A high voltage and high power igbt drive circuit

A driving circuit and high-power technology, applied in the field of power electronics, can solve the problems of pulse width limitation omission, damage to IGBT tubes, etc., and achieve the effects of low cost, small delay jitter, and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the contents mentioned in the embodiments are not intended to limit the present invention.

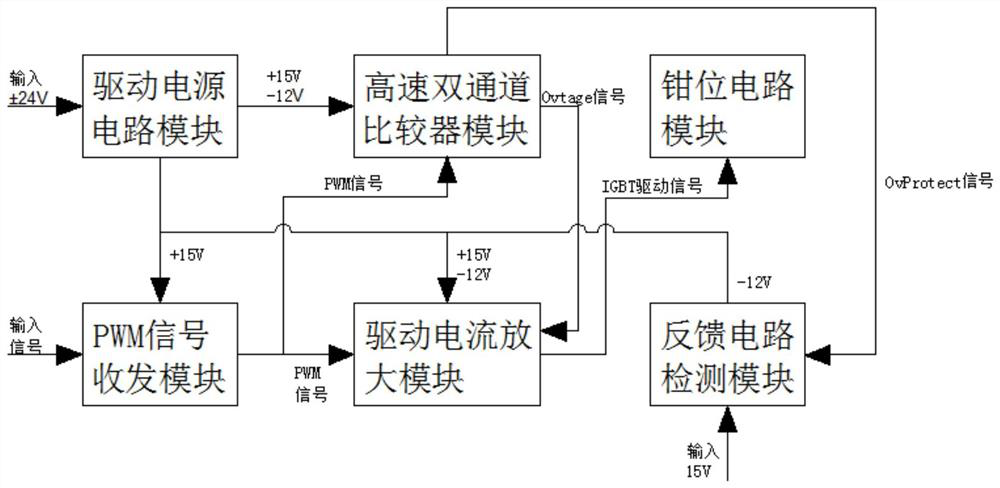

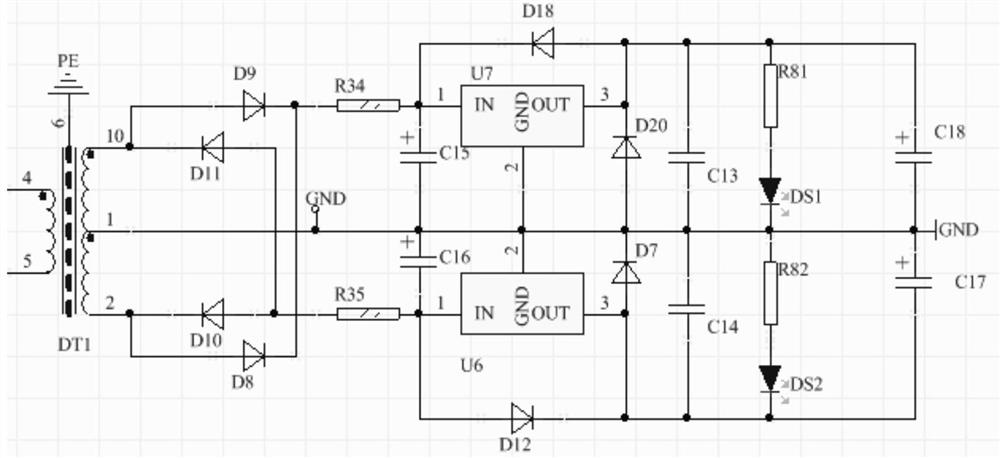

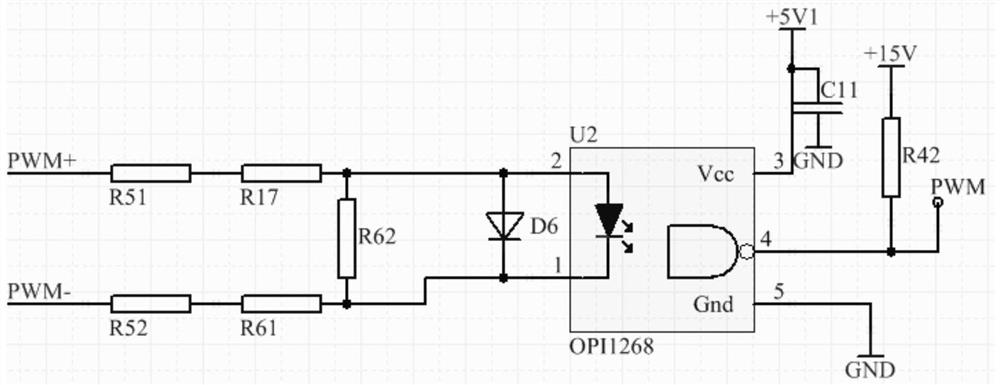

[0035] refer to figure 1 As shown, a high-voltage high-power IGBT driving circuit of the present invention includes: a driving power circuit module, a PWM signal transceiver module, a high-speed dual-channel comparator module, a driving current amplification module, a feedback circuit detection module, and a clamping circuit module; The power supply circuit module provides the required power for each module; the signals of the PWM signal transceiver module and the high-speed dual-channel comparator module are connected to the driving current amplification module, the signal generated by the driving current amplification module drives the IGBT, and the feedback circuit detection module is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com