Wooden hanger shape molding and processing system

A processing system and technology for wooden hangers, which are applied in wood processing utensils, manufacturing tools, multi-purpose machinery, etc., can solve the problems of easy aging, poor durability and poor bearing strength of plastic hangers, so as to improve the processing efficiency and reduce work. The effect of labor intensity and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with specific embodiments; the following examples will help to further understand the present invention, but do not limit the content of the present invention. The processing part 18 described in the specification represents a wooden clothes hanger processing part, which is a wooden slab blank in the initial stage of processing, and its meaning is the same, that is, it all represents the same meaning.

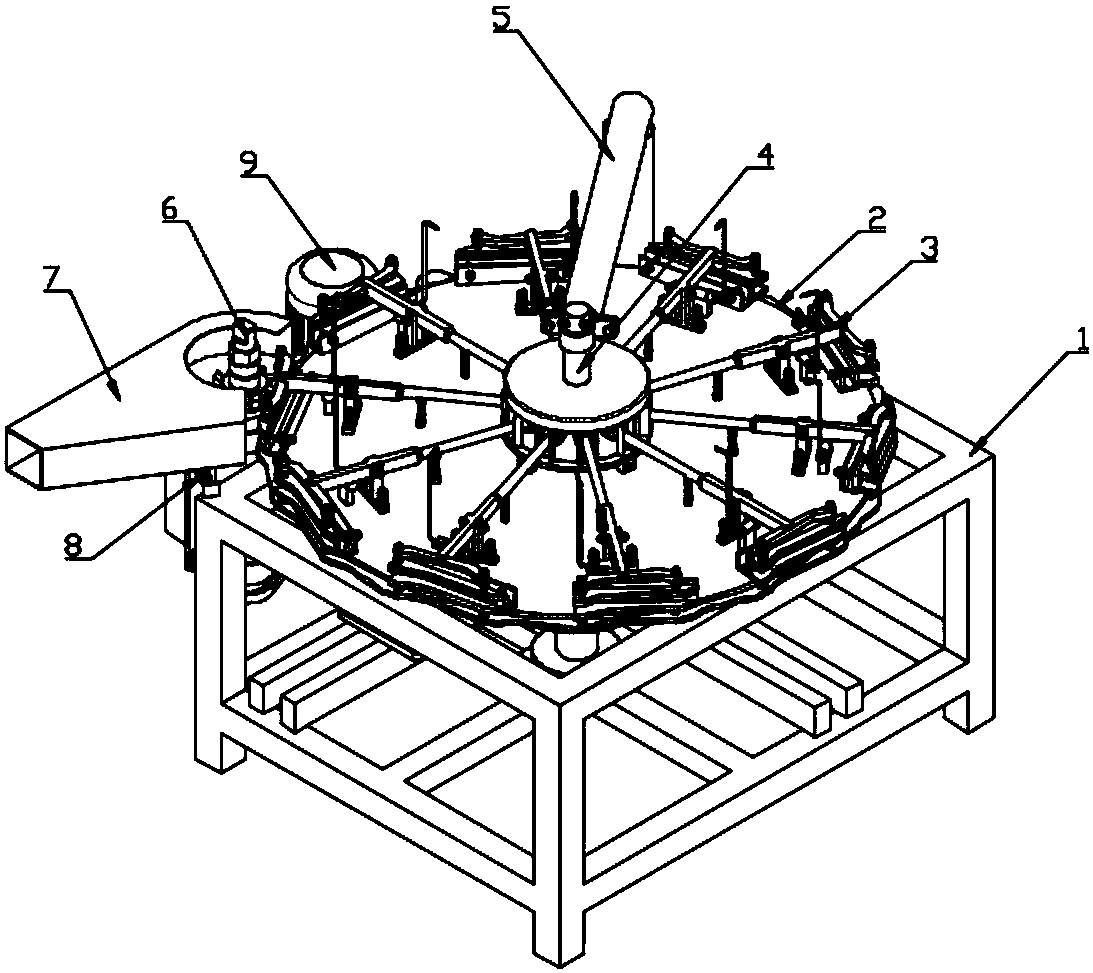

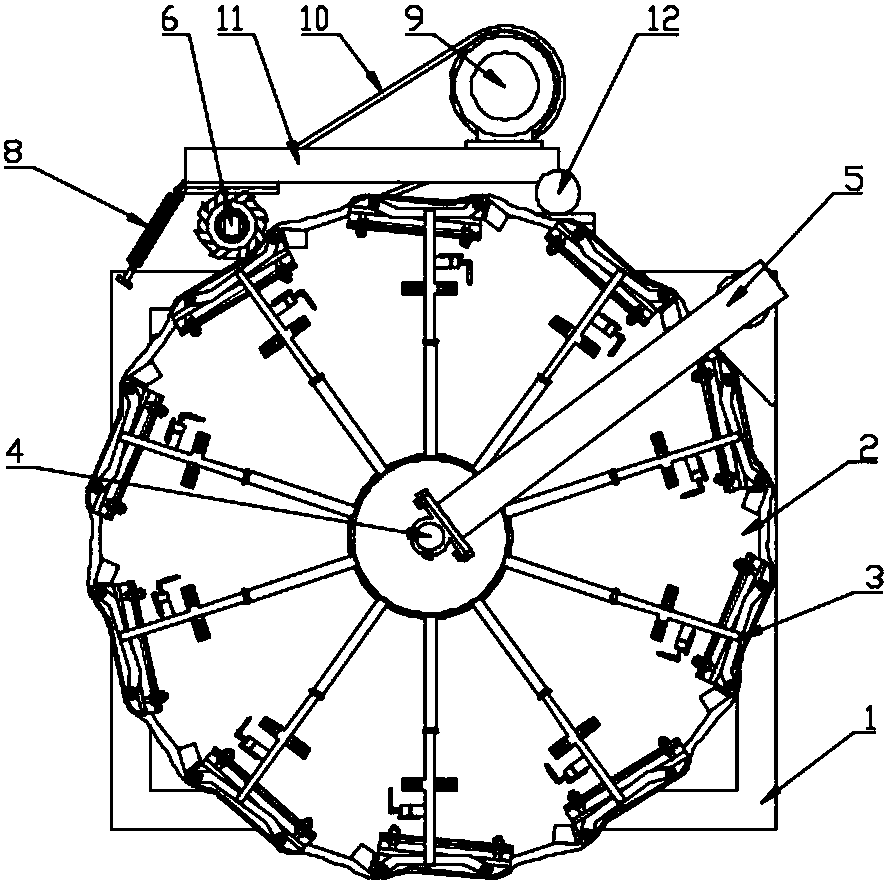

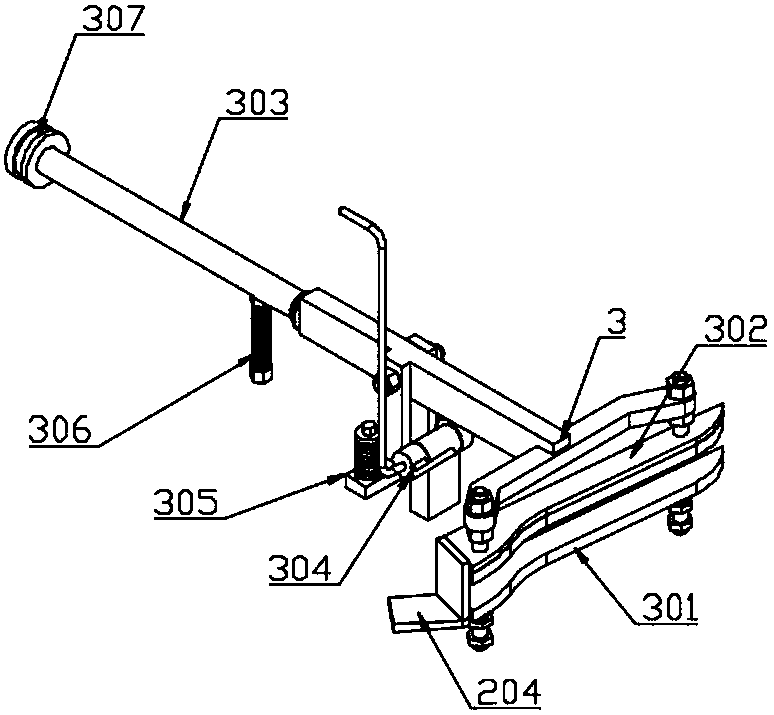

[0032] The present invention is a wooden clothes hanger shape forming processing system, which is to make wooden strip blanks of corresponding lengths, that is, processed parts 18 (the same below), after cutting wooden strips, and then use a forming processing device to process and shape, including wooden clothes hangers. Cutting device, wooden clothes hanger shape cutting device, which specifically is to firstly process the wooden slab blanks of the corresponding length through the double-side...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap