Horizontal balance testing rack of mill knife

A balance testing and leveling technology, applied in measuring device, mechanical measuring device, mechanical diameter measurement, etc., can solve the problems of outer diameter deviation, cumbersome operation, time-consuming and labor-intensive, etc., so as to reduce the installation cost, facilitate production management, and improve work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

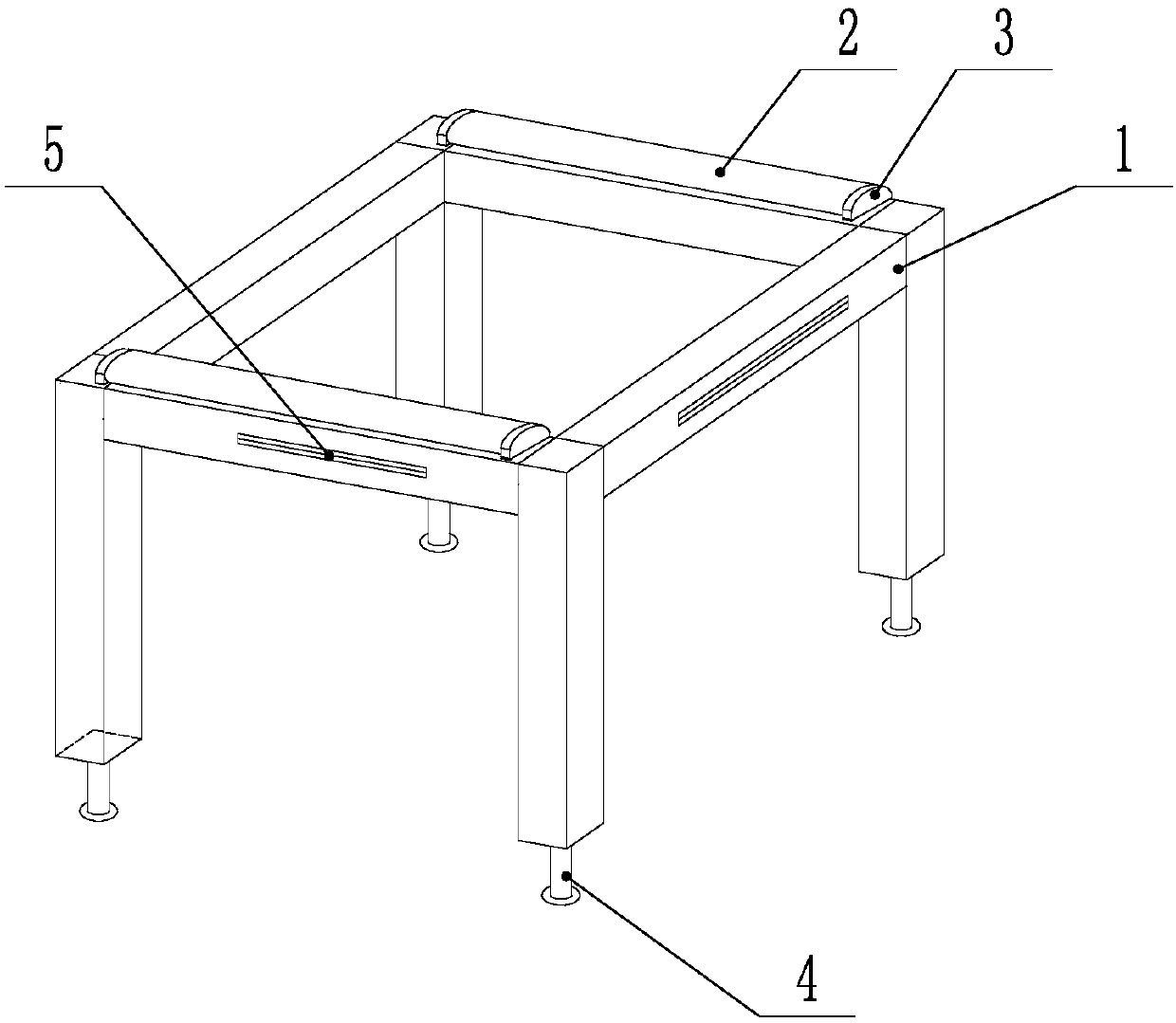

[0011] like figure 1 As shown, the present invention includes a frame body 1, which is characterized in that a horizontal bar 2 is arranged above the top, front and rear sides of the frame body 1, and the horizontal bar 2 is fixed on the upper side of the frame body 1 by fixing brackets 3 at both ends. The lower end of the frame leg of the frame body 1 is provided with an adjustment bracket 4, and a level ruler 5 is provided around the frame body 1, and the horizontal bar 2 is cylindrical, and the adjustment bracket 4 is socketed with the frame body 1 through threads.

[0012] Working principle of the present invention: place the end shafts at both ends of the sharpening knife on the horizontal bar 2, because the horizontal bar 2 is cylindrical, so the contact surface area between the end shaft of the sharpening knife and the horizontal bar 2 is reduced to the minimum, reducing the grinding time. The frictional force between the end shaft and the horizontal bar 2, adjust the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com