Ka-band complete-polarization ultrathin frequency selective surface and antenna cover

A frequency selective surface, full polarization technology, applied in the direction of antenna, radiation unit cover, electrical components, etc., can solve the problems of difficult to achieve full polarization, poor out-of-band suppression, heavy weight, etc., to achieve good out-of-band suppression performance, Effect of RCS reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

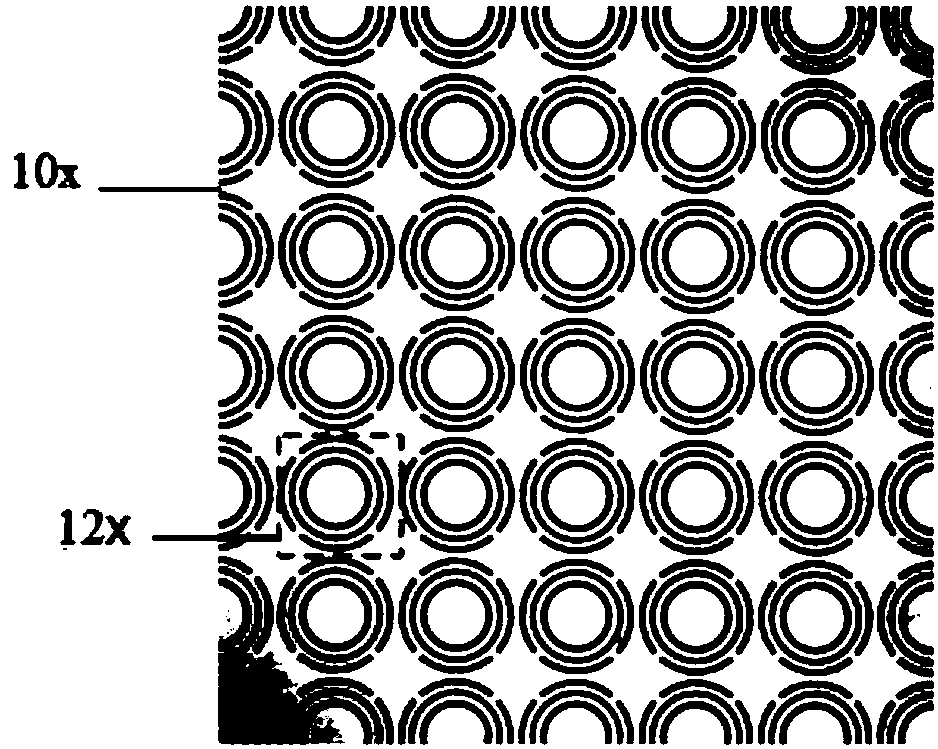

[0036] Such as figure 1 As shown, a Ka-band fully polarized ultra-thin frequency selective surface 10x is provided in this embodiment, comprising a dielectric substrate made of non-conductive material, and metal foil attached to the upper surface and the lower surface of the dielectric substrate layer; the metal foil layer on the upper surface contains several upper periodic micro-unit structures 12x arranged horizontally and vertically periodically, and the metal foil layer on the lower surface contains several lower periodic micro-unit structures 12x arranged horizontally and vertically periodically. Unit structure 13x; the geometric configurations of the upper and lower periodic micro-unit structures are the same; the lower-period micro-unit structure corresponds to the upper-period micro-unit structure.

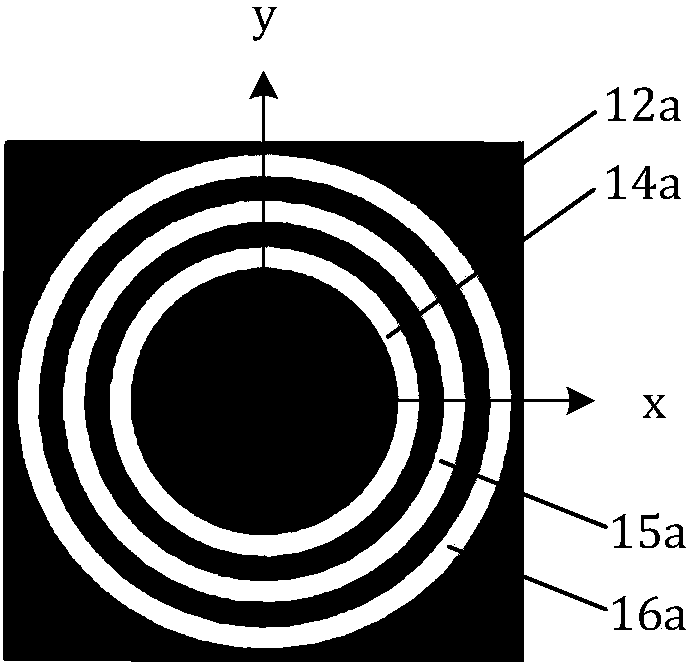

[0037] Such as figure 2 As shown, the micro-unit structure 12x / 13x of the upper / lower period is a square, including three ring-shaped gaps corroded by the circuit board...

Embodiment 2

[0050] This embodiment provides a radome made by using the Ka-band fully polarized ultra-thin frequency selective surface. The frequency selective surface employs as Figure 5 The third unit structure is shown. The side length of the cell structure is 4 mm. The radome includes 625 square unit structures, and its size is 100mm×100mm×0.5mm. The dielectric substrate of the radome adopts the sheet material of Rogers Company, the dielectric constant is 3.66, the loss tangent is 0.004, and the thickness is 0.5 mm.

[0051] Figure 11 Shown is the test platform where the frequency selective surface radome was tested. The test platform includes a flat radome 2, two Ka-band standard horn antennas 31, 32, and a vector network analyzer 4 connected to the antennas. The working frequency bands of the two Ka-band standard horn antennas 31 and 32 are from 26.5 GHz to 40 GHz. Wherein 31 is a transmitting antenna, 32 is a receiving antenna, 31 and 32 are respectively connected with two p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com