Cutter changing platform used for TMB positive hobbing cutter

A platform and forward rolling technology, applied in the TBM field, can solve the problems of difficult operation, harsh underground working environment, large manpower, material resources, financial resources and time consumption, etc., to achieve convenient tool change process, simplify the tool change process, save change The effect of knife time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and specific embodiments, and the described specific embodiments are only used to explain the present invention, and are not intended to limit the present invention.

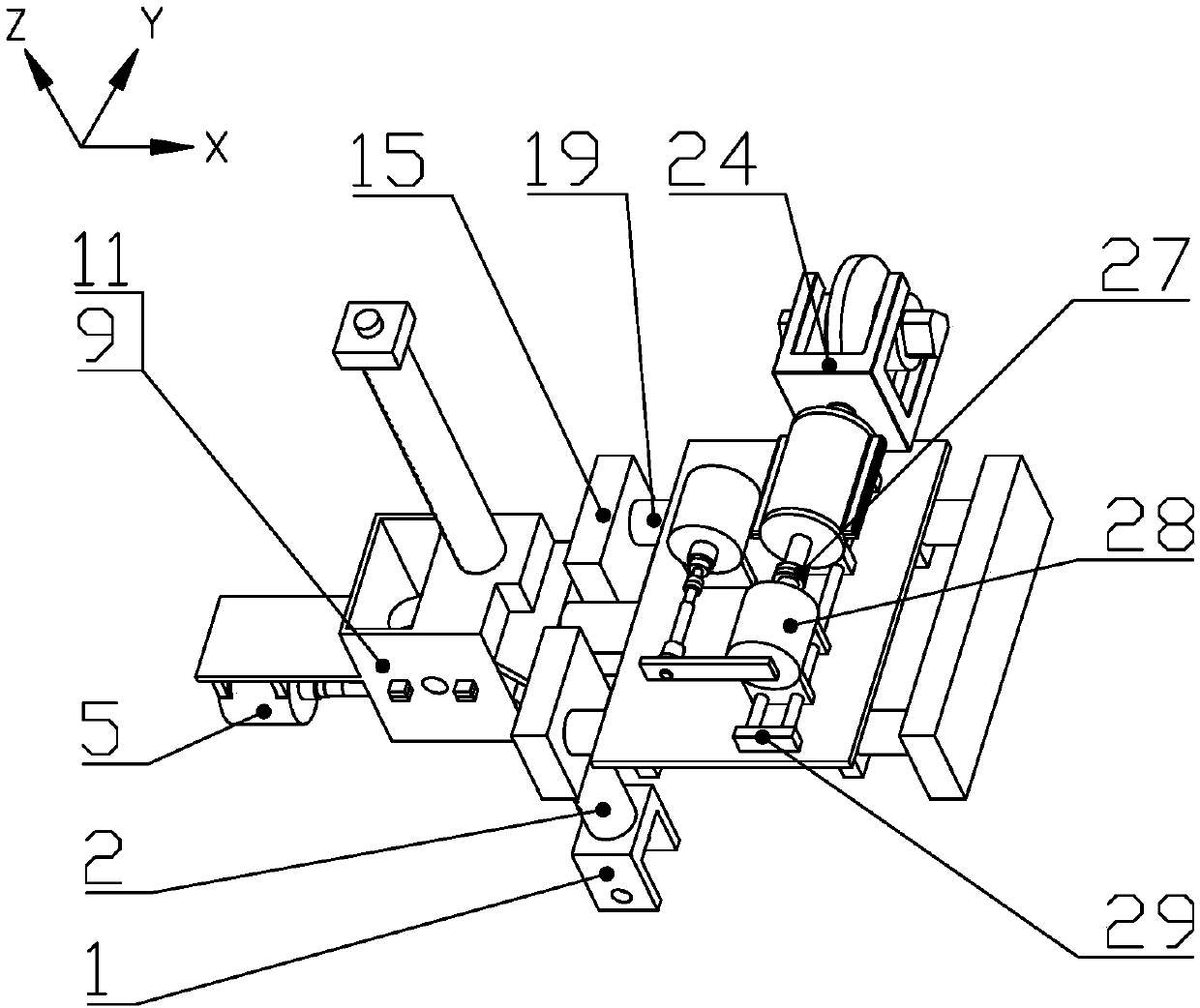

[0033] like figure 1 As shown, a tool changing platform for a TBM positive hob proposed by the present invention includes a hob clamping jaw 24 for installing the hob 36 (such as Figure 10-1 and Figure 10-2 shown), a connecting seat 1 for connecting with the equipment, a Z-axis direction motion unit, an X-axis direction motion unit and a Y-axis direction motion unit.

