Reciprocating oil seal performance testing testbed

A test bench, reciprocating technology, applied in the field of test benches, can solve problems such as polluting the environment, threats to personal safety, and reduced service life of mechanical equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings.

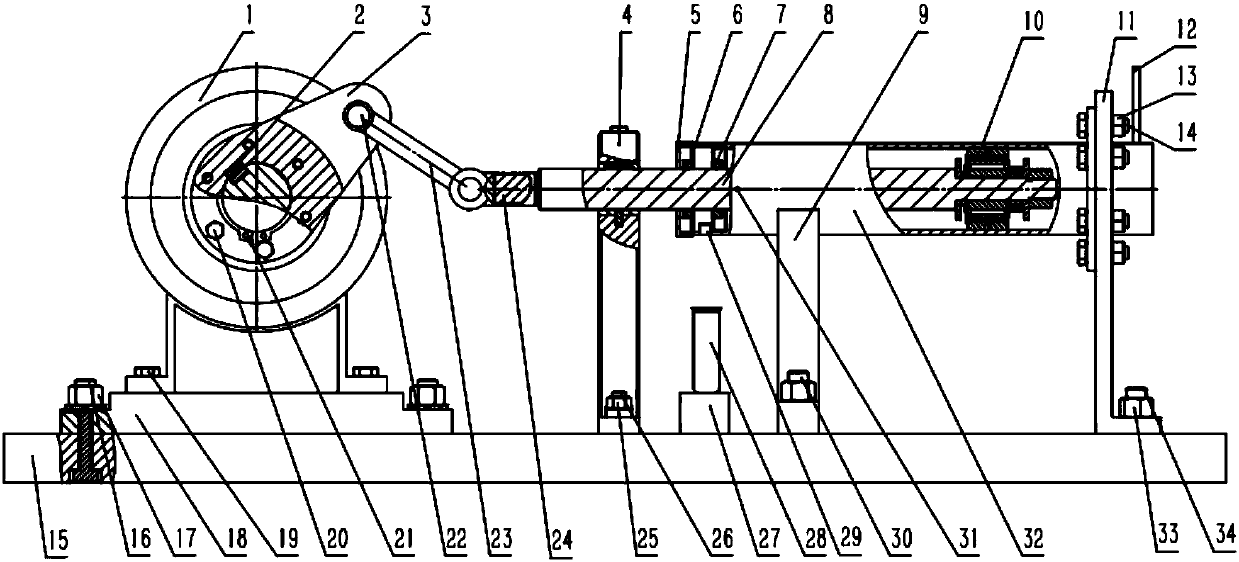

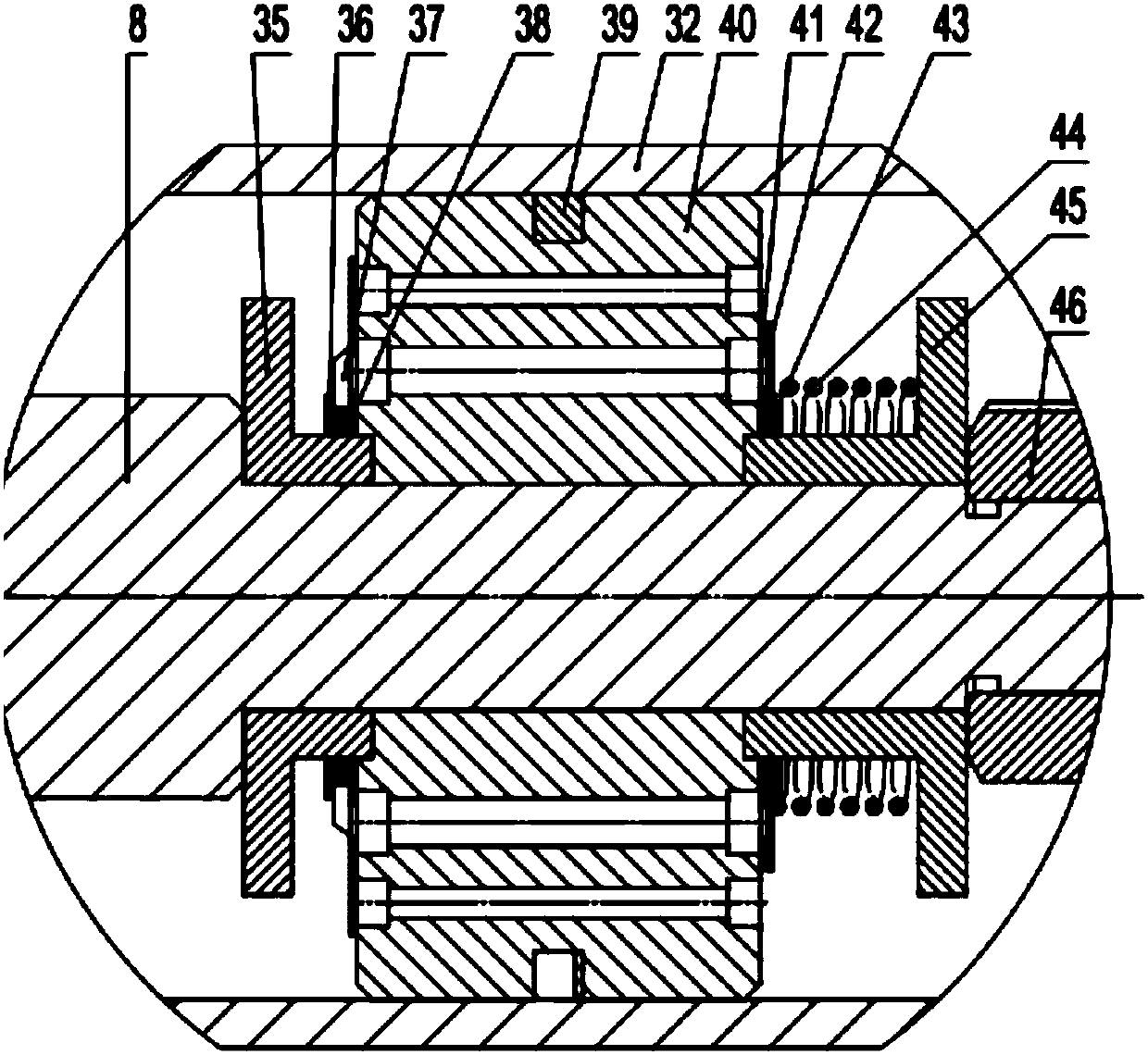

[0016] refer to figure 1 with figure 2 , a reciprocating oil seal performance test bench, including a motor 1, a crank 3, a connecting rod 23, a single clevis 24, a sliding bearing 4, an end cover 5, an oil seal 7, a cylinder 32, a valve system 10, an oil supply chamber 12, etc. part. The motor 1 is fixed on the bottom plate 17, and the bottom plate 17 is fixed on the T-slot base 15 by bolts 16. The motor output shaft 1 is connected to one end of the crank 3 through the key 2, and the other end of the crank 3 is connected to the connecting rod through the pin shaft 22. 23 connected, the connecting rod 23 is connected with the single clevis 24, the single clevis 24 is connected with the piston rod 8 through internal and external threads, thereby driving the piston rod 8 to complete the stretching and compression stroke, one end of the crank 2 is fixed with a sleeve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com