PCB

A technology of metal blocks and heat dissipation holes, which is applied to printed circuit components, electrical components, printed circuits, etc., can solve the problems of poor heat dissipation performance of PCB, and achieve the effects of ensuring heat conduction performance, accelerating heat conduction performance, and enhancing heat dissipation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

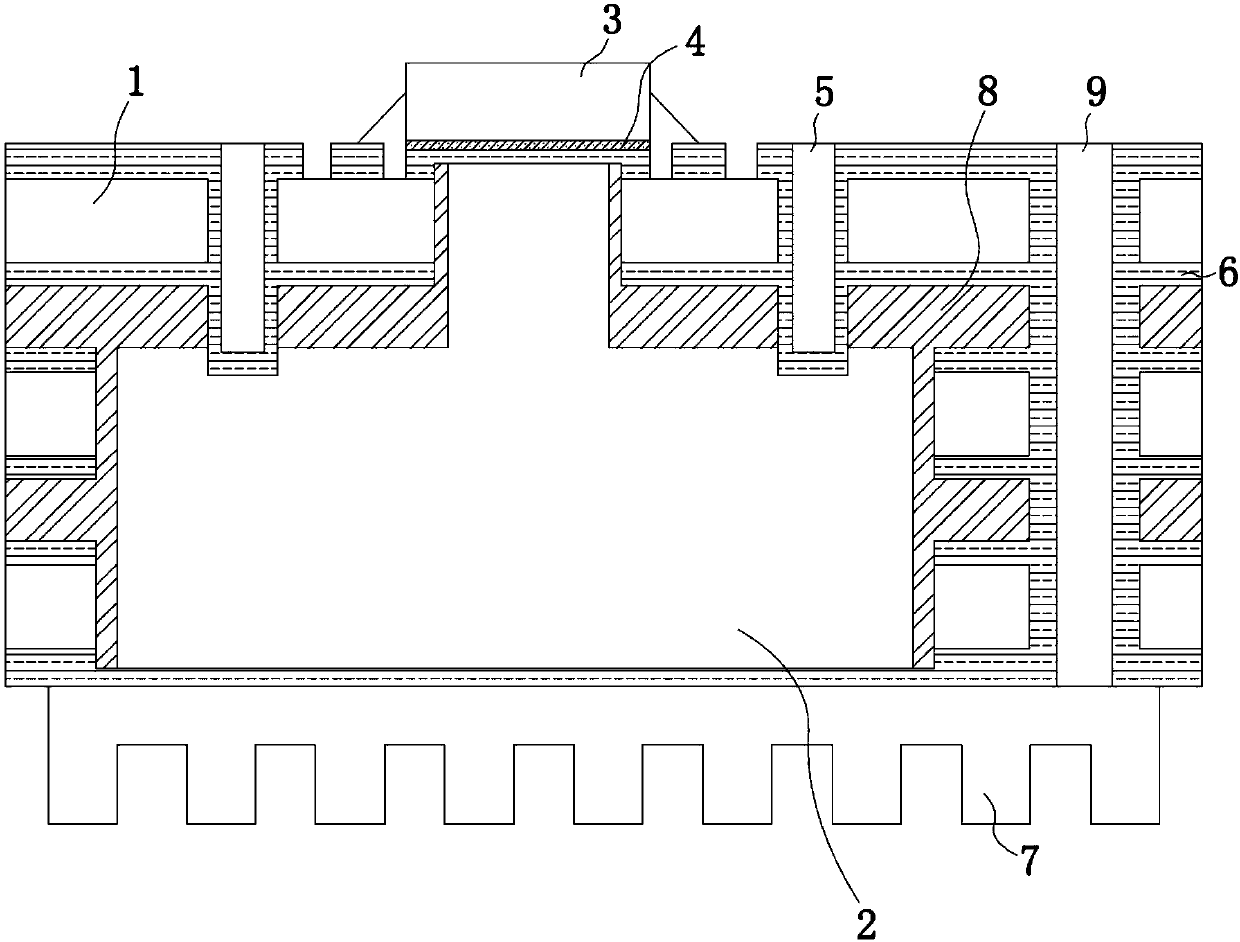

[0036] This embodiment provides a PCB. The PCB is formed by pressing three core boards, but the number is not limited thereto. For example, two or four core boards can also be formed by pressing together. Its structure is as Figure 1-Figure 3 As shown, components 3 are pasted on one side, and heat dissipation holes 5 and conduction holes 9 are opened. There are stepped grooves in the substrate 1 of the PCB, including smaller grooves and larger grooves, which form a convex shape. Ladder slot. A metal block 2 is buried inside the stepped groove, and the shape of the metal block 2 is the same as that of the stepped groove, both being convex. Wherein, the heat dissipation hole 5 is in the form of a blind hole, and the bottom of the blind hole extends to the metal block 2. In this embodiment, the heat dissipation hole 5 and the metal block 2 need to realize electrical conduction and heat conduction. The method adopted in this embodiment is to make the heat dissipation hole 5 met...

