Manufacturing technology and device of PU edge-sealed conveyer belt

A technology of edge banding equipment and conveyor belts, which is applied to belts, other household appliances, household appliances, etc., can solve the problems of waste of raw materials, low production efficiency, waste of working hours, etc., and achieve the effect of reducing working hours and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

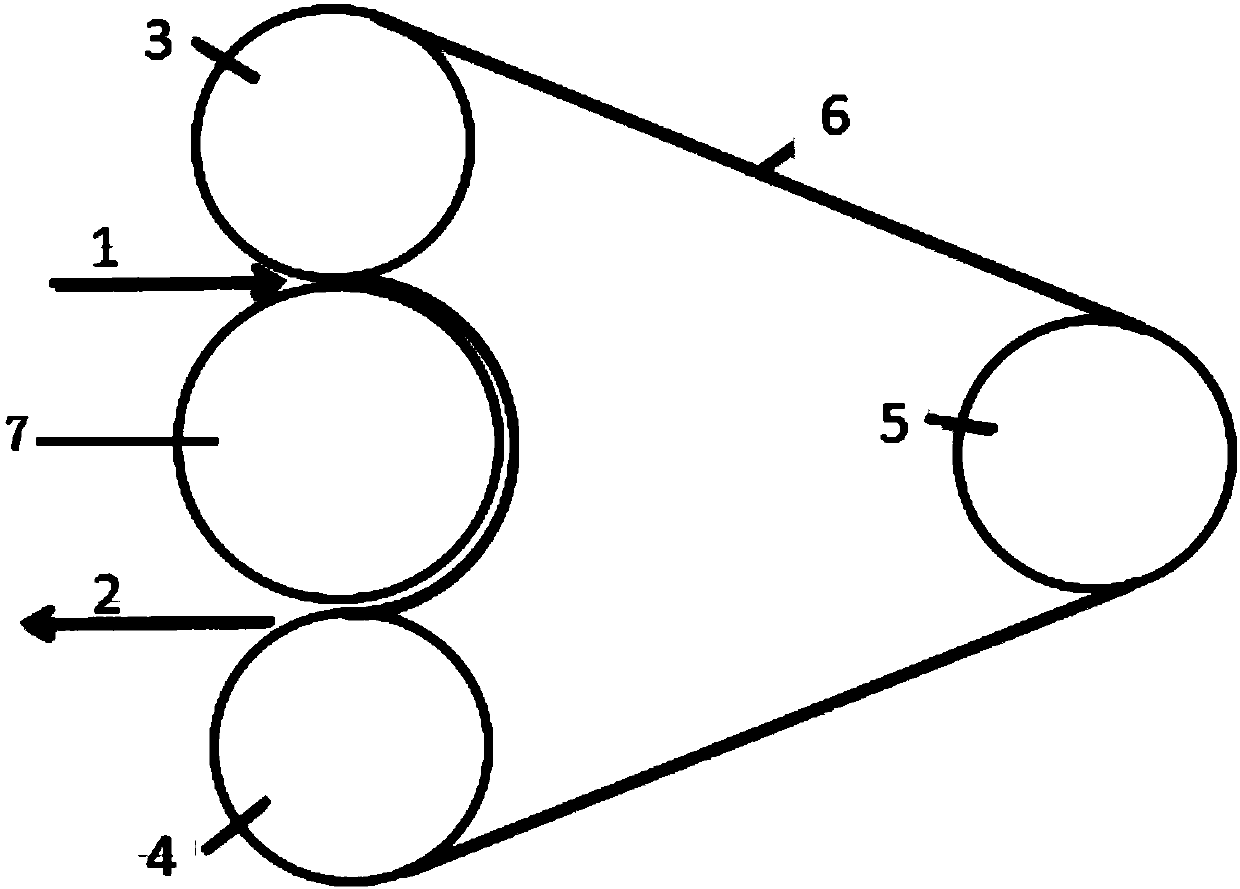

[0020] see figure 1 , a PU edge sealing conveyor belt edge sealing equipment, including the first pressure roller 3, the second pressure roller 4, the main roller 7, at least one guide roller 5; the first pressure roller 3, the second pressure roller 4, at least A guide roller 5 tensions the pressurized steel belt 6, and one of them is a power roller; a main roller 7 is arranged between the first press roller 3 and the second press roller 4, and the fabric guide roller 7 and the steel belt 6 There is a set pre-tightening force between them; the fabric and PU glue enter the edge banding equipment from between the main roller 7 and the first pressure roller 3, and pass from the second pressure roller 4 to the fabric roller 7 under the guidance of the steel belt 6. The space is separated; the width of the PU glue is greater than the width of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com