Continuous hole type knife template and machining method thereof

A processing method and technology of knife templates, which are applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of poor effect of fixed die-cutting blades on knife templates, difficult processing of installed knife seams, and high manufacturing difficulty, etc., to achieve easy The effect of low processing and manufacturing difficulty and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0088] In order to better explain the present invention and facilitate understanding, the present invention will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

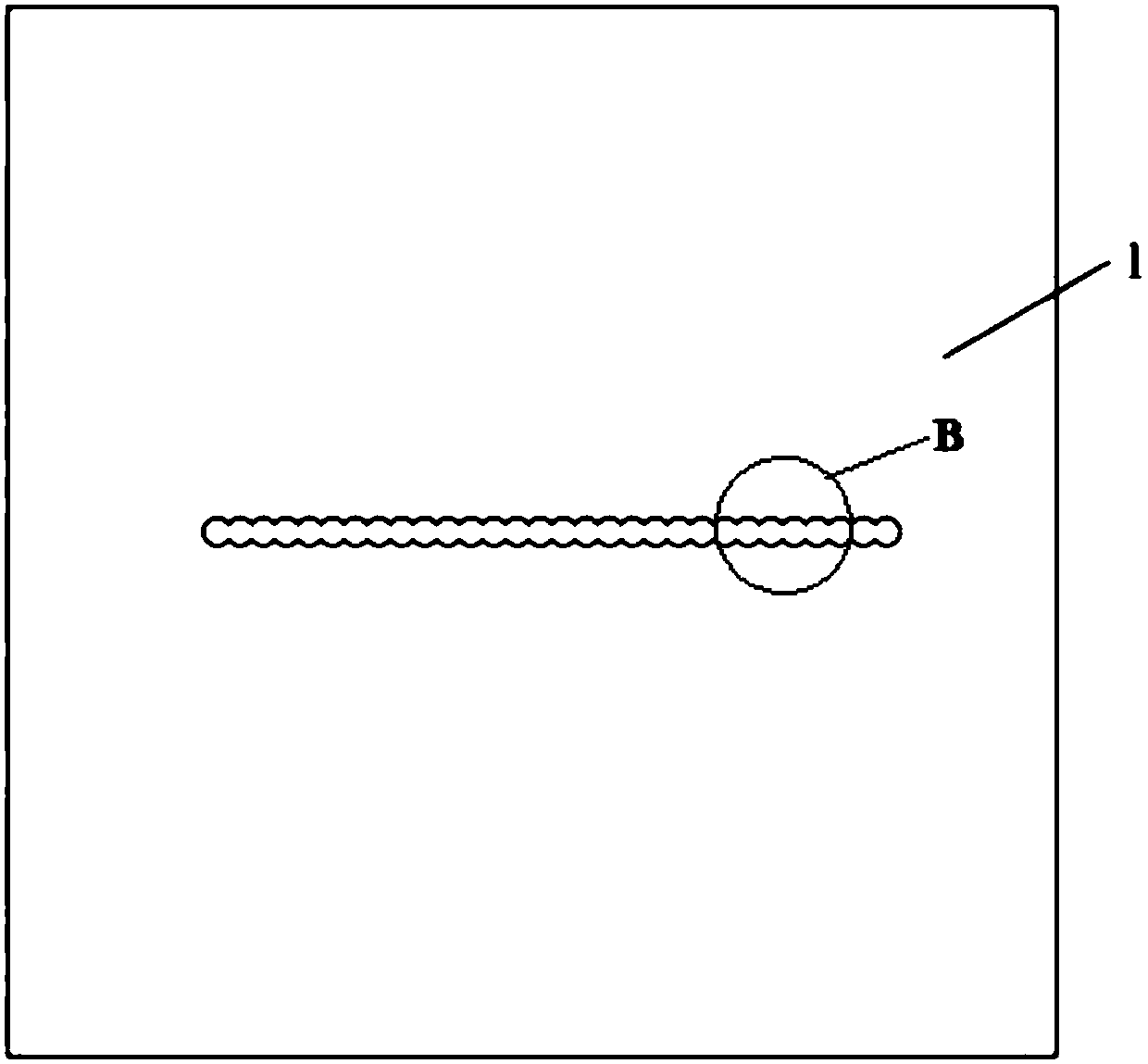

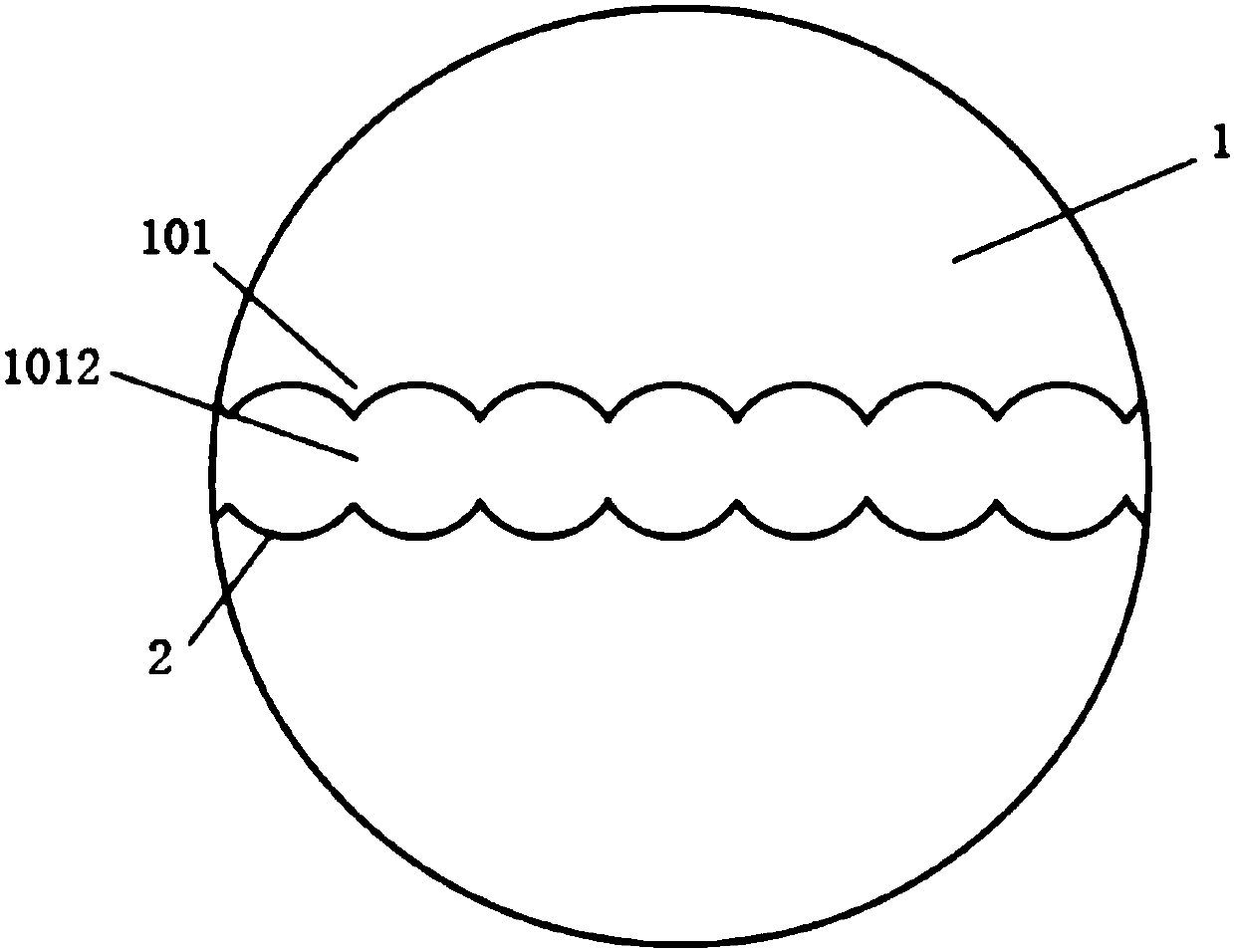

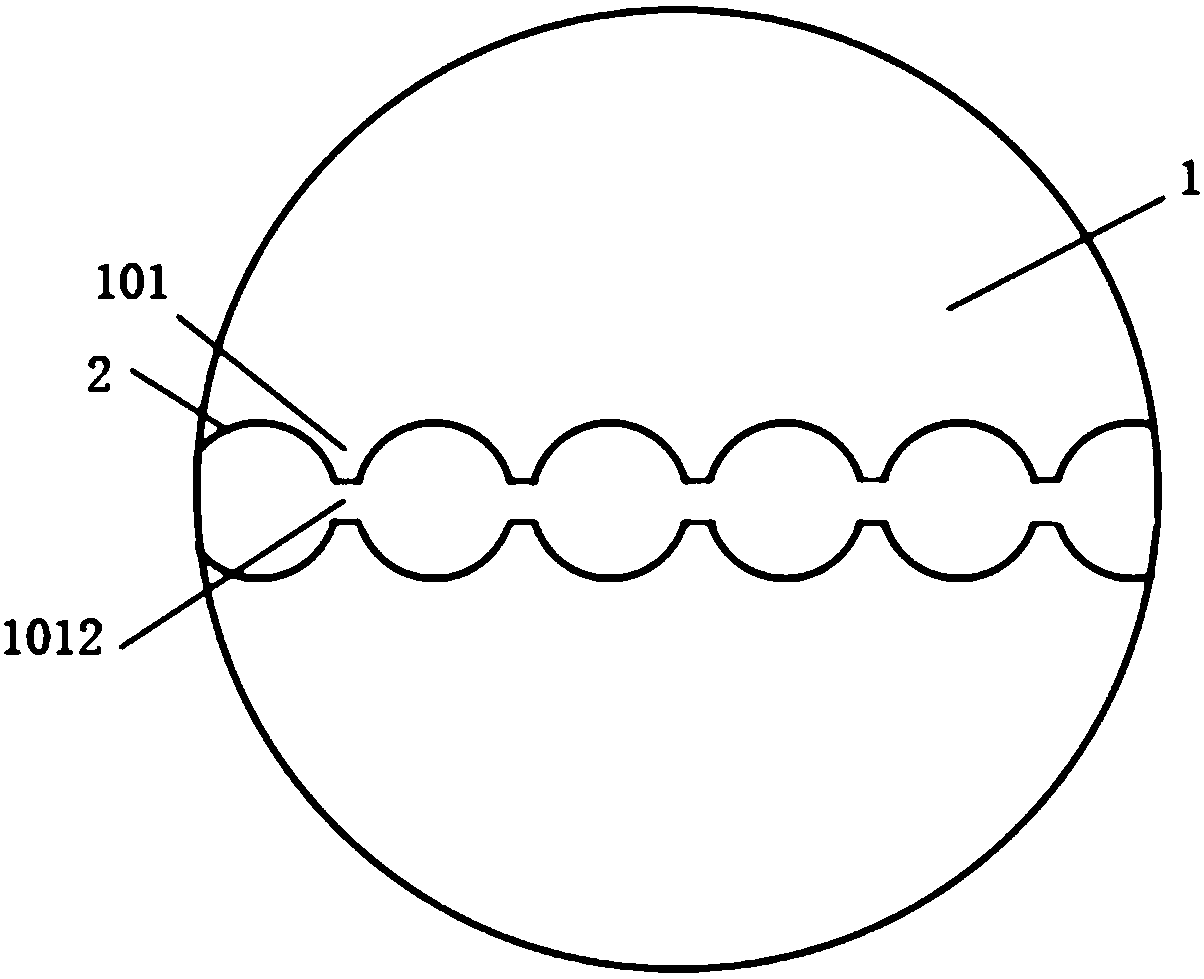

[0089] The first embodiment of the knife seam installation

[0090] Such as Figure 1-Figure 8 As shown, this embodiment discloses a knife template 1 with continuous holes. For the convenience of description, the side of the knife template corresponding to the blade on which the blade is installed is called the first side, and the side opposite to the blade is called the second side. It can be understood that the same die plate can also be installed from one side or vice versa according to the needs of die processing. Then, under the condition of no conflict, when the blade is installed in reverse, correspondingly, the side corresponding to the blade is still called the first side, and the side opposite to the blade is called the second side.

[0091] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com