Double-face heating sealing machine device

A double-sided heating and sealing machine technology, used in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of continuous heating time difference, affecting the overall quality of product packaging, and unsatisfactory sealing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

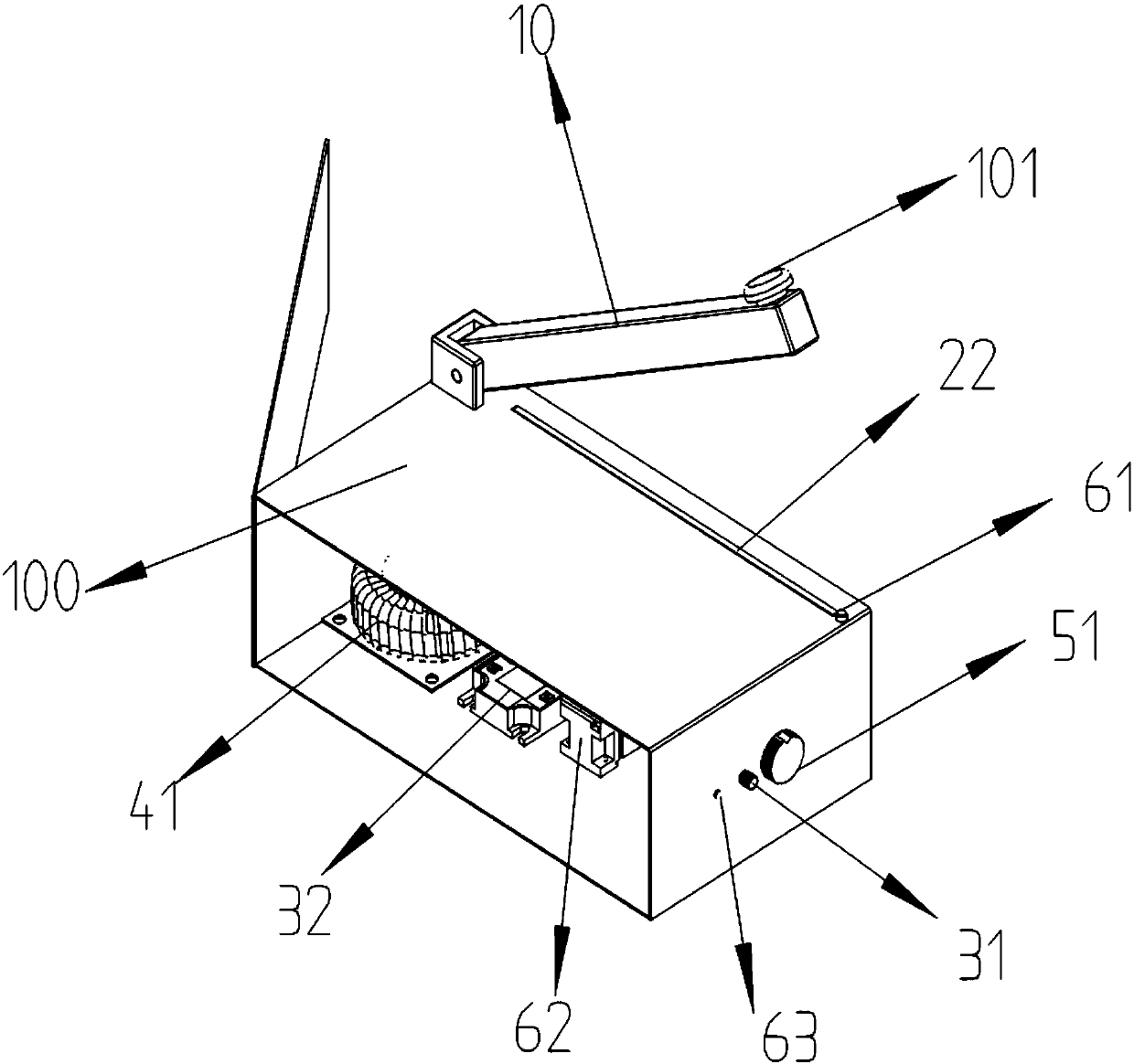

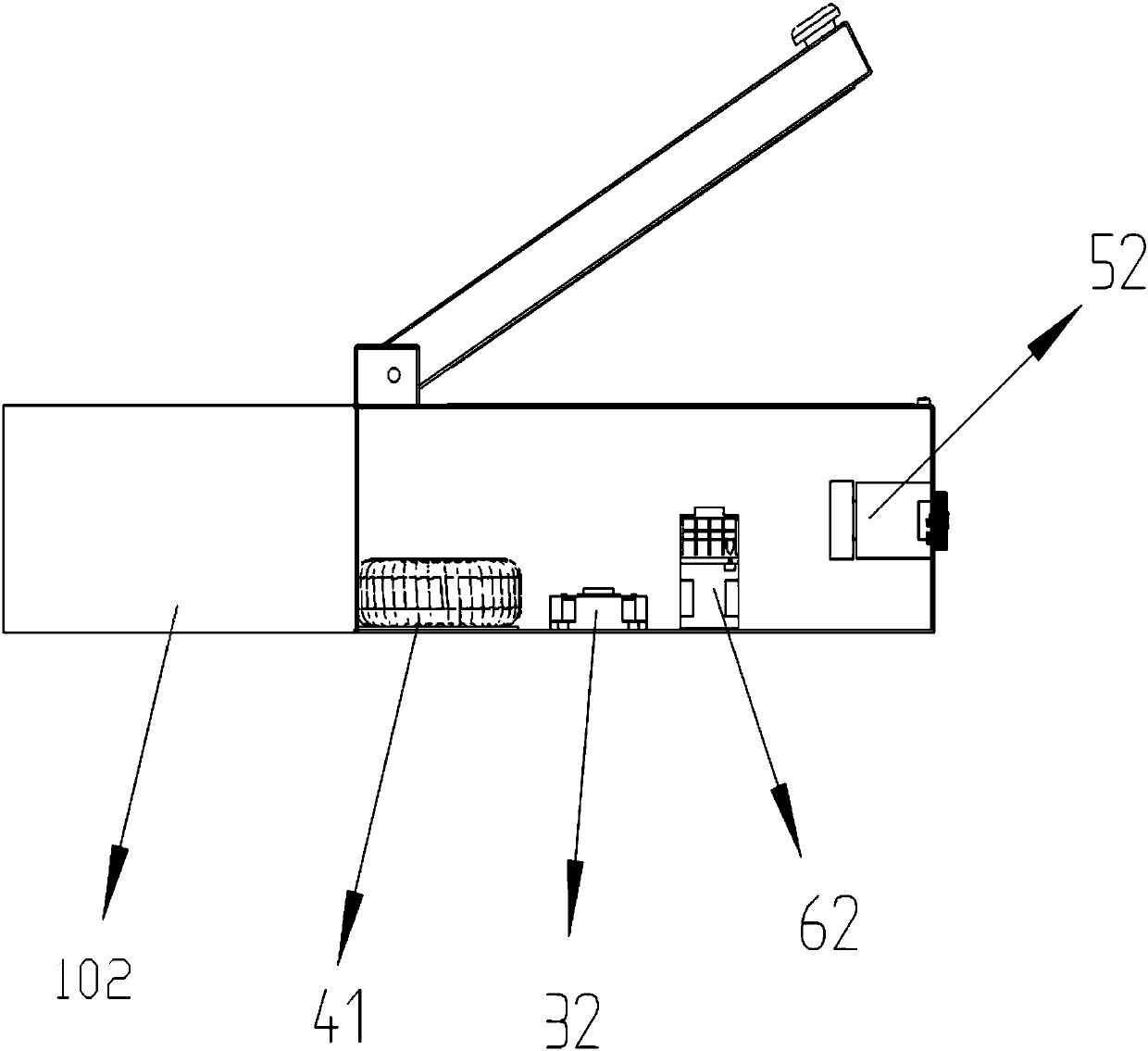

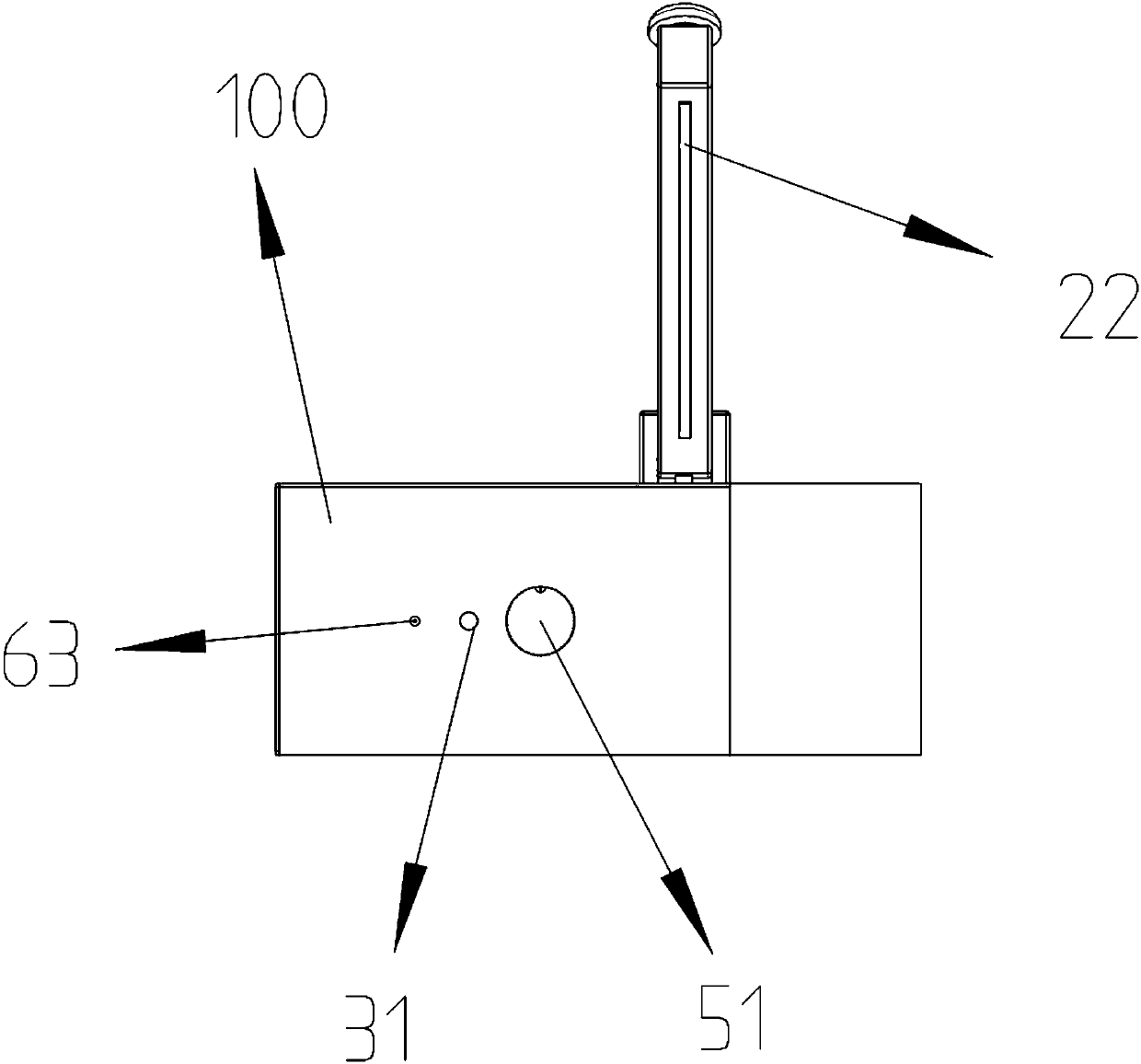

[0033] Such as Figure 1 to Figure 3 As shown, a double-sided heating sealing machine device includes a heat sealing device, a crimping device, a heating power output module, a voltage regulation module, a switch control module, a time control module, and a housing 100. The housing 100 is a rectangular box and An openable box door 102 is provided. After the box door 102 is fastened, a closed accommodating chamber is formed inside the casing 100 .

[0034] The crimping device consists of an upper pressing arm 10 and a lower pressing arm. The heat sealing device consists of an upper heating belt 21 and a lower heating belt 22. The upper heating belt 21 is embedded in the upper pressing arm 10, and the lower heating belt 22 is embedded in the lower pressing arm. , it can also be directly set as only the upper pressing arm 10, and the lower heating belt 22 is embedded in the surface of the housing 100 that can be attached to the upper pressing arm 10 as desired. The upper pressin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com