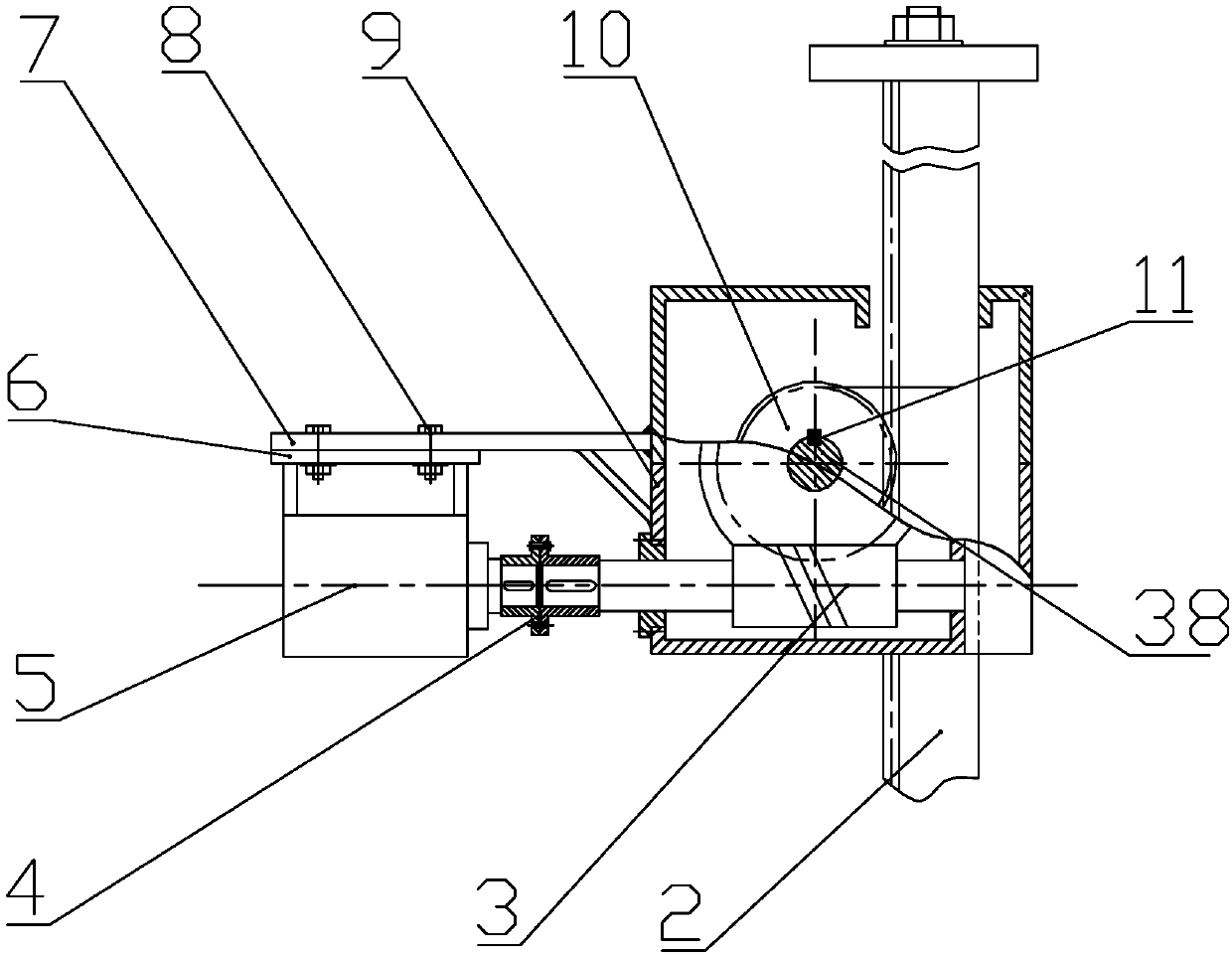

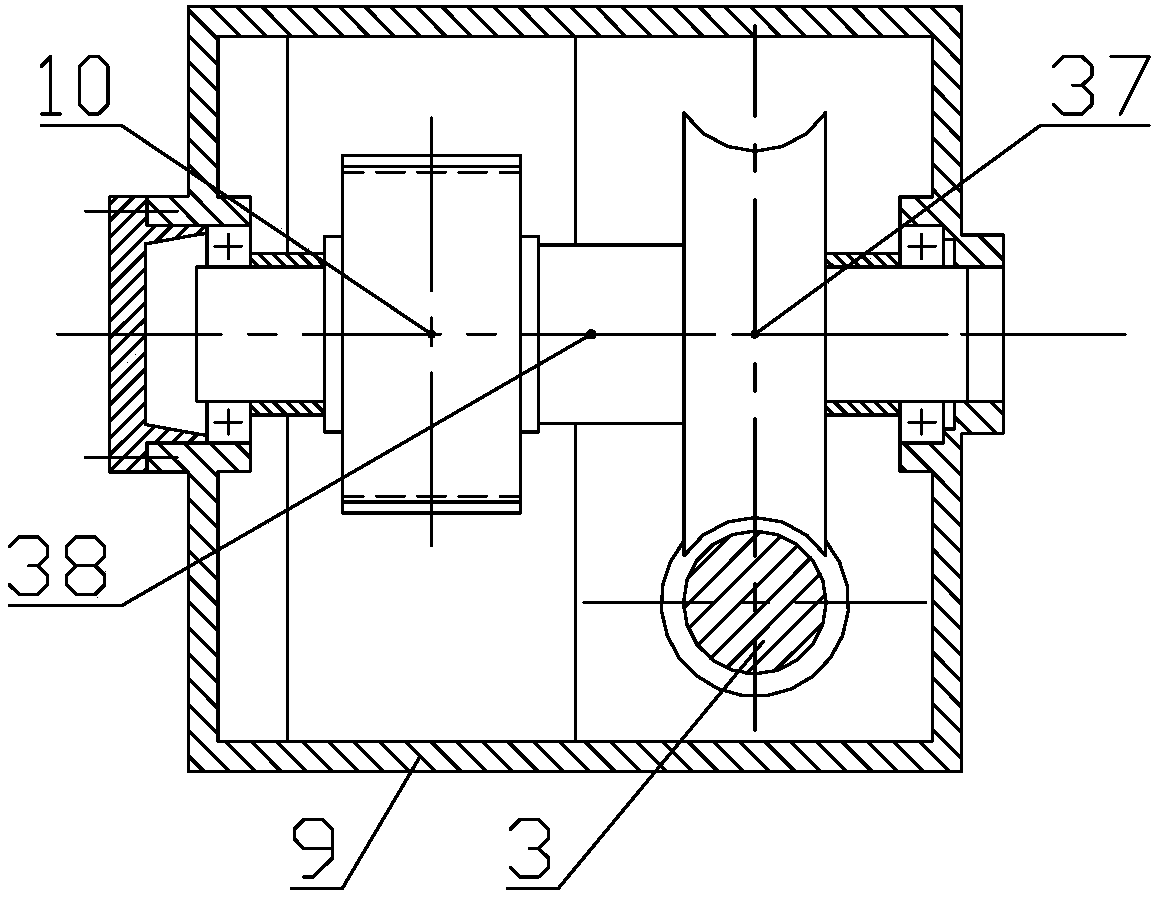

[0034] like figure 1 , figure 2 and image 3 As shown, the movement unit in the Z-axis direction includes a transmission box 9, and a first motor 5 is fixed on the outside of the transmission box 9. The first motor 5 is mounted on a support plate 7 through the motor seat 6, and the support The plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com