Constant temperature control device of microwave synthesizer

A technology of constant temperature control and synthesizer, applied in electric heating devices, microwave heating, chemical instruments and methods, etc., can solve the problems of slow reaction speed, limited cavity volume, high temperature control requirements, etc., and achieve uniform and stable microwave temperature. , the effect of improving the response effect and improving the work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

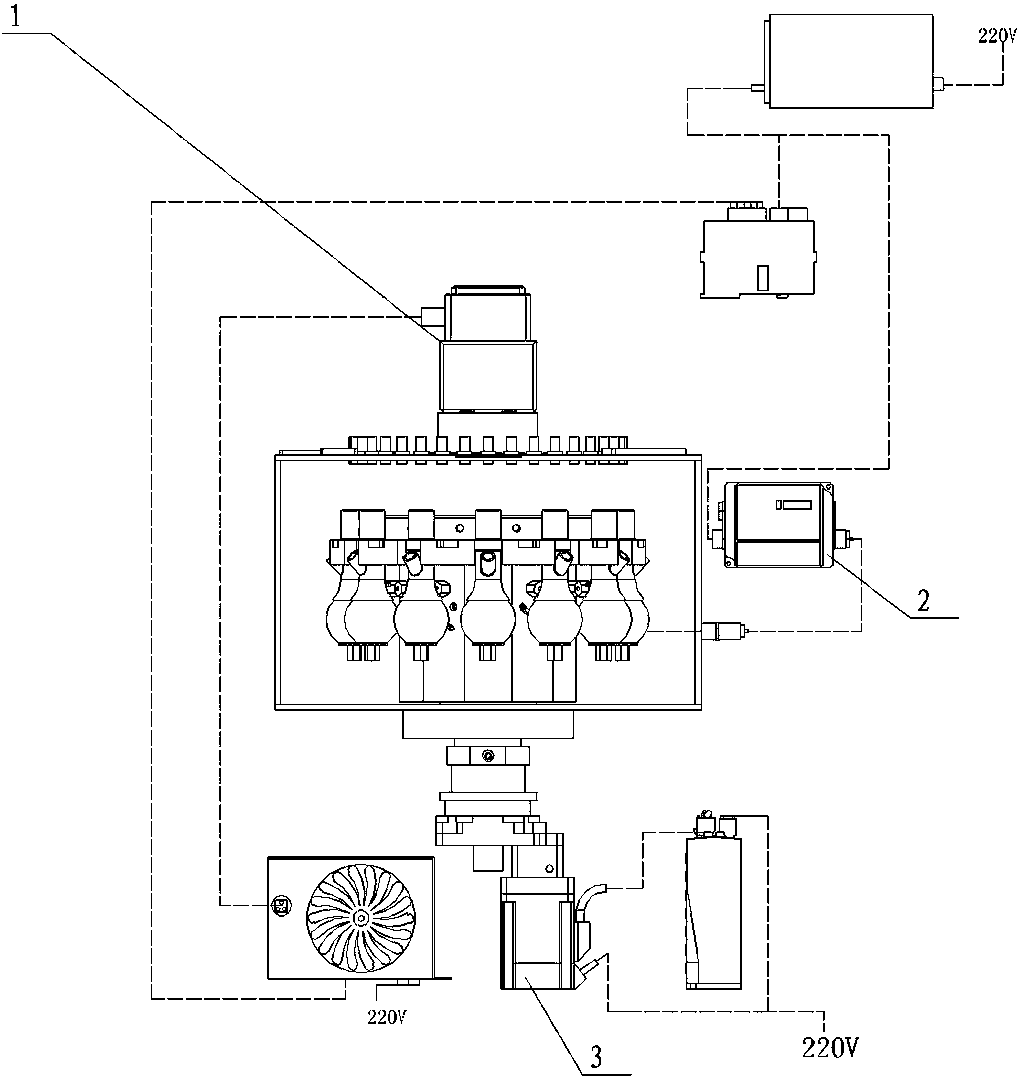

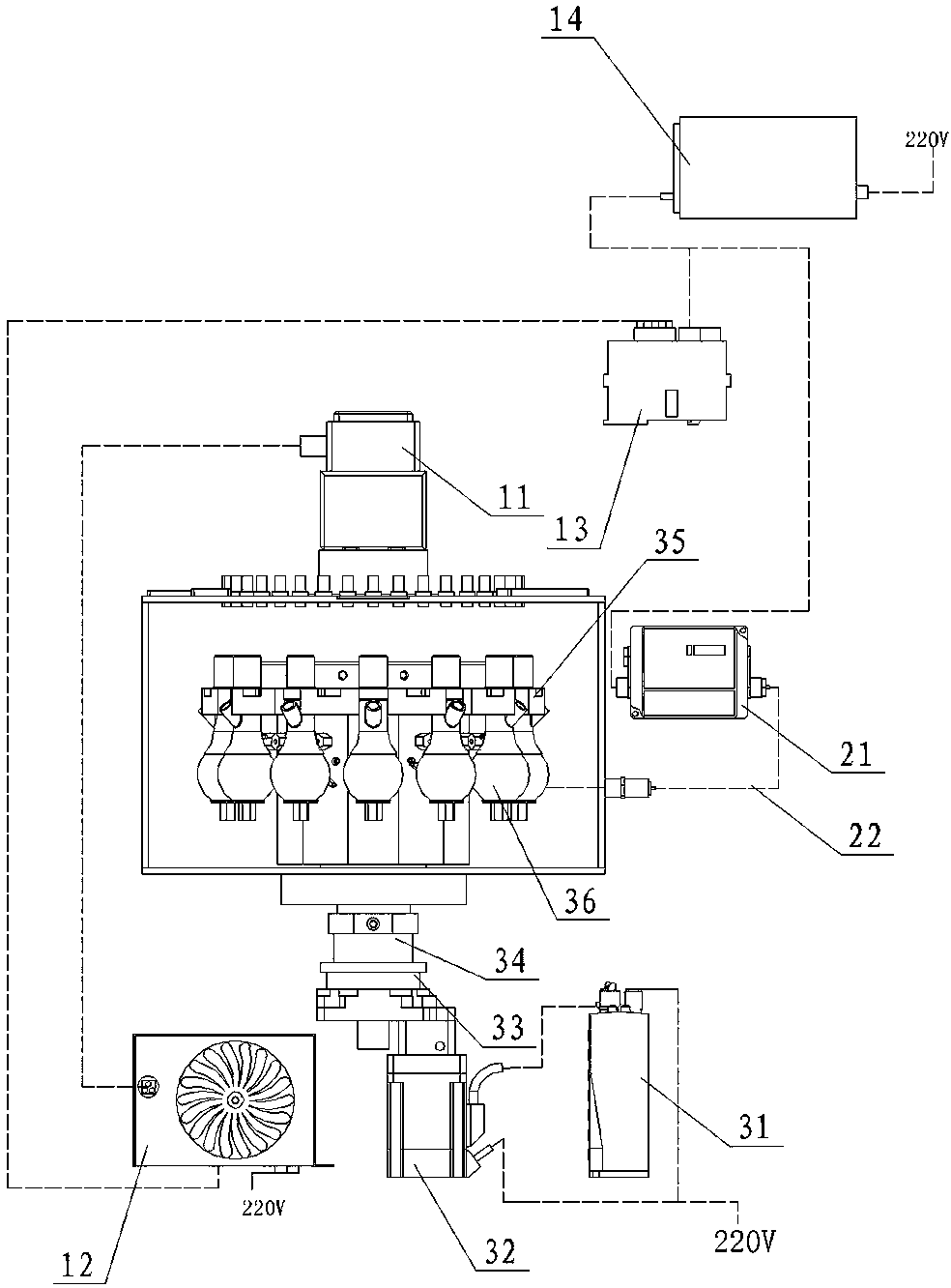

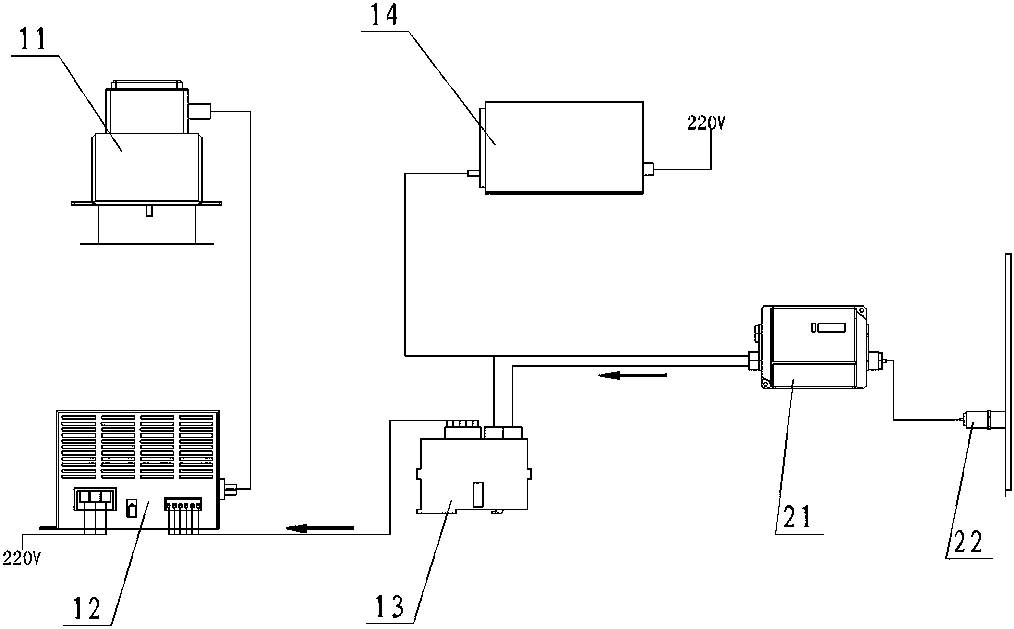

[0013] Such as figure 1 , figure 2 and image 3 As shown, a constant temperature control device for a microwave synthesizer includes a microwave control system 1 , a temperature monitoring system 2 , and a rotation drive system 3 .

[0014] Described microwave control system 1 comprises microwave launcher 11, microwave transmission controller 12, PLC controller 13, DC 24V power supply 14; Described temperature monitoring system 2 comprises infrared temperature detection controller 21, infrared temperature detection probe 22; The rotary drive system 3 includes a servo motor driver 31 , a servo motor 32 , a rotating platform 33 , a main shaft 34 , a main disk 35 , and a reactor 36 . The microwave launch controller 12 is connected with the microwave launcher 11 through an output data line, and the microwave launch controller 12 is externally connected to 220V mains; the control signal line of the PLC controller 13 is connected with the microwave launch controller 12, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com