sodium hydroxide lye to adjust the pH When the value reaches 6, react at constant temperature for 8 hours to obtain a colorless and transparent organic zirconium crosslinking agent.

Embodiment 2

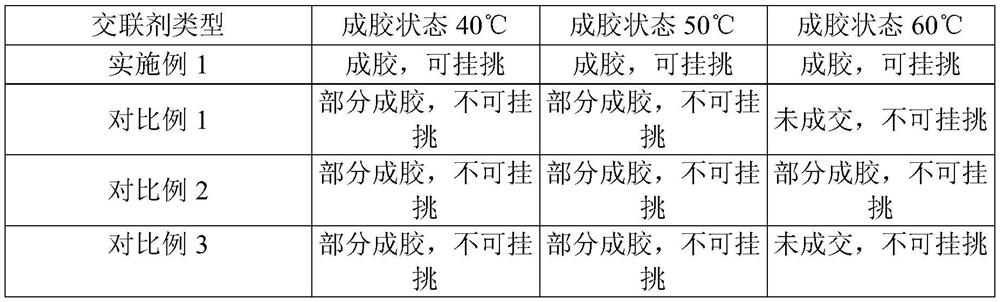

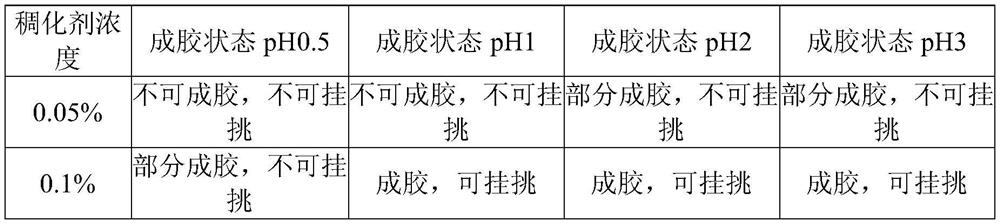

[0039] Gelling properties at different pH values

[0040] The organozirconium cross-linking agent of Example 1 is used for performance evaluation of water-based fracturing fluid. The test conditions are: water-based liquid preparation, thickening agent is carboxymethyl hydroxypropyl guar gum, cross-linking agent dosage 0.3%, pH They are 0.5, 1, 2, 3 respectively, and the temperature is 60°C. The results are shown in Table 2.

[0041] Table 2

[0042]

[0043]

[0044] It can be seen from Table 2 that the use of carboxymethyl hydroxypropyl guar gum allows the acidic fracturing fluid to gel at a concentration of 0.1% and a pH of 1 to form a fracturing fluid system that meets the application requirements.

Embodiment 3

[0046] The preparation method of modified carboxymethyl hydroxypropyl guar gum:

[0047] 10 parts by weight of carboxymethyl hydroxypropyl guar gum are dissolved in 100 parts by weight of deionized water, stirred and dissolved to obtain carboxymethyl hydroxypropyl guar gum solution;

[0048] 0.25 parts by weight of N-isopropylacrylamide and 0.25 parts by weight of acrylic acid were dissolved in 20 parts by weight of deionized water and placed in a dropping funnel for use to obtain a monomer solution.

[0049]Add 0.01 part by weight of initiator (ammonium persulfate + sodium sulfite) to carboxymethyl hydroxypropyl guar gum solution, stir to dissolve, heat up to 50°C, then add monomer solution dropwise, react for 5 hours, add ethanol to precipitate the product.

[0050] Suction filter the product, wash with ethanol solvent, and dry to obtain modified carboxymethyl hydroxypropyl guar gum.

[0051] Characterization of Modified Carboxymethyl Hydroxypropyl Guar Gum

[0052] The mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com