Horizontal well AICD intelligent water controlling sieve tube performance testing system

A test system and technology for horizontal wells, which are used in wellbore/well components, wellbore/well valve devices, and production fluids, etc., can solve problems such as the inability to test oil stabilization and water control performance parameters, and achieve good supply and pressure stability. and fluid adaptability, flexible and convenient adjustment, and safe operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

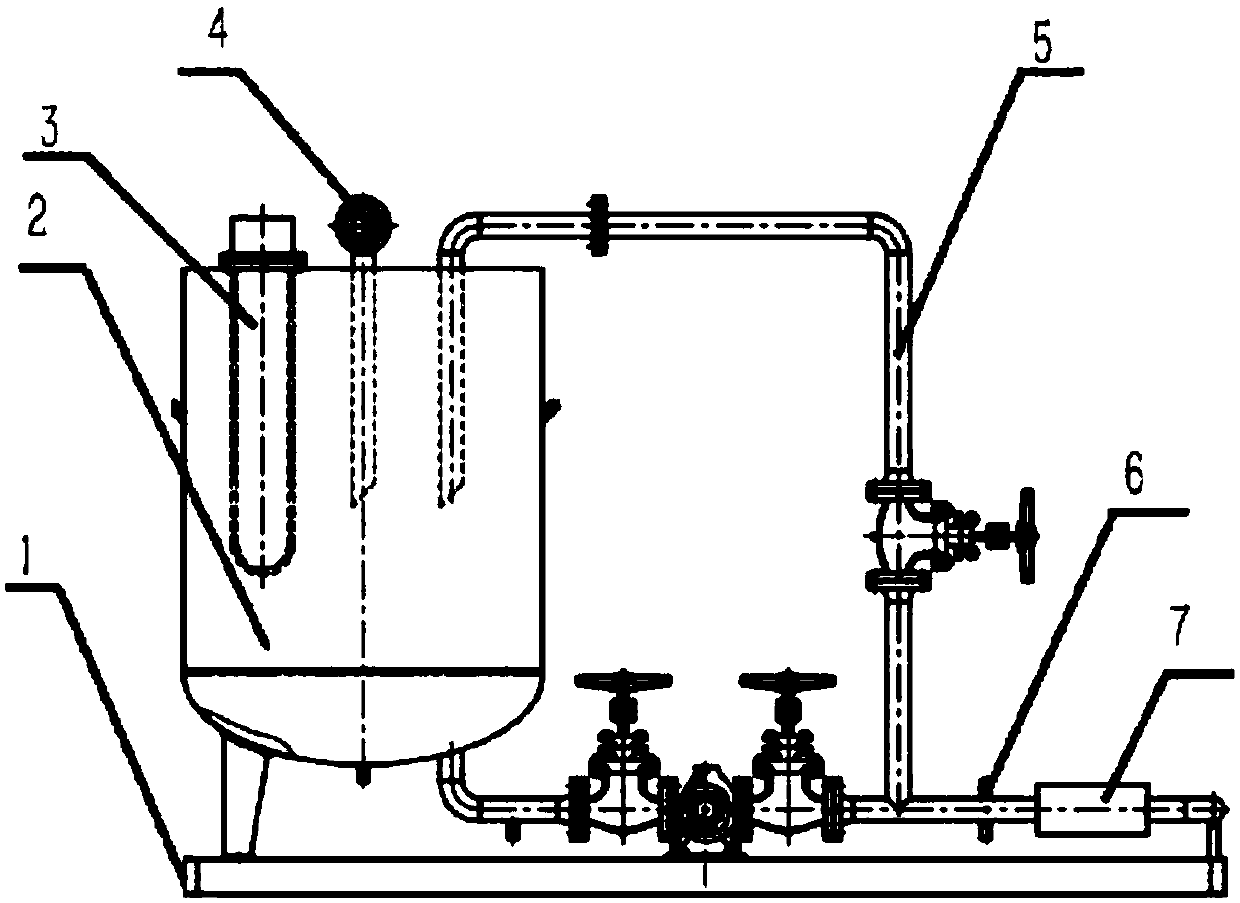

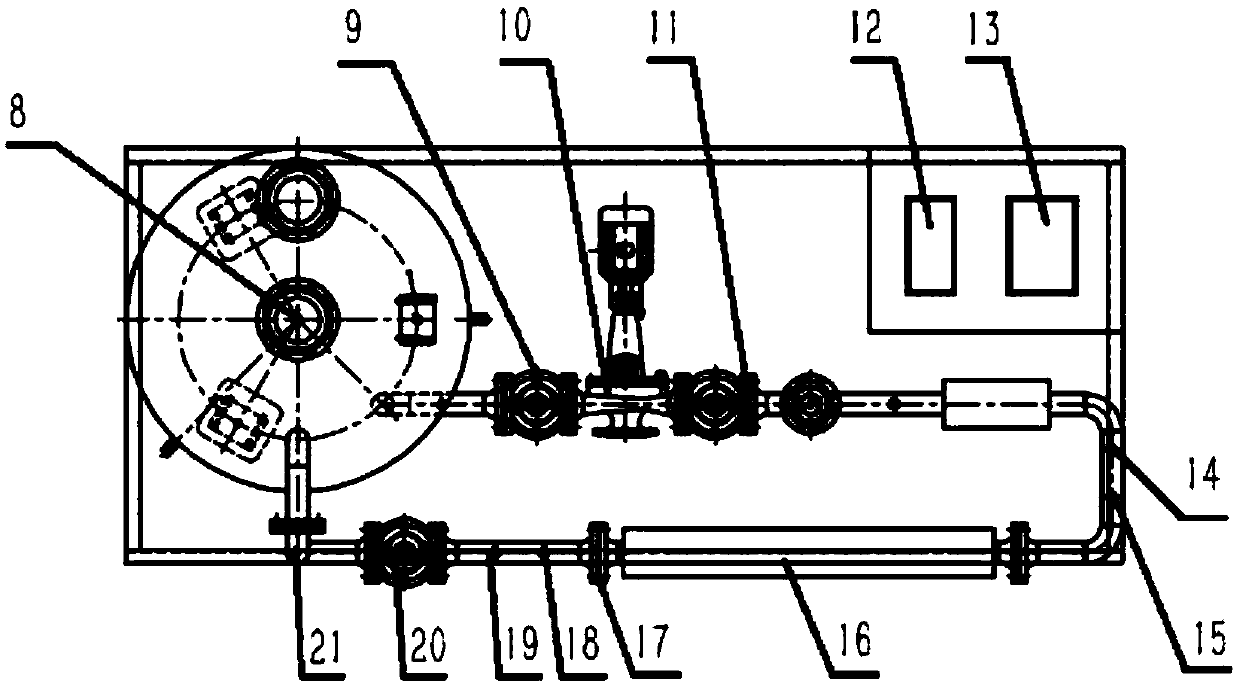

[0020] refer to figure 1 and figure 2 Embodiments of the present invention are further described:

[0021] The pipeline with inlet pressure gauge 15, inlet flowmeter 7 and safety valve 14 is connected to the outlet flange of the high-pressure plunger pump through the flange joint 11, and the other end of the flange joint is connected to the AICD intelligent water control screen 16 through the flange , the outlet of the AICD intelligent water control screen is connected to the outlet pressure gauge 15, the inside of the AICD intelligent water control screen is installed with a fixed test AICD intelligent water control valve, and the outlet of the AICD intelligent water control screen is connected to the gate valve 20 and the outlet pipe through the flange joint 17 Road 4, an outlet flowmeter 21 is installed on the outlet pipeline 4, and a pressure relief bypass pipeline 5 is provided at the front end of the AICD intelligent water control screen, and all devices are supported ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com