A positioning type automatic folding and splitting machine

A fully automatic, board-splitting machine technology, applied in the direction of printed circuit, electrical components, printed circuit manufacturing, etc., can solve the problems of high price, complex laser cutting programming, lack of full automation, etc., to reduce damage, realize automatic operation, good The effect of height variation and shape diversity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

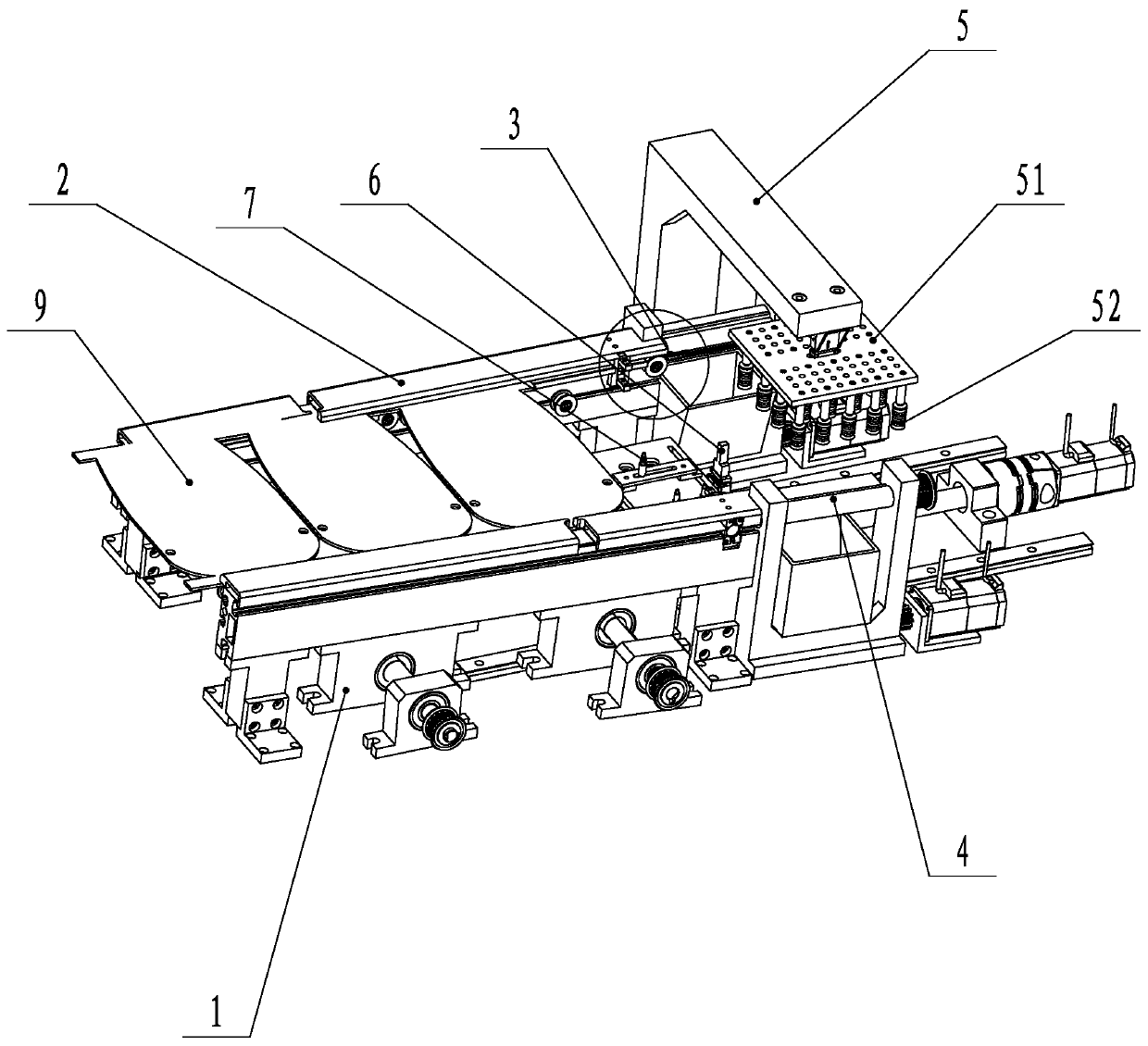

