Simulation device for solidification of molten steel in continuous casting crystallizer under function of electric pulses

A technology for continuous casting mold and solidification simulation, which is applied in the field of steel continuous casting and can solve problems such as undiscussed influences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the drawings and specific embodiments.

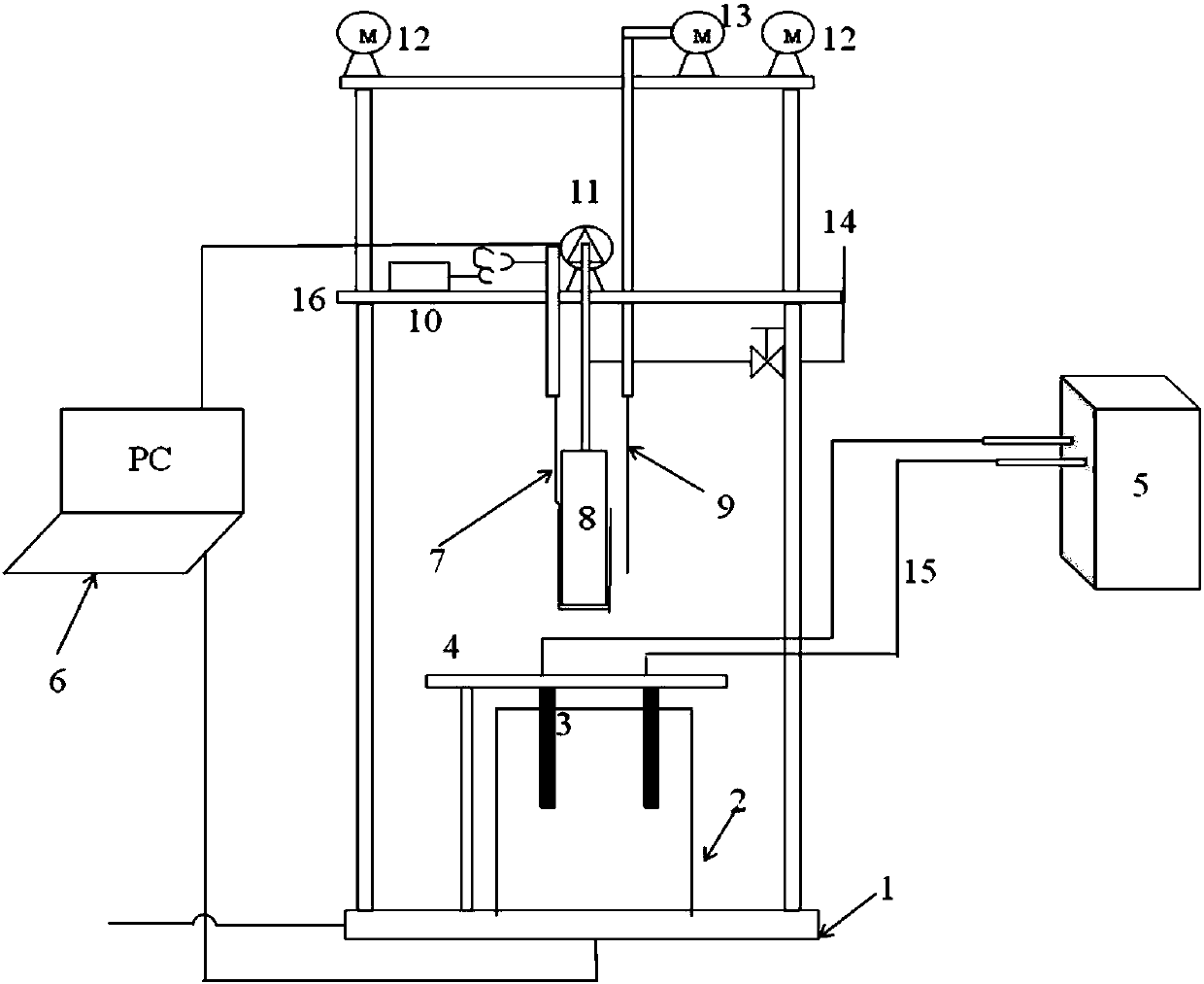

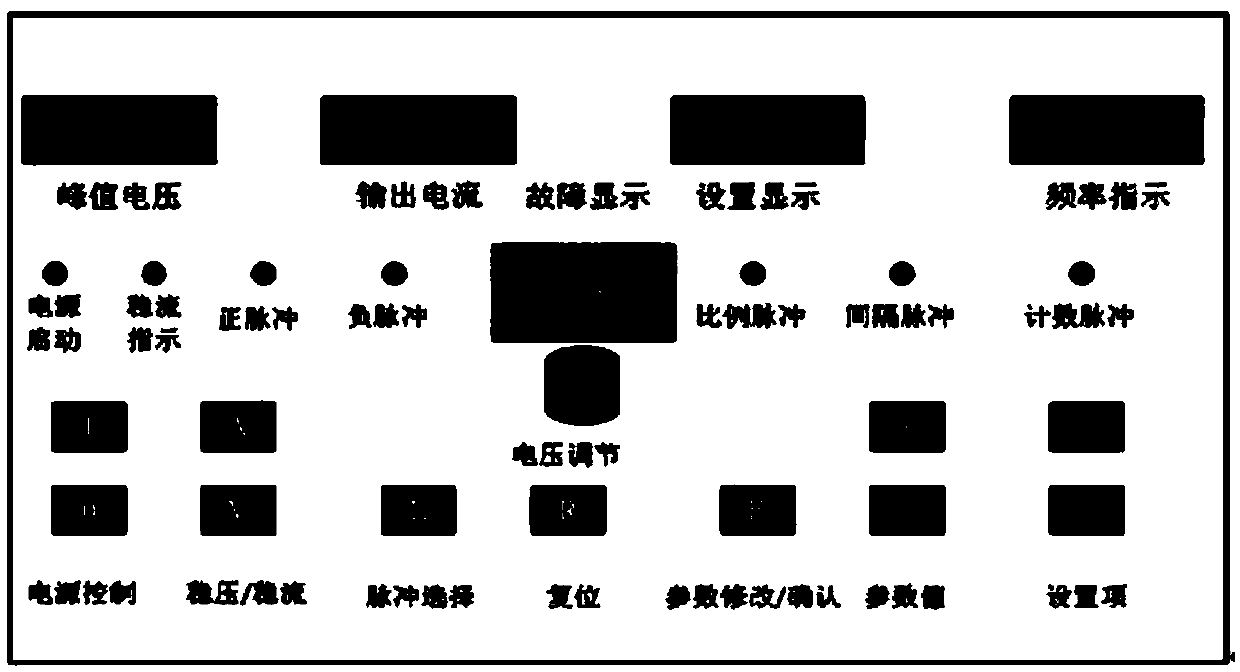

[0026] See figure 1 with figure 2 , Under the action of electric pulse, the molten steel solidification simulation device in the continuous casting mold, including the frame 1, the induction furnace 2, the electric pulse system, the data acquisition system 6, the blanking device 7, the mold 8, the positioning electrode 9, and the blanking motor 10. Vibration motor 11 and positioning motor 13. The base 1 is provided with two first screw rods and a second screw rod with one end perpendicular to the plane of the base and the other end connected to the top plate. The top plate is provided with a driving first screw rod The downward motor 12 that moves with the second screw rod is provided with a lifting bracket 16 that is driven by the first screw rod and the second screw rod to move in the vertical direction on the first screw rod and the second screw rod; the i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com