Through-casing formation resistivity continuous measurement method

A technology of formation resistivity and measurement method, which is applied in the directions of measurement, earthwork drilling, wellbore/well components, etc., can solve the problems of inability to obtain formation resistivity curve, difficulty, low logging time efficiency, etc. Continuous measurement, overcoming the effect of poor safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

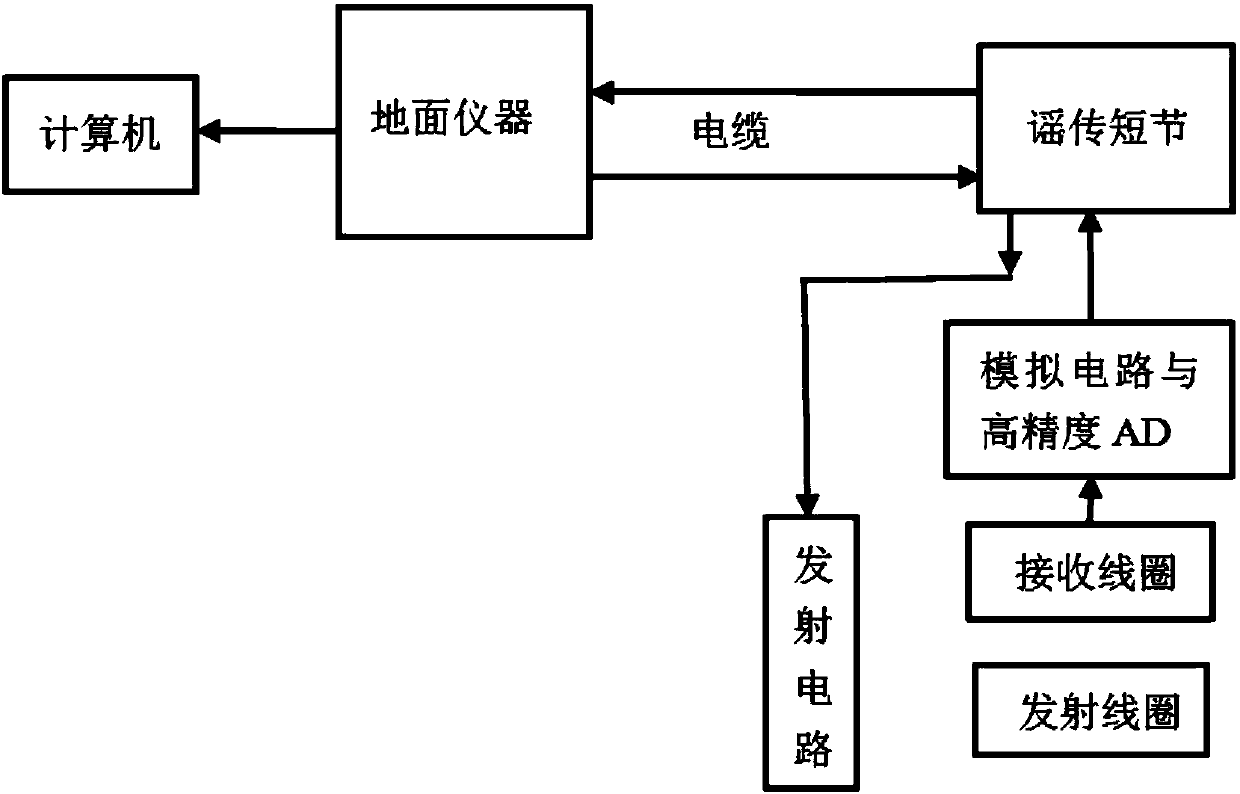

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

[0023] Based on the principle of electromagnetic induction, the present invention excites the transient electromagnetic induction response in the cased well, and the response includes the electromagnetic induction signal caused by the eddy current of the measured formation after propagating through the casing and the formation, and separates the formation eddy current by processing the original logging waveform The electromagnetic induction signal is used to obtain the resistivity of the formation. The method continuously measures in the well, realizes the continuous measurement of the formation resistivity through the casing, and obtains the continuous curve of the formation resistivity. Changing the through-casing resistivity from contact fixed-point measurement to non-contact continuous measurement improves logging timeliness and success rate, facilitating large-sca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com