Diffusion vessel gluing bottle limiting device

A technology of limit device and diffuser, which is applied in the direction of capping with auxiliary device, sealing parts with unloading device, packaging, etc., can solve the problems of low test efficiency, uneven painting, time-consuming and labor-intensive, etc., and achieve test Fast efficiency, high application efficiency, and labor-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

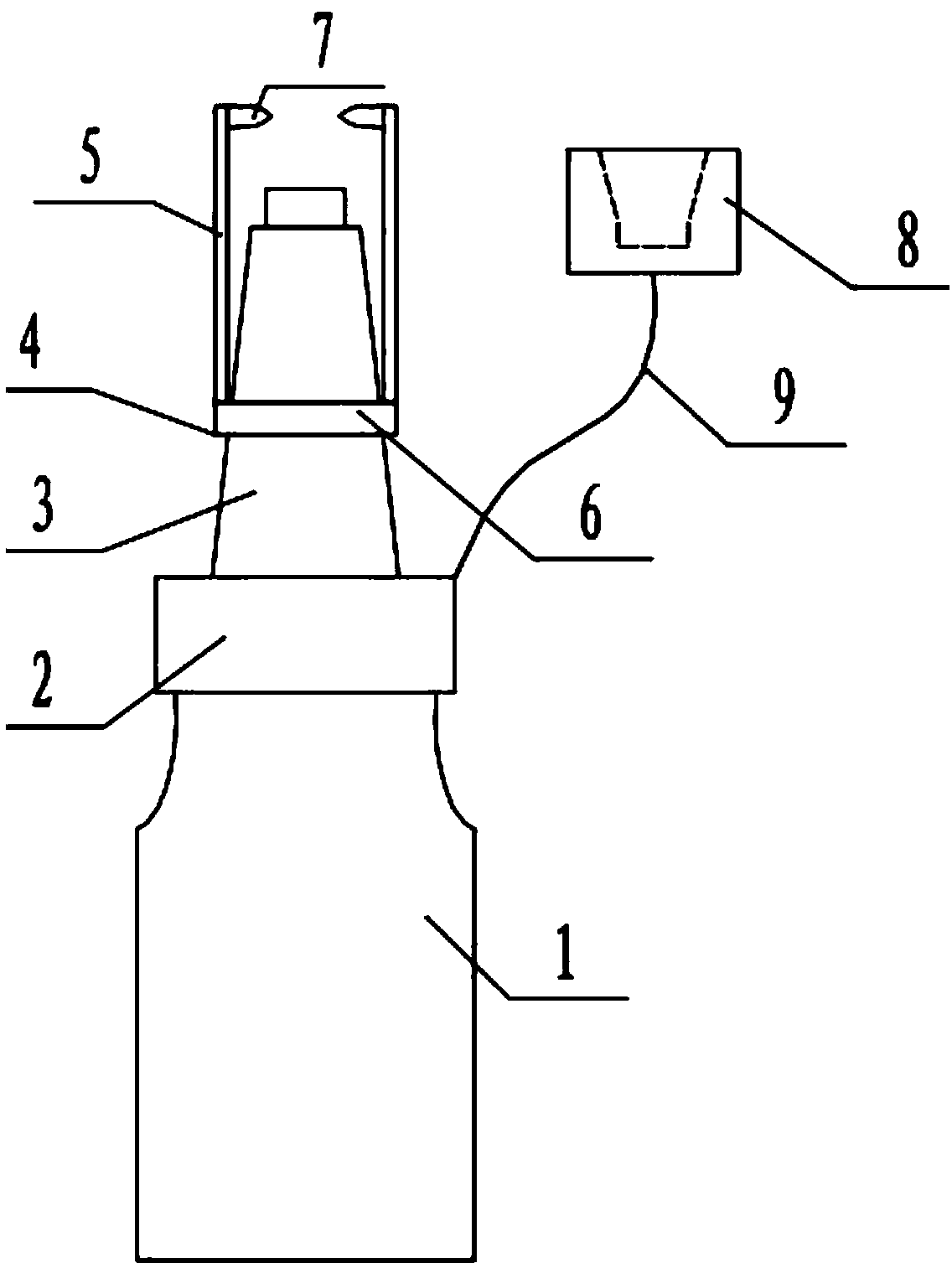

[0012] Embodiment 1: as figure 1 As shown in the figure, a limiting device for a glue-coating bottle of a diffusion dish includes a tapered applicator nozzle 3 arranged on the upper end of the bottle cap 2, the diameter of the end of the applicator nozzle 3 is equal to the thickness of the side wall of the diffusion dish, and a limit clamp is arranged on the applicator nozzle 3 4. The limiting clip 4 is two symmetrical elastic clamping pieces 5 fixed on the collar 6, and the inner ends of the two clamping pieces 5 are provided with limiting protrusions 7, and the distance between the inner ends of the two limiting protrusions 7 is less than The thickness of the side wall of the diffusion dish is 0.2-0.5mm, and the limit structure can closely contact the side wall of the diffusion dish, which greatly improves the application efficiency, the test efficiency is faster, the application is more uniform, and the operation is more time-saving and labor-saving. Point contact, friction ...

Embodiment 2

[0015] Embodiment 2: as figure 1 Shown, a kind of diffusion dish gluing bottle, this gluing bottle comprises the bottle body 1 of elastic plastic system and the bottle cap 2 that cover box is on the bottle body 1 upper end, and the bottle cap 2 upper end is provided with the conical smear mouth 3, smears The end of the nozzle 3 is provided with a liquid-permeable hole, and the bottle body and the applicator nozzle are made by extruding elastic plastic for smearing, which simplifies the operation, greatly saves time, improves the experimental efficiency, and the equipment and materials are cheap.

[0016] Preferably, the above-mentioned bottle cap 2 is threadedly connected to the bottle mouth of the bottle body 1, which is convenient for loading and unloading, and easy for liquid filling.

[0017] Preferably, the end of the above-mentioned applicator mouth 3 is provided with a sealing cap 8 to prevent the volatilization of the glue, and the sealing cap 8 is connected to the bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com