Method for forging and pressing heel of AT steel rail

A rail and rail bottom technology, applied in forging/pressing/hammer devices, forging/pressing/hammering machinery, manufacturing tools, etc., can solve problems such as low production efficiency, reduced train operation comfort, and misalignment of rail bottom centerlines, etc. problem, to achieve the effects of short heating transition section, scientific heating rate, and uniform distribution of temperature field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

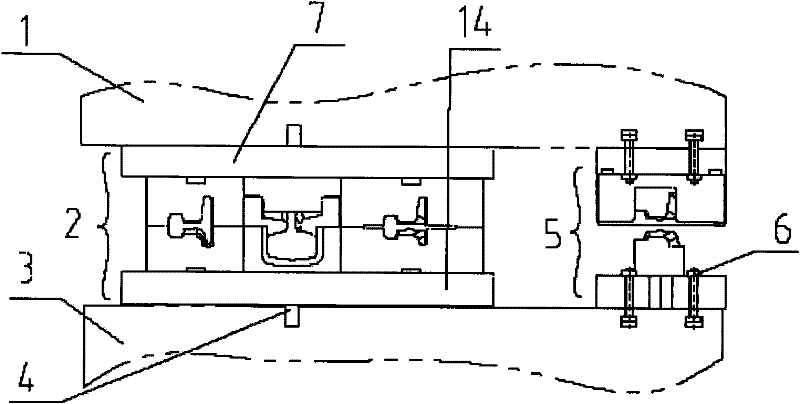

[0039] see figure 1 In the method of the present invention, the AT rail heel end hot-die forging forming die includes a three-station forming die 2 and a one-station trimming die 5; the three-station forming die 2 and a one-station trimming die 5 are on the press table The three-station forming mold 2 is positioned and connected with the lower worktable 3 of the press through the flat key 4; the one-station trimming mold 5 is connected to the upper sliding block 1 of the press through the serial number 3 high-strength bolt 6 respectively. The lower workbench 3 is connected.

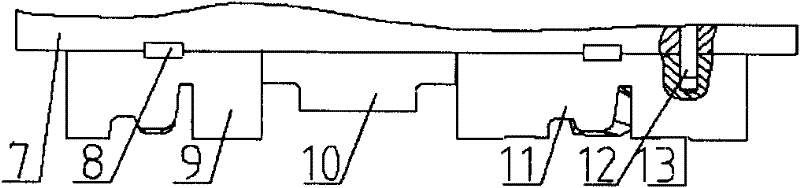

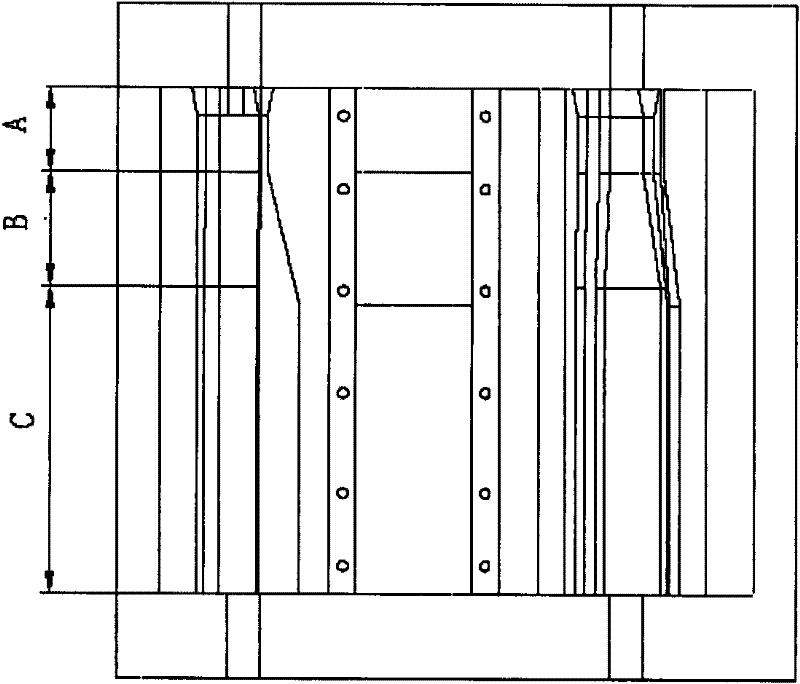

[0040] see Figure 1 to Figure 9 The three-station forming mold 2 includes an upper mold and a lower mold. The upper mold is composed of a first upper template 7, a first to third station upper molds 9, 10, and 11, and the first and third station upper molds 9 and 11 use flat keys 8 and upper template 7 to achieve positioning. The upper molds 9, 10, and 11 of the first to third stations are fixed on the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com