Embodiment 2

[0048] This embodiment provides a PCB. The PCB is formed by pressing three core boards, but the number is not limited thereto. For example, two or four core boards can also be formed by pressing together. For simplicity, only the differences between Embodiment 2 and Embodiment 1 are described. The difference is:

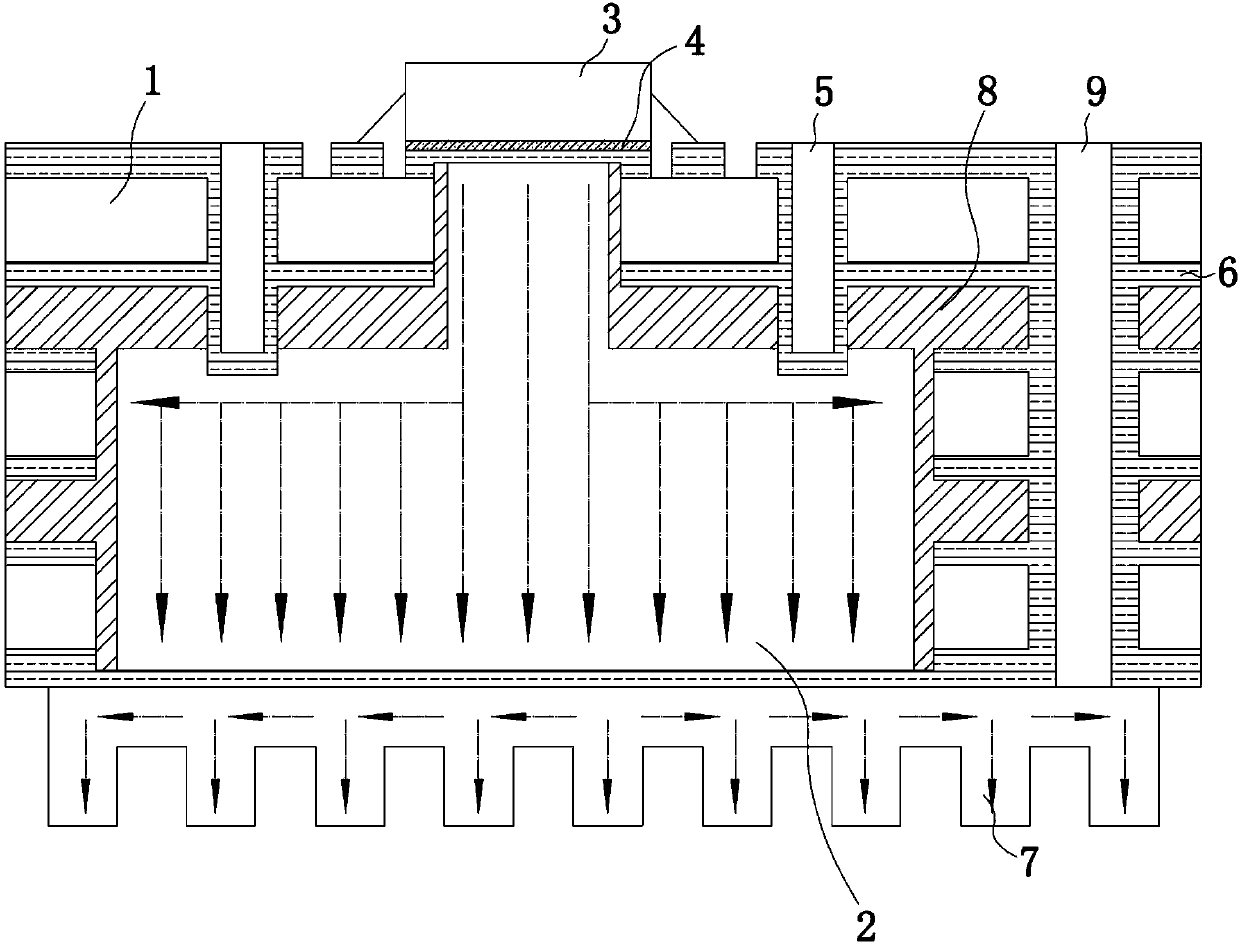

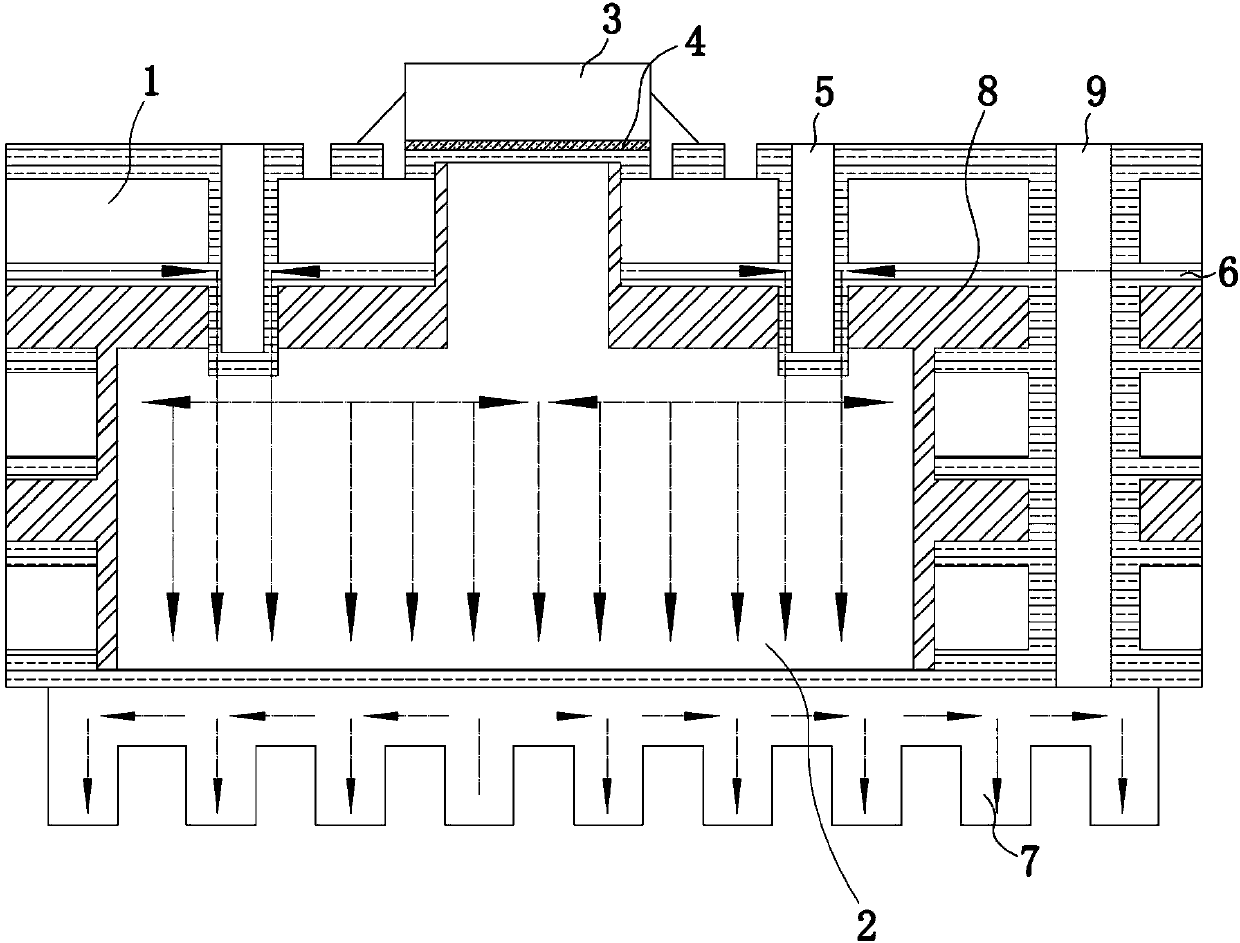

[0049] see Figure 4-Figure 6 , the heat dissipation hole 5 in this embodiment is in the form of a through hole, and the through hole is arranged through the metal block 2 and extends to the heat dissipation fin 7 . The setting of the through hole can increase the contact area with the metal block 2, and can conduct more heat to the metal block 2 quickly, and it is in contact with the heat sink 7, and the heat can be directly conducted to the metal block 2 through the copper layer on the inner wall of the through hole. The heat sink 7 performs dissipation.

[0050] The working principle of the second embodiment is described below:

[0051] Figure 5 It is a sche...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com