Physical simulation method for enabling water injection induced micro-fracture extension law to reappear under formation conditions

A technology of formation conditions and physical simulation, applied in measuring devices, suspension and porous material analysis, instruments, etc., can solve the problems of calculating the change of rock core permeability, there is no physical simulation method for water injection micro-fractures, and it cannot be realized.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

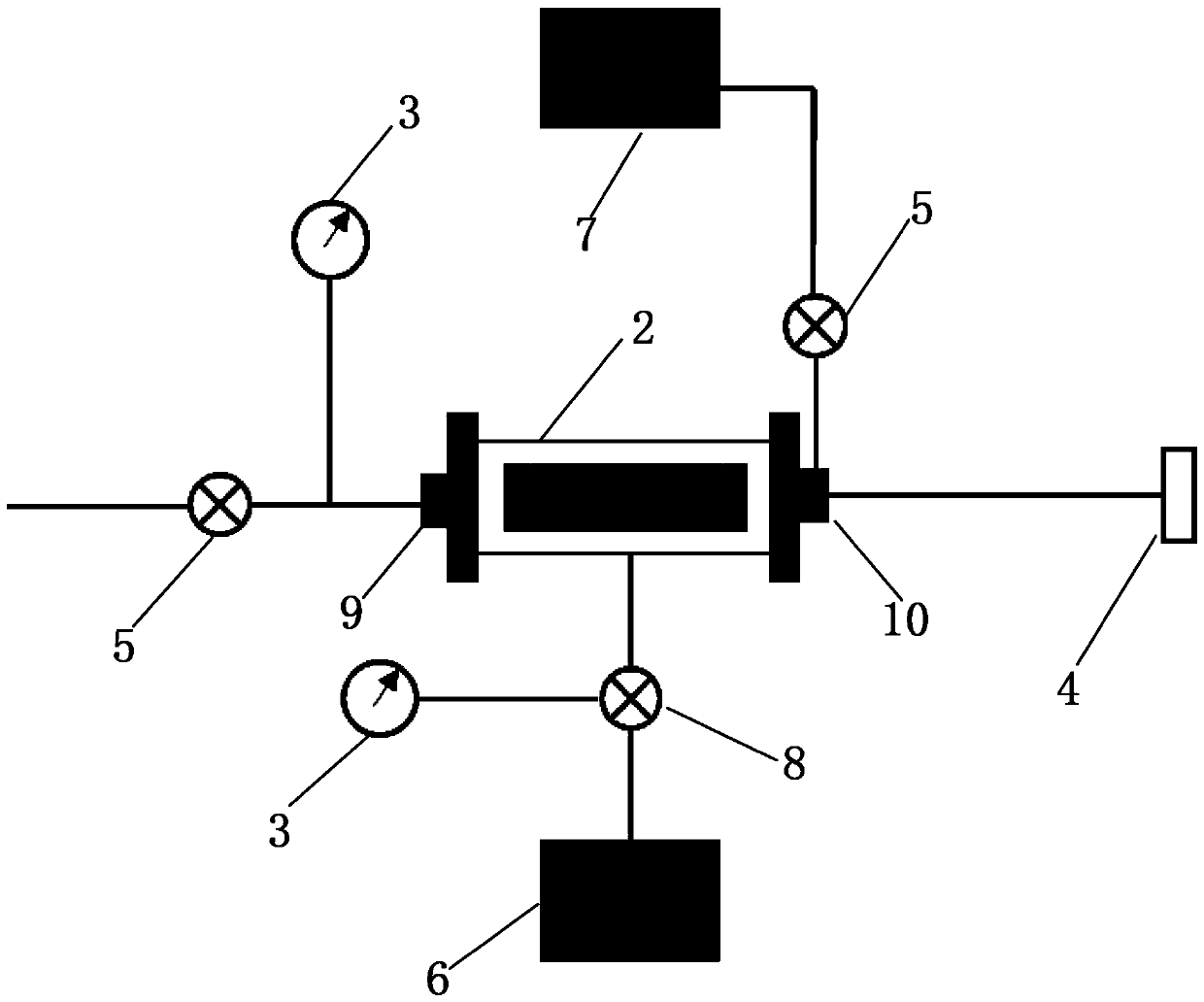

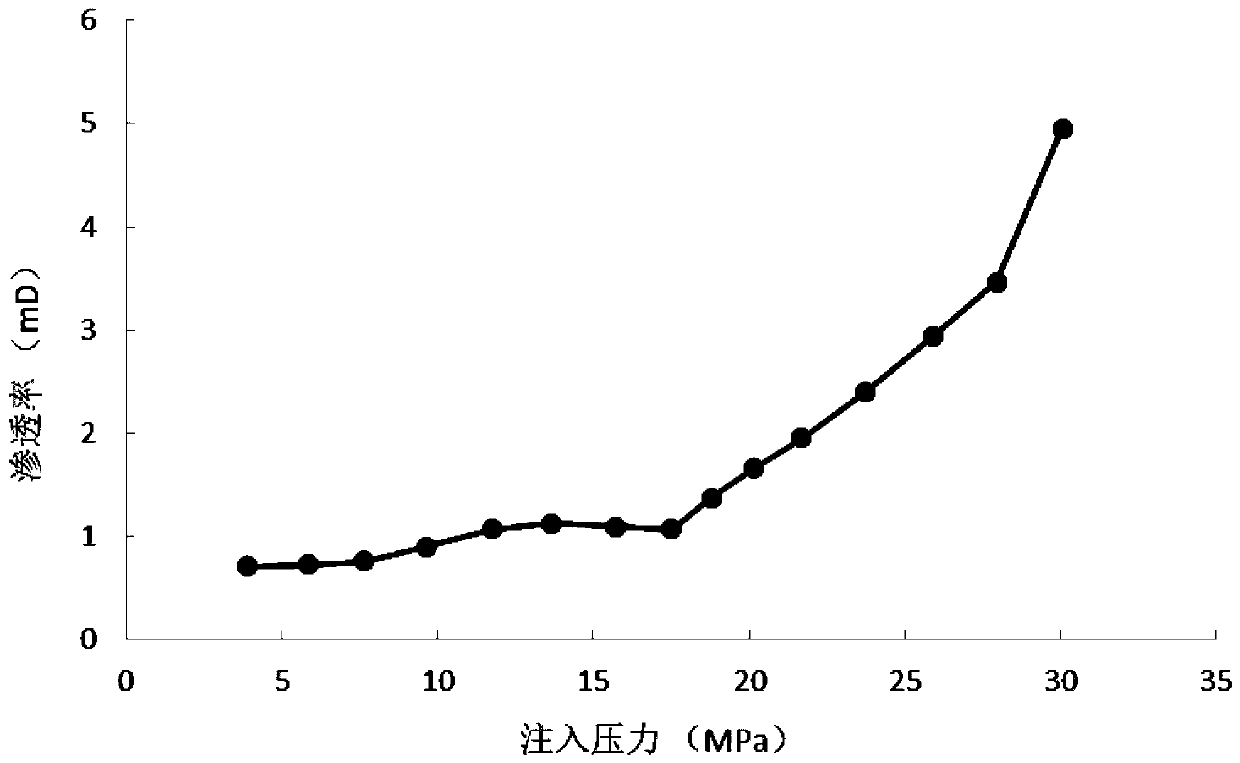

[0046] In this embodiment, the experimental core A is selected as a cylindrical core with a diameter of 3.34 cm and a length of 30.2 cm. The core permeability is 0.71mD, the control experiment temperature is 80℃, and the rock fracture pressure is 22MPa. Pressure gauge 3 has a range of 0-35MPa and an accuracy of 0.25. Confining pressure booster pump 6 has a pressure range of 0-35MPa and an accuracy of 0.1MPa. Generally, the confining pressure needs to be greater than the axial pressure. Axial pressure booster pump 7 has a pressure range of 0-35MPa and an accuracy of 0.1MPa.

[0047] Such as figure 1 As shown, a physical simulation method for reproducing the extension law of micro-fractures induced by water injection under formation conditions includes the following steps:

[0048] ① Select the core, clean, dry and saturate the core with oil;

[0049]②Using the triaxial core pressurization experimental system, put the oil-saturated core in the triaxial core holder 2 and plac...

Embodiment 2

[0061] In this embodiment, the experimental core B is selected as a cylindrical core with a diameter of 3.52 cm and a length of 31.4 cm. The core permeability is 0.92mD, the control experiment temperature is 80℃, and the rock fracture pressure is 23MPa. Pressure gauge 3 has a range of 0-35MPa and an accuracy of 0.25. Confining pressure booster pump 6 has a pressure range of 0-35MPa and an accuracy of 0.1MPa. Generally, the confining pressure needs to be greater than the axial pressure. Axial pressure booster pump 7 has a pressure range of 0-35MPa and an accuracy of 0.1MPa.

[0062] Such as figure 1 As shown, a physical simulation method for reproducing the extension law of micro-fractures induced by water injection under formation conditions includes the following steps:

[0063] ① Select the core, clean, dry and saturate the core with oil;

[0064] ②Using the triaxial core pressurization experimental system, put the oil-saturated core in the triaxial core holder 2 and pla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com