Topological optimization design method for generating bracing structure in additive manufacturing

A support structure and additive manufacturing technology, applied in the field of topology optimization design of support structure generation in additive manufacturing, can solve the problems that cannot be perfected, objectively provide support structure solutions, do not take into account the differences in deformation and stress, and engineers cannot Issues such as support form are given to achieve the effect of reducing the risk of manufacturing failure, reducing cost expenditure, and reducing the risk of deformation and cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to better illustrate the purpose of the invention and its own advantages of the method, further detailed description will be given below with the help of drawings and examples. It needs to be stated here that this example is only used to illustrate the present invention, not to limit the present invention. The type and format of the model, the materials and manufacturing equipment parameters that need to be given, and which topology method is used to generate the support structure can all be freely selected and combined according to different actual problems.

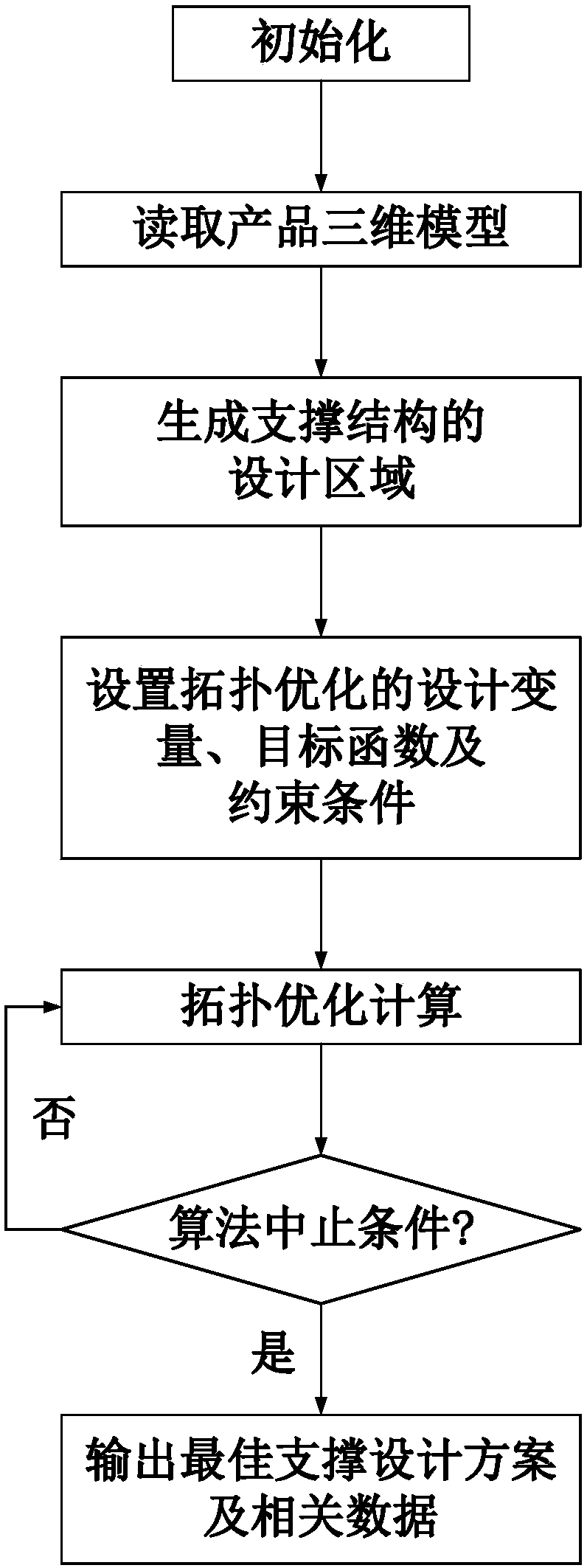

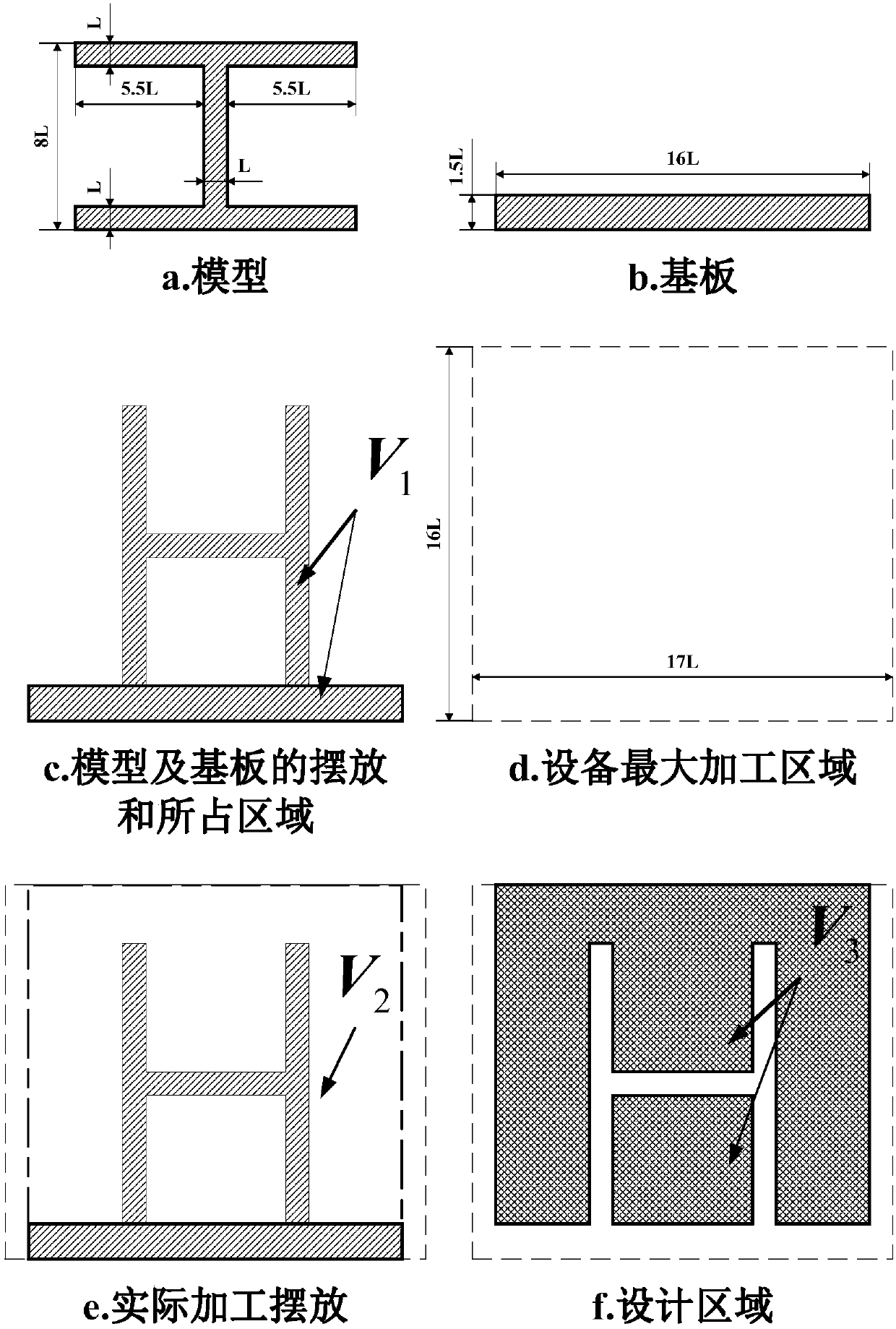

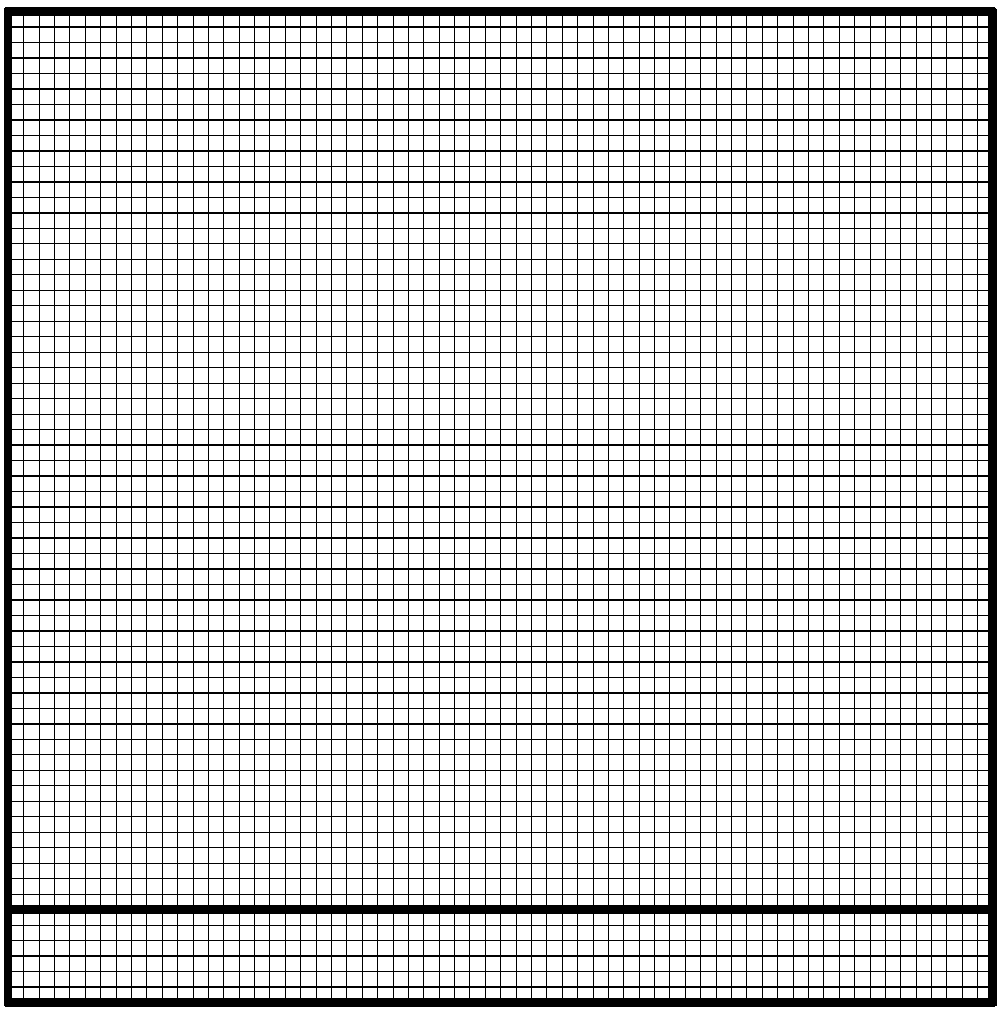

[0023] refer to figure 1 , a topology optimization design method for the generation of support structures in additive manufacturing. The technical scheme is as follows: Step 1: Read the 3D model of the product to obtain information such as its geometric structure; Step 2: Set the The parameters of product placement, substrate and manufacturing equipment, and then generate the design area of the suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com