Crane used for mounting of bridge prefabricated hanging boards and hoisting technology of crane

A crane and installation technology are applied in the field of bridge prefabricated siding installation cranes and their hoisting technology, which can solve the problems of consuming equipment shifts, long working hours, and diesel consumption by truck cranes, and save mechanical shifts and work efficiency. High, no diesel consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

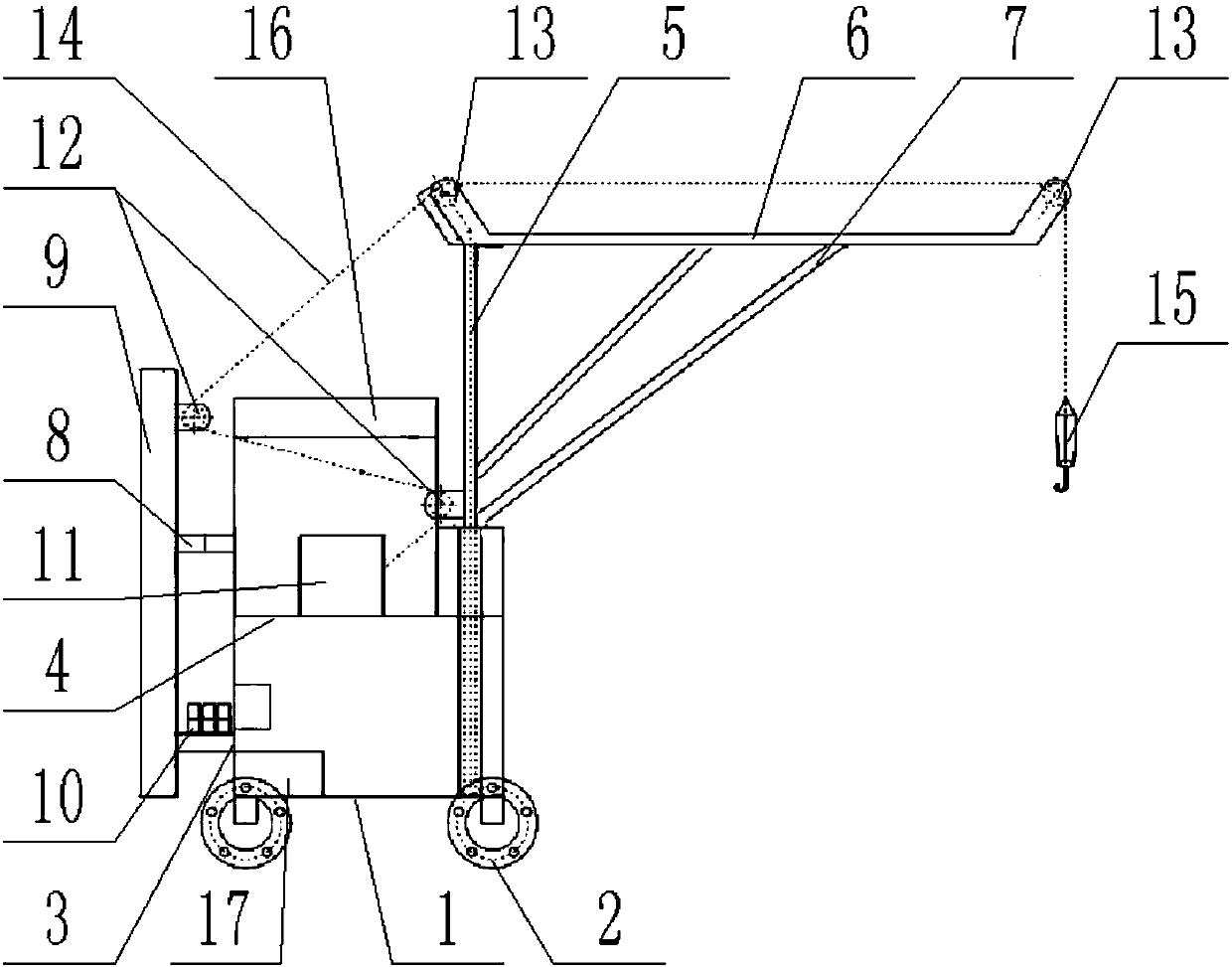

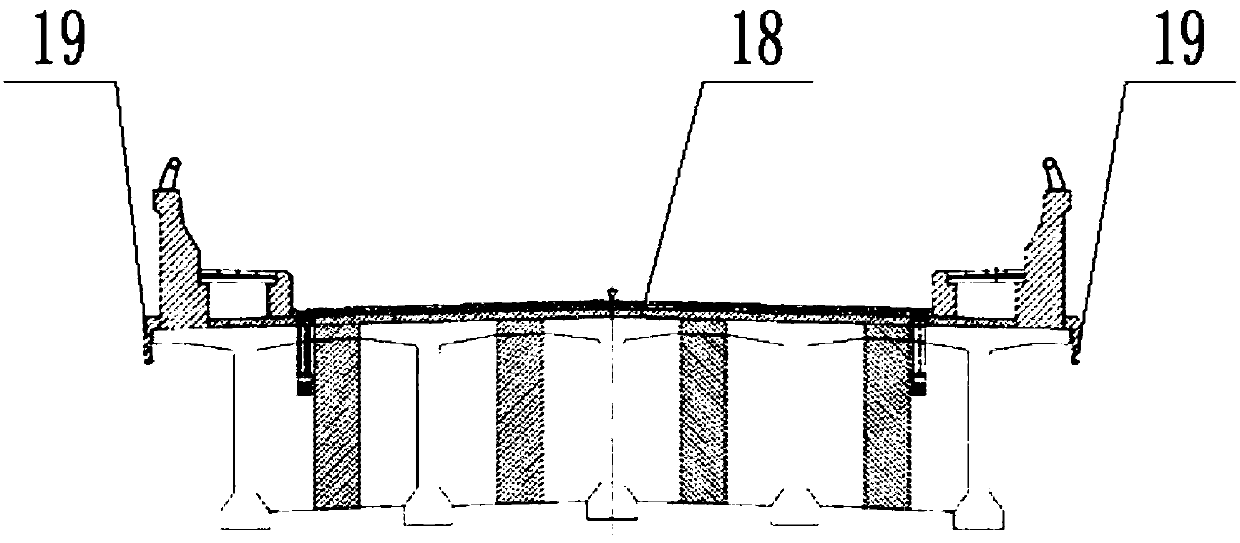

[0025] Such as figure 1 and figure 2 As shown, a crane for installing bridge prefabricated hanging slabs, including a base 1, the bottom of the base 1 is equipped with wheels 2, and it is characterized in that four corners of the upper surface of the base 1 are provided with vertically upward supports 3 , the upper surfaces of the four brackets 3 are provided with a horizontal support plate 4, a sleeve is provided at the middle position of one side of the upper surface of the base 1, and a vertical shaft 5 is provided in the sleeve, and the sleeve is connected with the vertical shaft. Rotary bearings are arranged between the shafts 5, and a horizontal frame 6 is welded on the top of the vertical shaft 5, and the horizontal frame 6 protrudes outside the support plate 4, and a reinforcing bracket is provided between the horizontal frame 6 and the vertical sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com