A spray feeding machine for livestock breeding

A technology for driving a motor and a main body, applied in the field of animal husbandry, can solve the problems of affecting the quality of livestock meat, equipment being easily trampled by livestock, excessive intake of drugs, etc., and achieving the effects of easy promotion, improved feeding effect, and improved uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

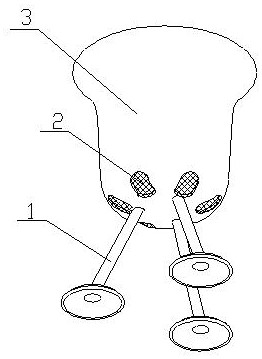

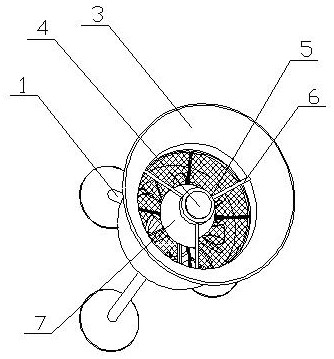

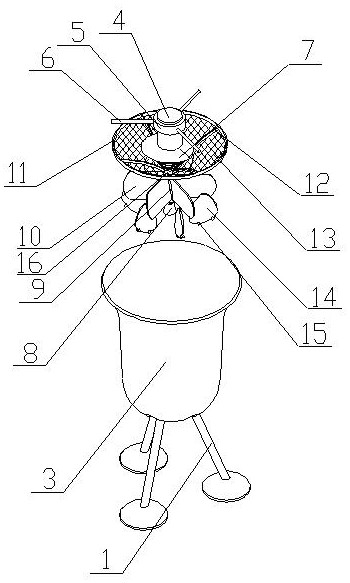

[0025] A spray feeding machine for livestock breeding of the present invention is realized in this way. When in use, when feeding livestock, the present invention is first suspended above the livestock through three brackets (1), and then roughage, auxiliary materials And the water is put into the main cylinder (3) in turn, the drive motor (4) works, the motor shaft drives the screw blade (7) to rotate, and drives the rotating rod (9) to rotate, and the screw blade (7) rotates against the main cylinder (3) The coarse feed, auxiliary materials and water in the machine are stirred and mixed, and it is driven to move down along the spiral blade (7), and the rotating rod (9) drives the cutting net (13) to rotate through the connecting ring (16), and the mixed bulk feed Falling on the cutting net (13), the cutting net (13) rotates and cuts into small pieces, then falls down through the mesh holes on the cutting net (13), and falls on the bottom of the main cylinder (3). At the same ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com