Small mechanical cantilever crane capable of rotating and transversely moving

A cantilever crane, small-scale technology, applied in the direction of cranes, etc., can solve the problems that affect the work progress and cycle, the crane cannot meet the requirements, and occupy the resources of lifting machinery, so as to improve work efficiency, promote the use value, and have a simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

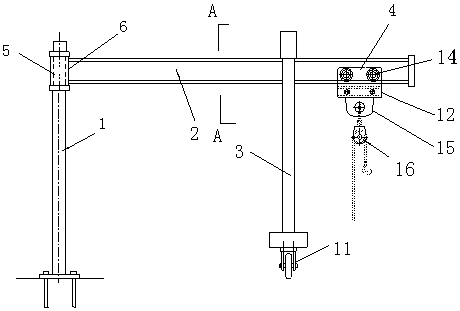

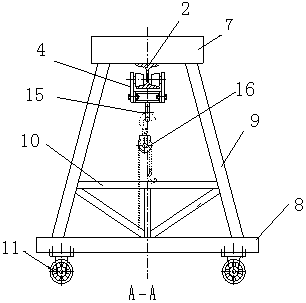

[0017] The present invention is made up of supporting column 1, rotating beam 2, walking support 3, hoisting mechanism 4 four parts.

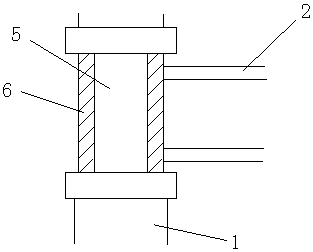

[0018] As shown in the figure, the support column 1 is placed vertically, and the lower end of the support column 1 is fixedly connected to the foundation through anchor bolts. The upper end of the supporting column 1 has a vertical rotating shaft 5, and a rotating shaft sleeve 6 is installed outside the rotating shaft 5. The rotating shaft sleeve 6 can rotate around the rotating shaft 5. The outer wall of the rotating shaft sleeve 6 is welded to one end of the horizontal rotating beam 2. , the rotating beam 2 can rotate around the support column 1 within a range of 360 degrees through the rotating shaft 5 and the rotating sleeve 6 . Rotating shaft sleeve 6 and rotating shaft 5 can adopt copper sleeve to cooperate, also can adopt bearing to cooperate, and its structure is mature technology, repeats no more.

[0019] As shown in the figure, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com