Object three-dimension surface shape measuring system and method based on fringe projection principle

A three-dimensional surface shape and fringe projection technology, which is applied to measuring devices, instruments, and optical devices, can solve the problems of complex operation and poor portability, and achieve the effects of simple operation, low time cost, and fast measurement speed

Inactive Publication Date: 2018-02-23

UNIV OF ELECTRONIC SCI & TECH OF CHINA

View PDF4 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Therefore, it is urgent to find a method that can solve the poor portability and complicated operation of the current three-dimensional surface measurement system.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0036] In this embodiment, a face mask is taken as an example, and the three-dimensional shape information of the face mask is measured by using the three-dimensional shape measurement system provided by the present invention.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

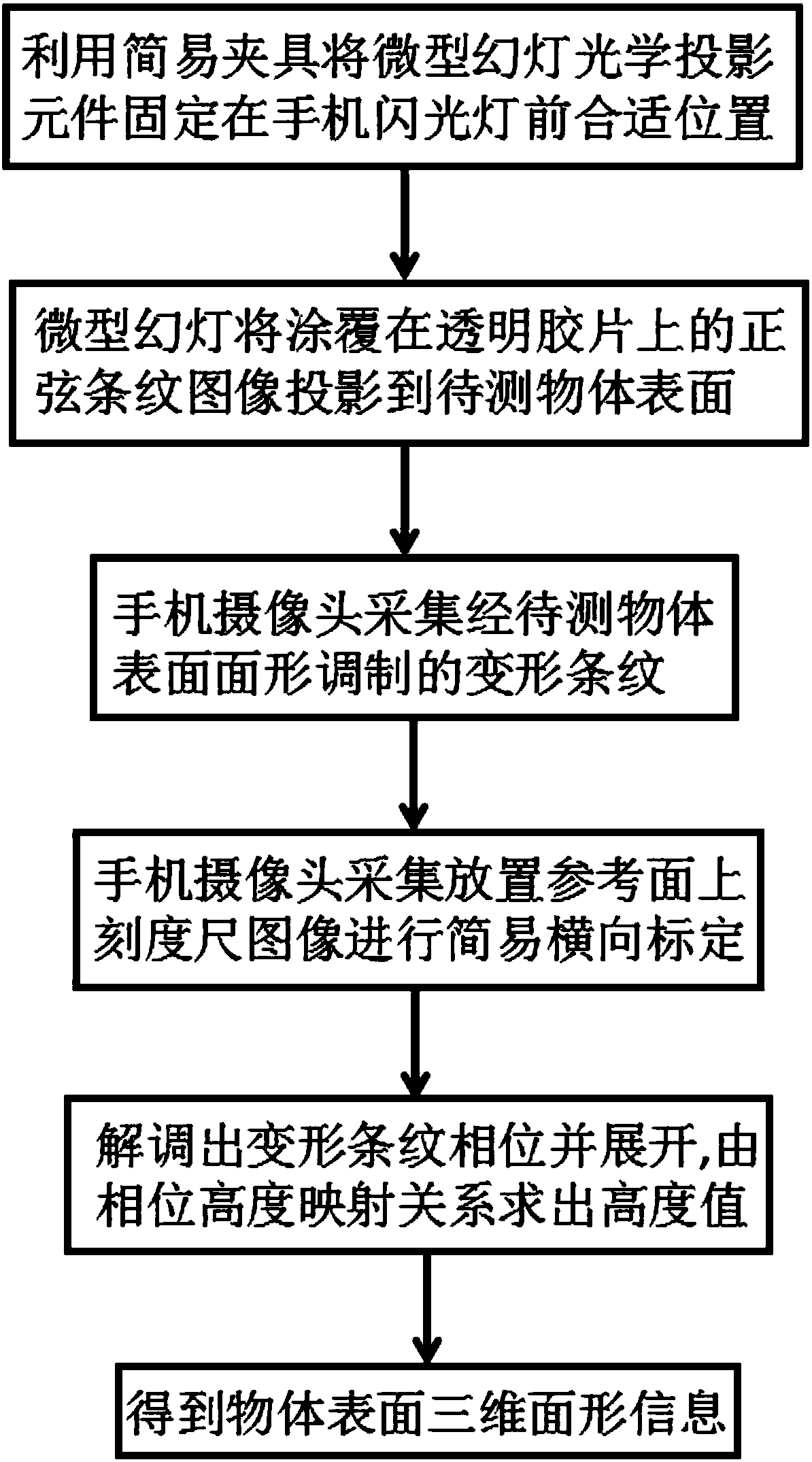

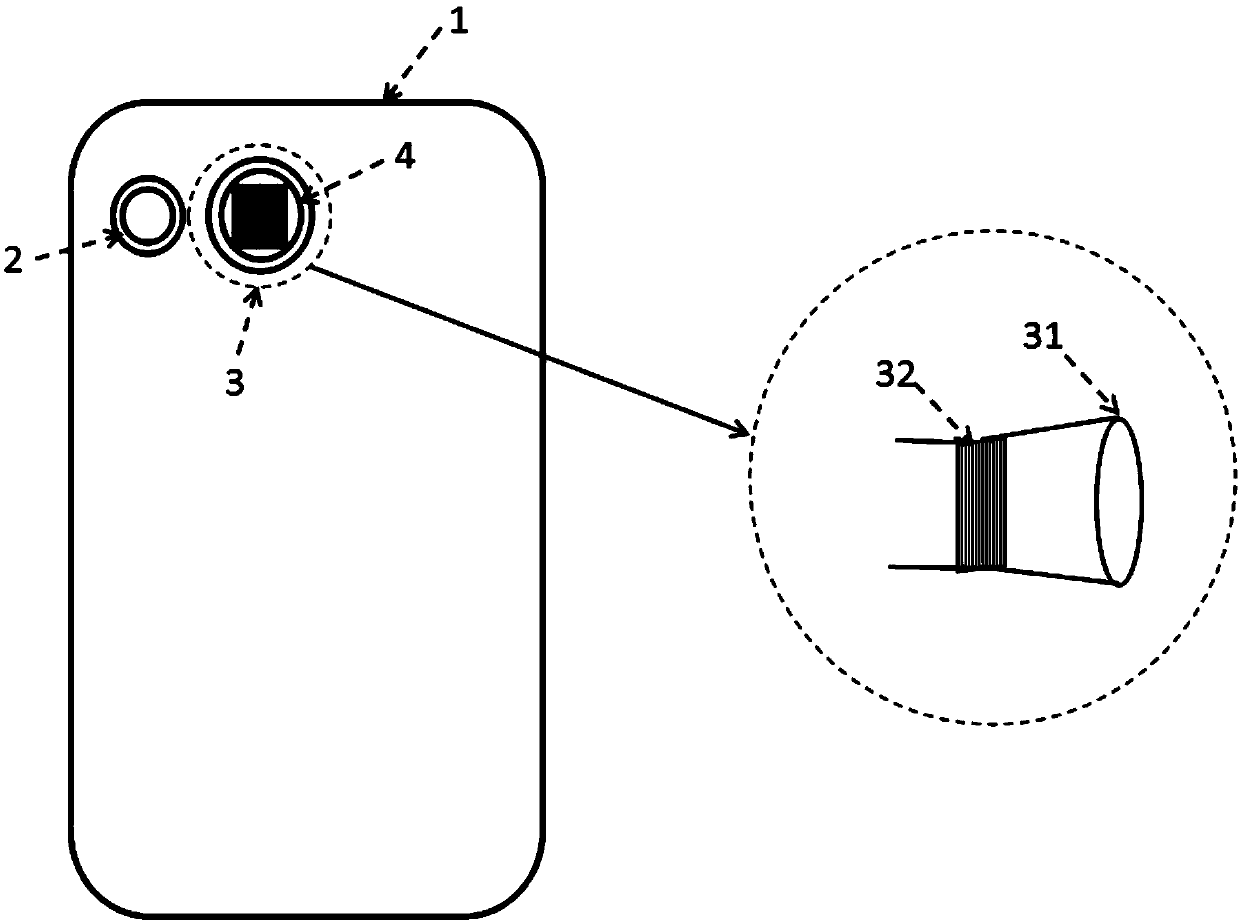

