Fluoroplastic anti-internal damage cable

A fluoroplastic and fluoroplastic insulating layer technology, which is applied in the direction of insulated cables, cables, circuits, etc., can solve the problems of cable layer disorder, cable scrapping, damage, etc., and achieve the effect of reducing cost and loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

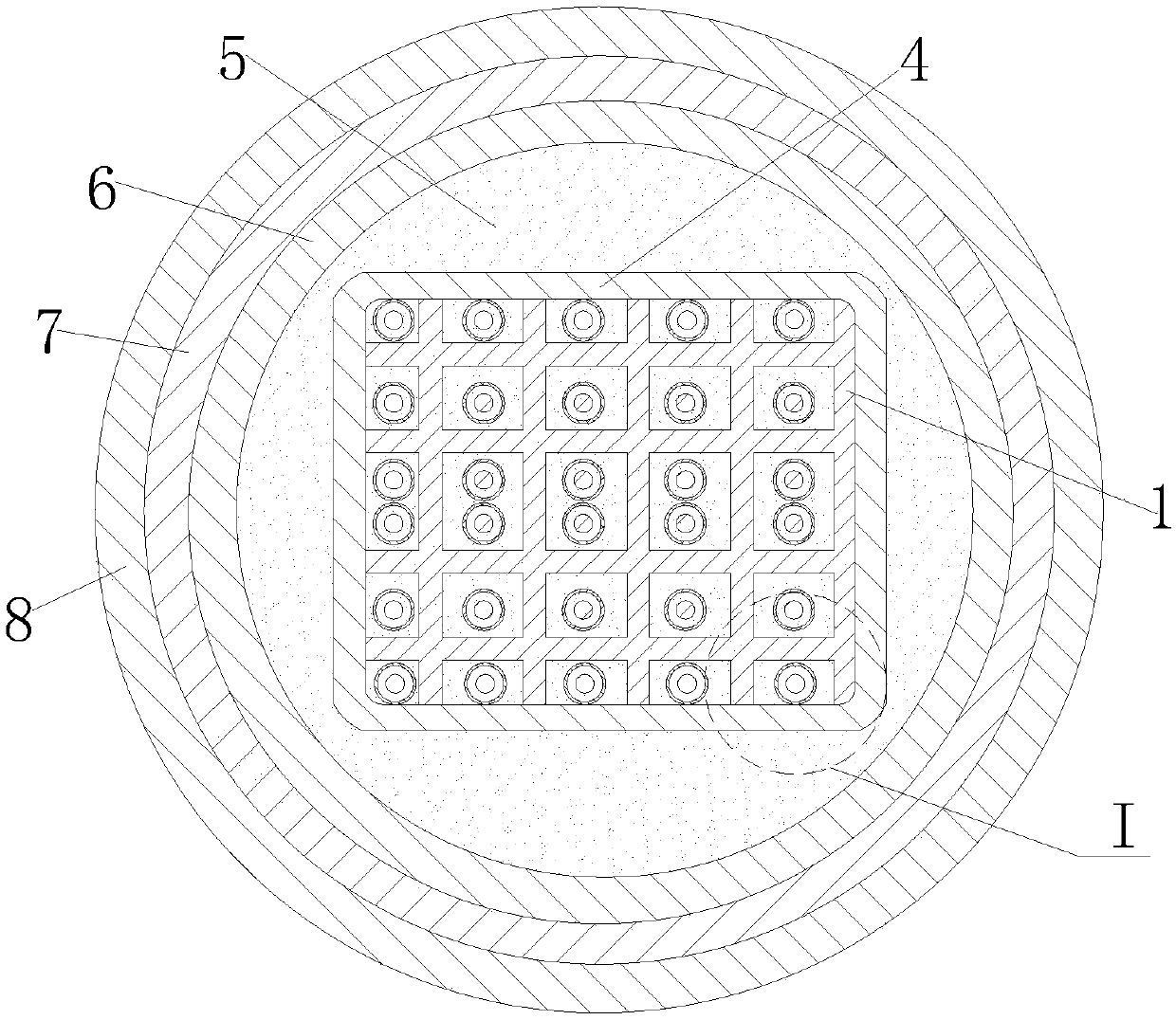

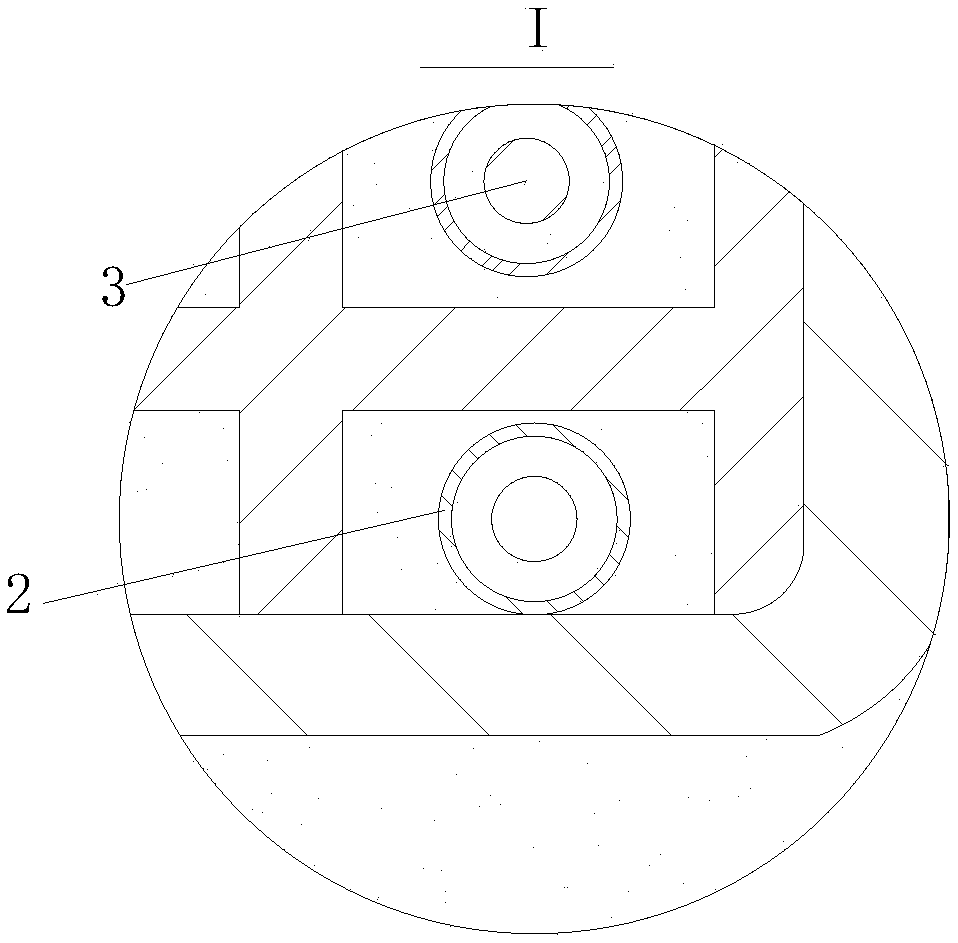

[0012] like figure 1 and figure 2 As shown, a fluoroplastic anti-internal damage cable includes several cable cores, the cable core includes a conductor 3, and the outer part of the conductor 3 is extruded with a fluoroplastic insulating layer 2, and the fluoroplastic insulating layer 2 is wrapped with a tin foil shielding layer 1, and the exterior of the tin foil shielding layer 1 is wrapped with a metal armor layer 4. The cross section of the metal armor layer 4 is a square shape that is convenient for preventing internal damage in all directions. The cross-section of the tin foil shielding layer 1 is a mesh with strong resistance to mechanical force, the outside of the metal armor layer 4 is wrapped with a copper wire braid 6, and the outside of the copper wire braid 6 is wrapped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com