Winch automatic controlling type three-section folding conveyor

A hoist and conveyor technology is applied in the field of three-section folding conveyors, which can solve the problems of high cost, large belt negative allowance, and self-heavy weight, and achieve the effects of convenient operation, reduced self-weight, and reduced production and manufacturing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

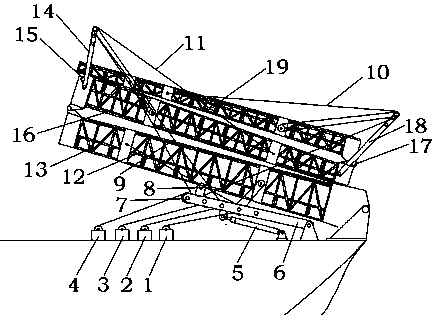

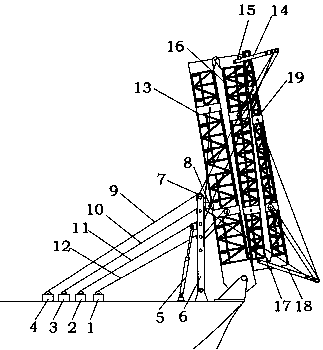

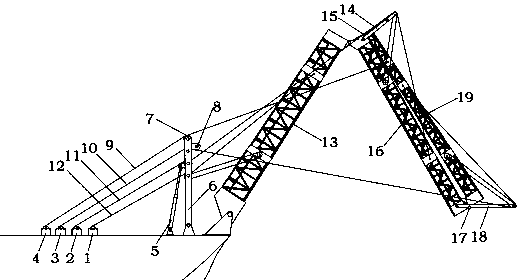

[0025] Such as figure 1 As shown, a three-section folding conveyor automatically controlled by a hoist, including a three-section conveying arm, a main gantry 6, and a hoist; it is characterized in that it also includes an auxiliary gantry I14, an auxiliary gantry II18, a hydraulic cylinder 5, and a limit device I15 , limit device II 17, steel wire rope; the first conveying arm 13 adopts a trapezoidal truss structure, its large end is hinged with the base installed on the hull, its small end is hinged with the second conveying arm 16 large end, and the connection is located at Below the first delivery arm 13 and the second delivery arm 16; the big end of the third delivery arm 19 is hinged with the small end of the second delivery arm 16, and the joint is located at the second delivery arm 16 and the third delivery arm 19 above; the auxiliary gantry I1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com