Gear motor used for cleaning machine

A technology for geared motors and cleaning machines, applied in the directions of electromechanical devices, electrical components, electric components, etc., can solve the problems of difficult positioning, small bearing capacity, large volume, etc., and achieve the effect of compact structure, convenient connection and improved bearing capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

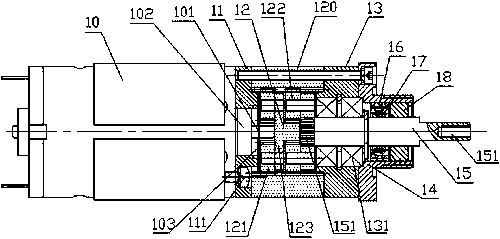

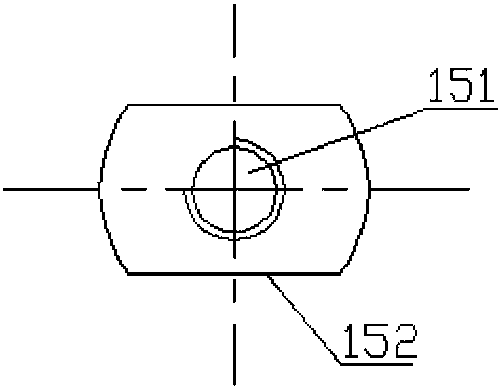

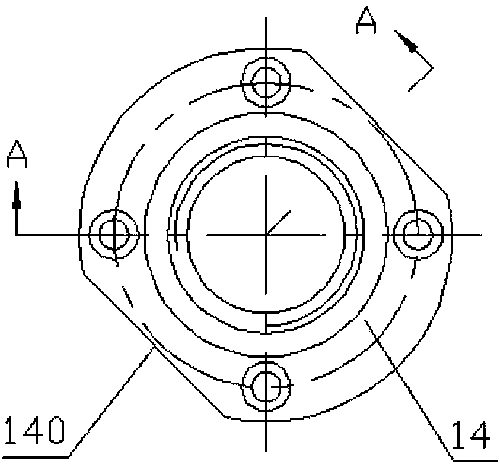

[0019] Such as figure 1 As shown, a deceleration motor for a washing machine includes a motor body 10 and a connecting cover 11, a planetary gear reduction assembly 12, a bearing cover 13, a front cover plate 14 and The output shaft 15 passing through the inner hole of the bearing cover and the inner hole of the front cover plate, the bearing 131 matched with the output shaft 15 is provided in the inner hole of the bearing cover, and the bearing 131 matched with the output shaft 15 is provided in the inner hole of the front cover plate. Sealed structure.

[0020] Wherein, the planetary gear reduction assembly 12 includes a ring gear 120 and a first planetary gear set 121 and a second planetary gear set 122 arranged in the ring gear, and the output end 101 of the motor shaft extends into the center of the ring gear and is installed There is a pinion 103 which meshes with the planetary gears of the first planetary gear set, and the input end of the output shaft is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com