Detachable electromagnetic edge-pressing drawing die and control method for edge-pressing force of detachable electromagnetic edge-pressing drawing die

A technology for deep drawing dies and control methods, applied in electrical program control, program control in sequence/logic controllers, forming tools, etc., can solve problems such as the inability to remove the influence of mechanical pressure on blank holder force, and achieve compact structure , flexible and precise adjustment, and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation of the present invention will now be described with reference to the accompanying drawings, but it is only a preferred embodiment and is not used to limit the essential scope of the present invention.

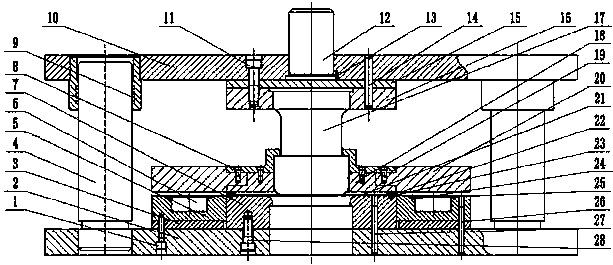

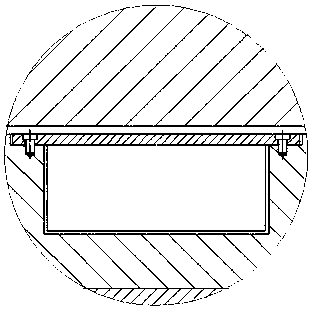

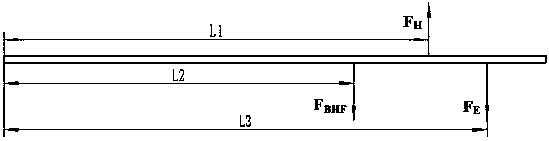

[0030] figure 1 It is a schematic diagram of the mold structure of the present invention, and the detachable electromagnetic clamping device includes a set screw 1, an upper mold base 2, an adjusting gasket 3, a guide post 4, a fixing ring 5, an electromagnetic coil 6, and a die 7, Set screw 8, die sleeve 9, upper die holder 10, set screw 11, die handle 12, positioning pin 13, cylindrical pin 14, backing plate 15, punch fixing plate 16, punch 17, blank holder ring 18, Connecting plate 19, magnetic ring 20, sheet material 21, limit plate 22, set screw 23, set screw 24, magnetic isolation plate 25, cylindrical pin 26, cylindrical pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com