Method for producing methane by synergistic treatment of biogas slurry and biogas based on microbial electrocatalysis

A technology of microbial electrochemistry and microbial electricity, applied in the field of green energy, can solve the problems of secondary pollution by by-products, high investment and operating costs, low economic efficiency, and low feasibility, so as to reduce carbon emissions and improve energy efficiency Effect

Active Publication Date: 2022-05-31

CHINESE RES ACAD OF ENVIRONMENTAL SCI

View PDF4 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

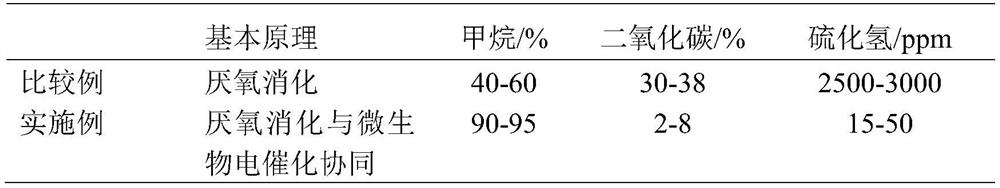

At present, the relatively mature biogas upgrading methods mainly include physical, chemical and biological technologies, which are mainly suitable for large-scale biogas projects. For decentralized, medium and small-scale biogas projects, the economy and feasibility are not high, and the purification process will produce secondary products such as by-products. Pollution, which increases process complexity, leads to high investment and operating costs, and seriously affects biogas applications

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0034]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

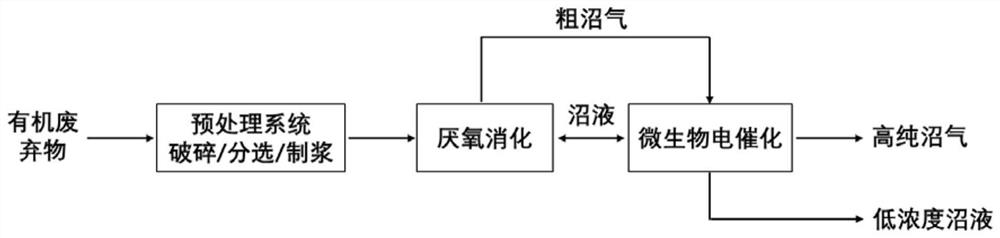

A method for biogas slurry advanced treatment and biogas upgrading to prepare methane based on microbial electrocatalysis. The biogas slurry is used to start the microbial electrochemical system, and the volatile fatty acids and refractory organic compounds in the biogas slurry are degraded under the action of anode electroactive microorganisms. And cooperating with sulfur-oxidizing microorganisms to oxidize hydrogen sulfide in raw biogas to polysulfides, while polysulfides act as redox shuttles to transfer electrons and protons generated at the anode to the cathode, and reduce them in the crude biogas under the action of methanogenic microorganisms at the cathode The carbon dioxide is methane, which realizes the simultaneous completion of advanced treatment of high-concentration biogas slurry, desulfurization and decarbonization of biogas.

Description

Method for preparing methane by co-processing of biogas slurry and biogas based on microbial electrocatalysis technical field The invention belongs to the field of green energy, be specifically related to a kind of based on microbial electrocatalysis principle, synchronously realize biogas Method for preparing methane by liquid treatment and biogas upgrading. Background technique At present, the output and quantity of biogas projects in our country rank first in the world, and more than 90% of them adopt wet anaerobic digestion. It is the mainstream process of green energy conversion of organic waste. However, the energy conversion efficiency of the existing wet anaerobic digestion process is low, A large amount of biogas slurry produced by fermentation is difficult to be absorbed by land, and most of them are treated as leachate, which has complicated treatment process and high cost; The methane content of the biogas is only 50%-70%, carbon dioxide is as high as 25...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C12P5/02C02F3/00C02F3/28C12R1/01

CPCY02E50/30

Inventor 李鸣晓席北斗王勇亓雪娇徐沛侯佳奇叶美瀛

Owner CHINESE RES ACAD OF ENVIRONMENTAL SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com