Shellfish automatic cleaning equipment

An automatic cleaning and equipment technology, applied in bivalve processing, crustacean processing, slaughtering and other directions, can solve the problems of high labor intensity, low production efficiency, unclean cleaning, etc., to improve work efficiency, reduce production costs, save money human effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

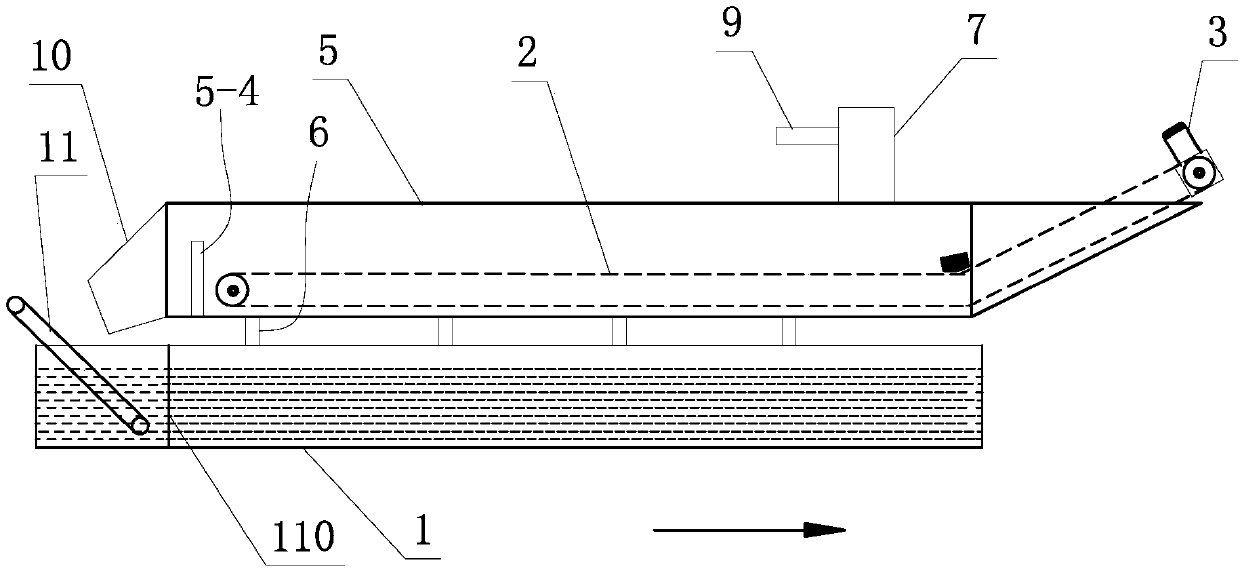

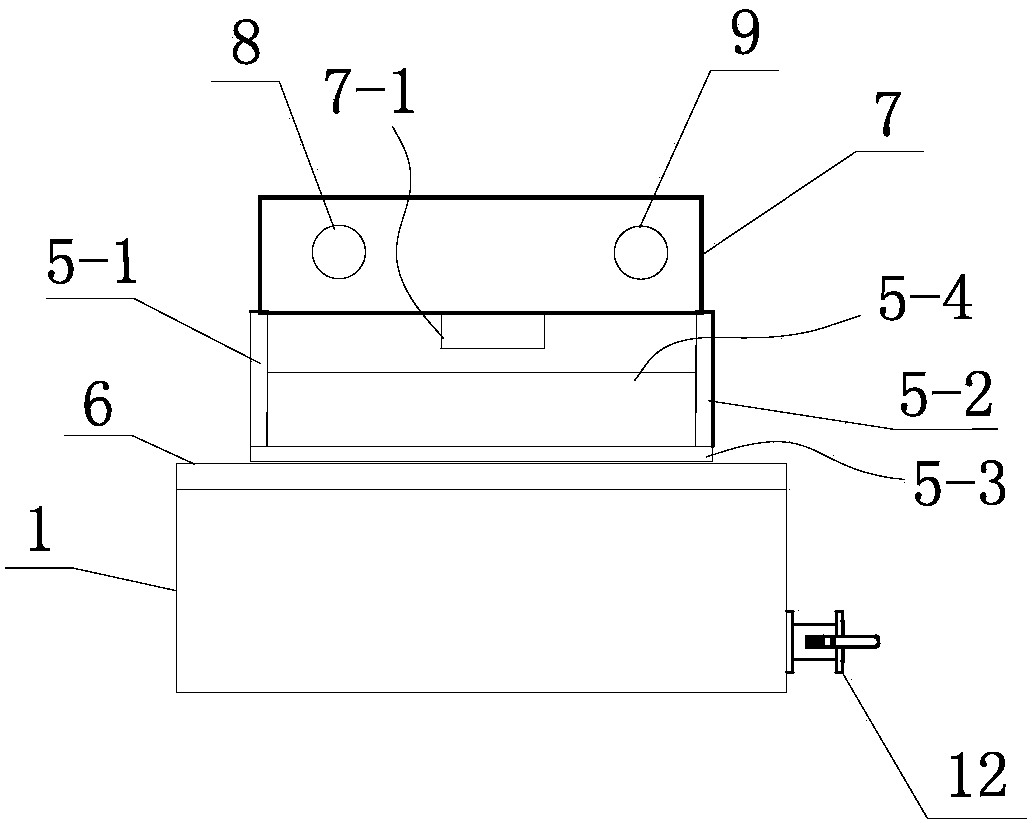

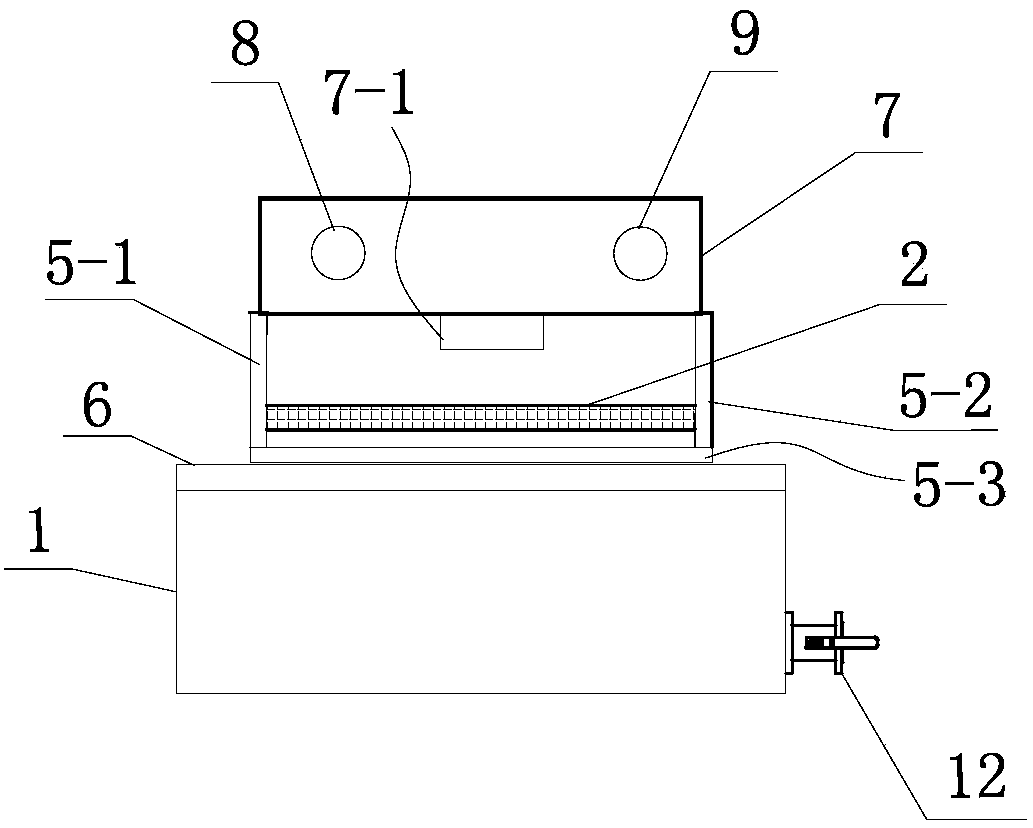

[0024] Such as Figure 1-3 As shown, the shellfish automatic cleaning equipment includes a water storage tank 1, a stainless steel mesh chain conveyor belt 2, a mesh chain belt drive motor 3, a cleaning water tank 5, a support 6, a water tank 7, a slope stainless steel mesh chain conveyor belt 11, a support 6 and The top of the water tank 1 is connected, and the cleaning water tank 5 is connected with the support 6 . The right part of the cleaning tank 5 is slope-shaped, and the left end is connected with a baffle plate 5-4, and the height of the baffle plate 5-4 is lower than the overall height of the cleaning tank 5. figure 1 Arrows in represent the direction of travel of the stainless steel mesh chain conveyor belt 2.

[0025] The cleaning tank 5 comprises a first side plate 5-1, a second side plate 5-2, a bottom plate 5-3, a baffle plate 5-4, and the first side plate 5-1 and the second side plate 5-2 are connected with the bottom plate 5 respectively. -3 is vertically co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com