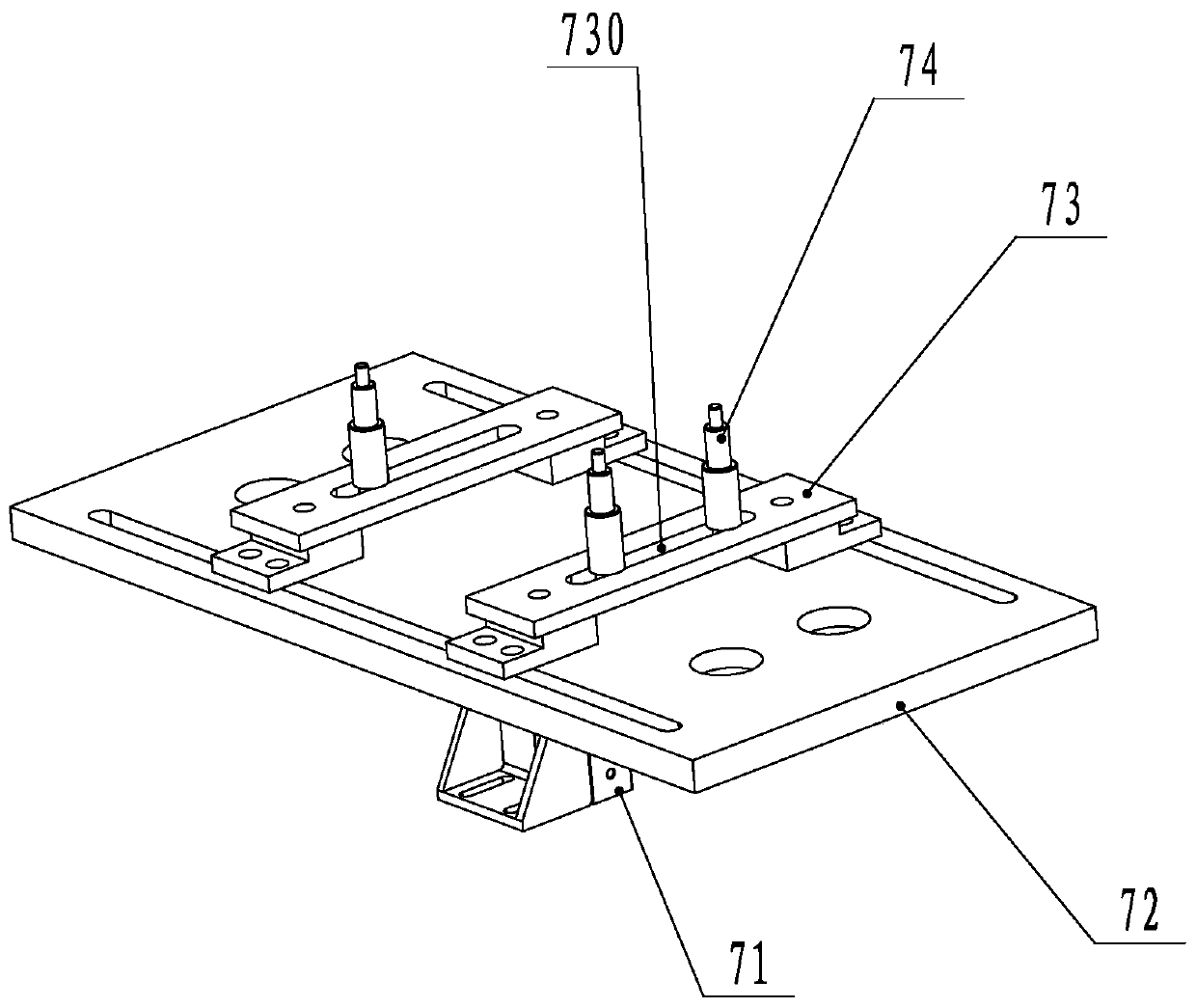

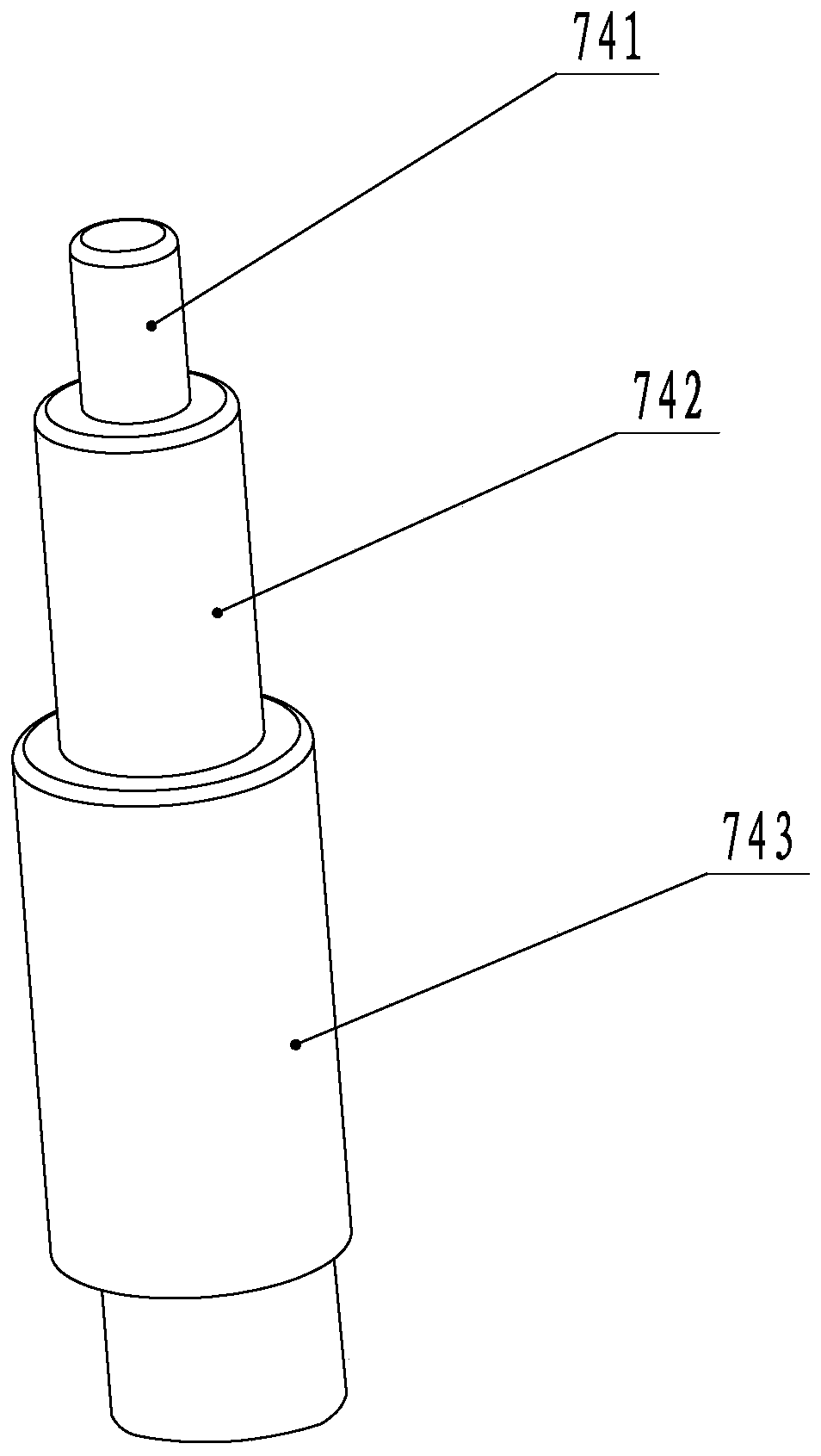

[0029] refer to Figure 1 to Figure 8 , a positioning type full-automatic folding and splitting machine of the present invention comprises a frame 1 on which a conveying device 2, a positioning device, a guiding and fixing device 3 and an edge folding device 4 are sequentially arranged, and the conveying The device 2 is provided with a rail 21 that clamps and transports the two sides of the PCB board 9 to the front end of the positioning device. The transmission device 2 can adopt chain belt transmission, steel claw clamping transmission, etc., and is not fixed. The present invention adopts friction The positioning device includes a baffle mechanism 6 and a hole pin positioning mechanism 7. After the baffle mechanism 6 blocks the PCB board 9 delivered by the conveying device 2, it is blocked by multiple holes on the hole pin positioni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com