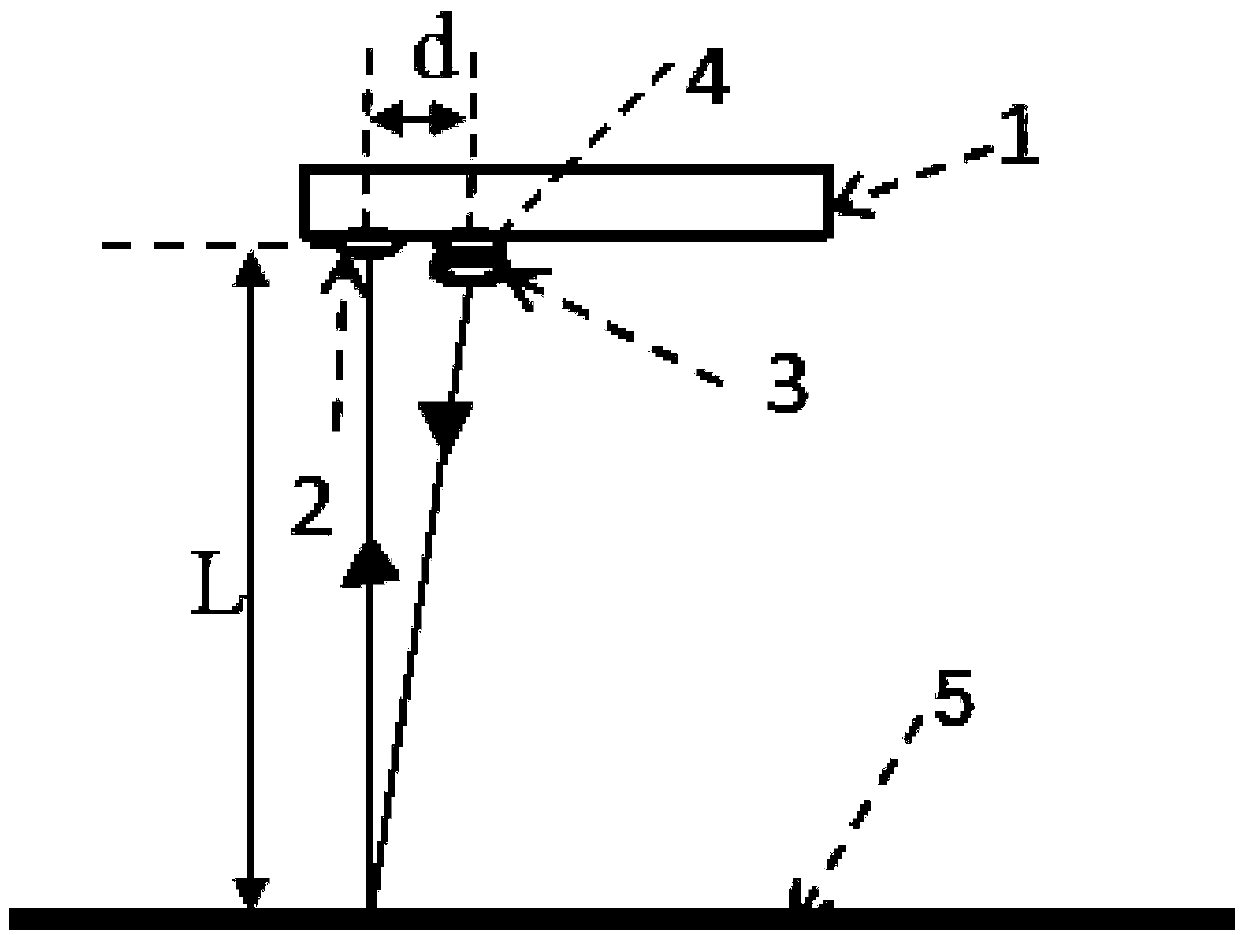

An object three-dimension surface shape measuring system and a method based on a fringe projection principle belong to the object three dimensional measuring technical fields. The method fixes a miniature optical projection element on a mobile phone flash lamp cover, so a sine fringe raster built in the optical projection element can be projected on the surface of a to-be-measured object when theflash lamp is opened; in addition, the intelligent mobile phone can gather deformed fringes obtained by modulating the surface of the to-be-measured object; a data processing module can process the data so as to display the object three dimensional surface shape information on the intelligent mobile phone display screen. Compared with a conventional three-dimension surface shape measuring system based on fringe projection, the measuring system is economical and portable; the measuring method is simple in operation, fast in measuring speed, thus applying the three-dimension surface shape measuring system in daily lives.

Description

technical field [0001] The invention belongs to the technical field of three-dimensional measurement of objects, and in particular relates to a system and method for measuring three-dimensional surface shapes of objects based on the fringe projection principle. Background technique [0002] With the rapid development of precision machining, automobile manufacturing, precision optical processing, semiconductor industry, precision instrument manufacturing, mold design, reverse engineering and other fields, traditional two-dimensional measurement equipment can no longer meet the increasingly modern and automated production requirements. Three-dimensional measurement Technology came into being. At present, the three-dimensional surface measurement of objects mainly includes contact three-coordinate measuring instrument, optical scanning, interferometer and so on. However, the measurement time of the contact three-coordinate machine is quite long (usually more than several hours...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01B11/24

CPCG01B11/2433

Inventor 刘丹佶岳慧敏潘志鹏吴雨祥

Owner UNIV OF ELECTRONIC SCI & TECH OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com