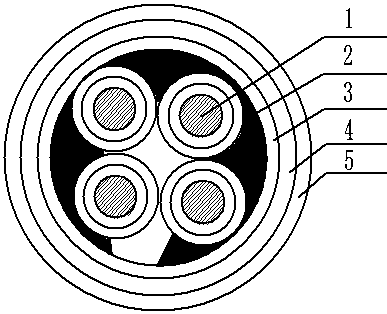

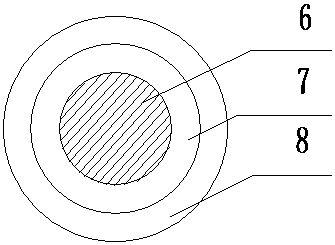

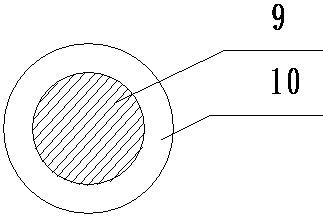

Fire-resisting cable with high strength and pressure resisting for ship and preparation method thereof

A fire-resistant cable, high-strength technology, used in cable/conductor manufacturing, insulating cables, insulating conductors/cables, etc., can solve problems such as defective tensile performance, poor lateral pressure resistance, and insufficient fire resistance. High tensile strength, protection strength, good fire resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A method for preparing a high-strength and pressure-resistant fire-resistant cable for ships, comprising the steps of:

[0043] (1) Preparation of a single cable core:

[0044] a. For the conductor single wire required by the small drawing machine, 18% of drawing oil and 82% of water are mixed together to make drawing oil, and 0.08% of drawing oil and 99.2% of water are mixed together to make stewing oil. The single wire of 3.00mm is drawn into a single wire of 2.53mm by multiple wire drawing of 2.80mm, 2.56mm, and 2.53mm. The air pressure in the automatic annealing process is 2.4Mpa, the coefficient voltage is 24.5V, the coefficient current is 900A, and the line speed is 150m / min; the drawn conductor single wires are respectively rewound in corresponding quantities on the rewinding machine, and stranded by the tube stranding machine to make the conductor of the cable. The stranding pitch ratio of the conductor is 14 times the outer diameter of the conductor, and the s...

Embodiment 2

[0060] A method for preparing a high-strength and pressure-resistant fire-resistant cable for ships, comprising the steps of:

[0061] (1) Preparation of a single cable core:

[0062] a. For the conductor single wire required by the small drawing machine, 19% of wire drawing oil and 81% of water are mixed together to make wire drawing oil, and 0.09% of wire drawing oil and 99.1% of water are mixed together to make stewing oil, from which The single wire of 3.00mm is drawn into a single wire of 2.53mm by multiple wire drawing of 2.80mm, 2.56mm, and 2.53mm. The air pressure in the automatic annealing process is 2.45Mpa, the coefficient voltage is 26.0V, the coefficient current is 950A, and the line speed is 200m / min; the drawn conductor single wires are respectively rewound in corresponding quantities on the rewinding machine, and stranded by a tube stranding machine to make a cable conductor. The stranding pitch ratio of the conductor is 15 times the outer diameter of the cond...

Embodiment 3

[0078] A method for preparing a high-strength and pressure-resistant fire-resistant cable for ships, characterized in that it comprises the following steps:

[0079] (1) Preparation of a single cable core:

[0080] a. For the conductor single wire required by the small drawing machine, 20% of drawing oil and 80% of water are mixed together to make drawing oil, and 0.10% of drawing oil and 99.0% of water are mixed together to make stewing oil, from which The single wire of 3.00mm is drawn into a single wire of 2.53mm by multiple wire drawing of 2.80mm, 2.56mm, and 2.53mm. The air pressure in the automatic annealing process is 2.5Mpa, the coefficient voltage is 27.0V, the coefficient current is 1000A, and the line speed is 250m / min; the drawn conductor single wires are respectively rewinded by the corresponding number on the rewinding machine, and stranded by the tube stranding machine to make the conductor of the cable. The stranding pitch ratio of the conductor is 16 times th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com