Tray Conveyor Steering Equipment

A technology for steering equipment and trays, applied to conveyors, conveyor objects, transportation and packaging, etc., can solve problems such as reducing enterprise market competitiveness, high labor intensity, and automation equipment slowdown, so as to improve market competitiveness and turn The angle is easy to control and the effect of improving the degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below in conjunction with accompanying drawing and embodiment, further elaborate the present invention.

[0035] The orientations involved in this specification are all subject to the orientations shown in the drawings, which only represent relative positional relationships, not absolute positional relationships.

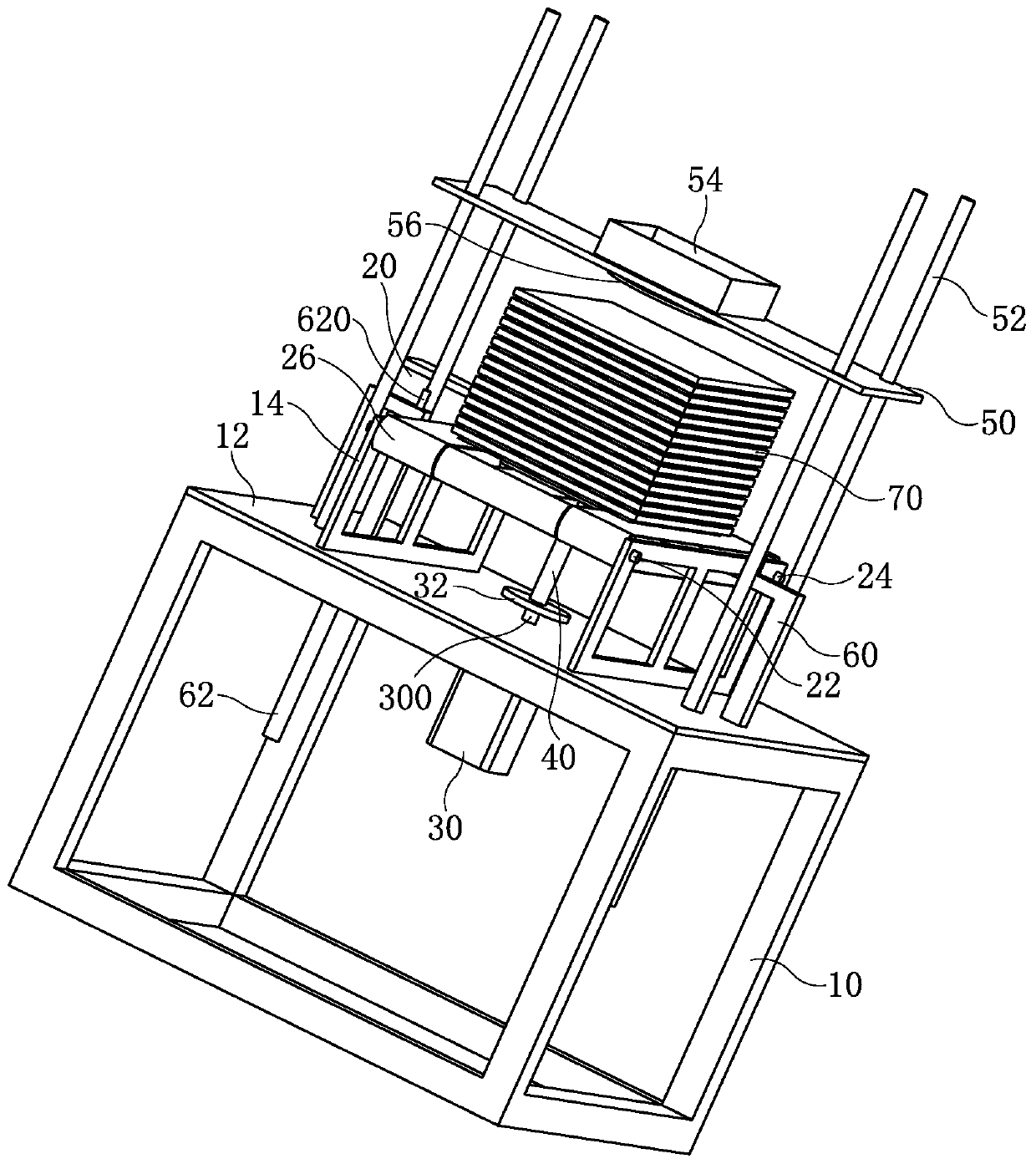

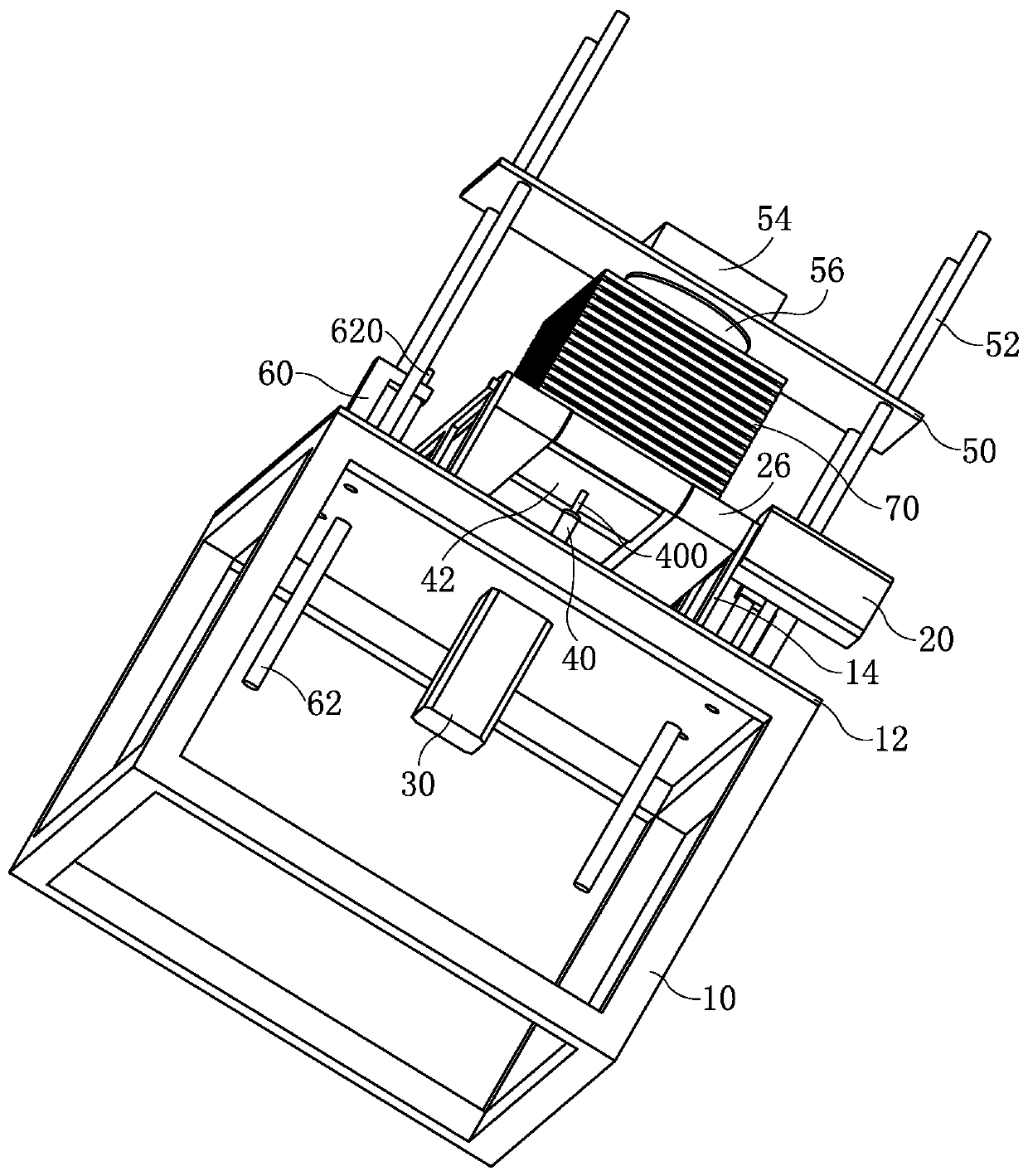

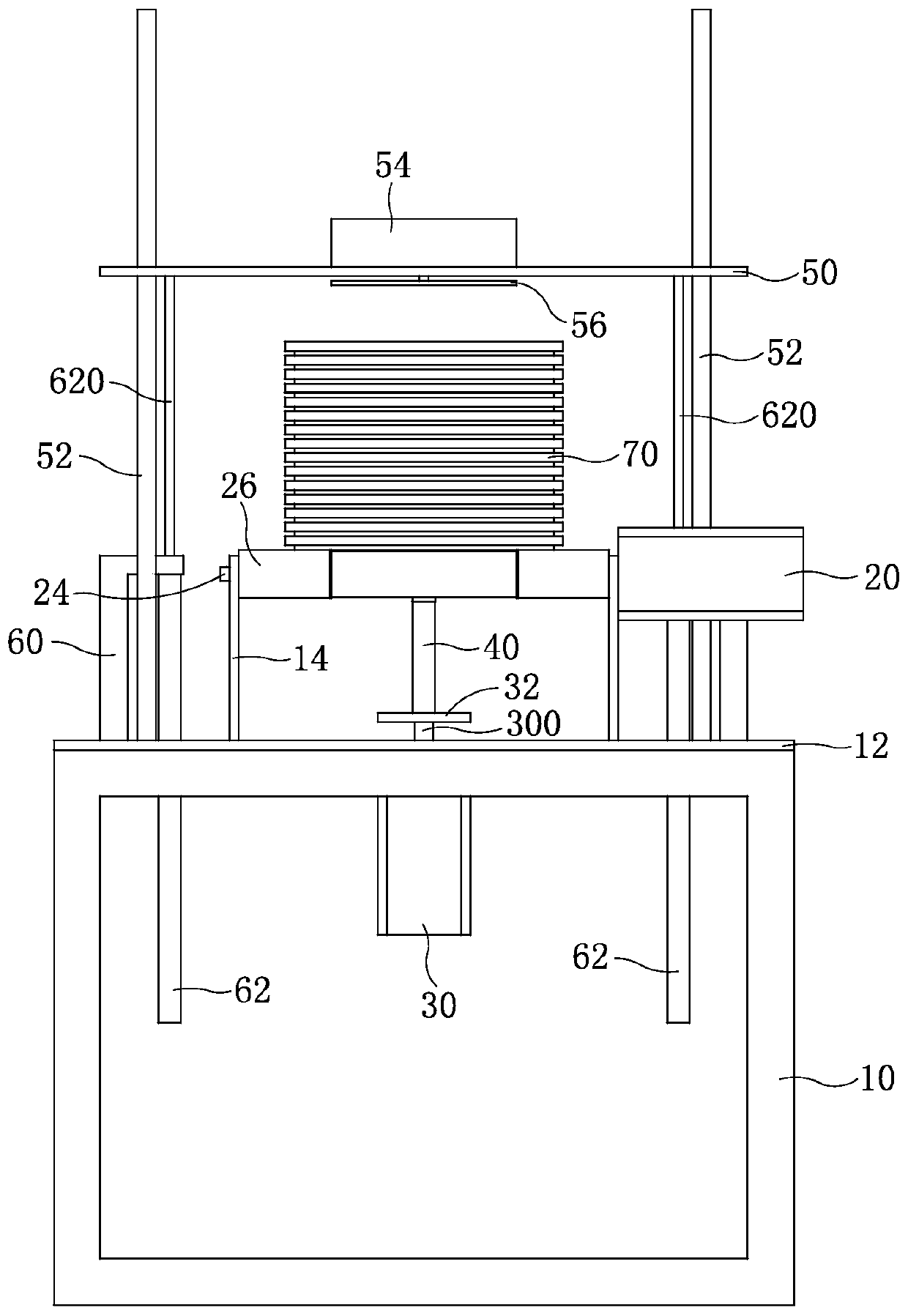

[0036] Such as figure 1 and figure 2 Commonly shown, a kind of feeding tray conveying and steering equipment includes a bracket 10, on which a tray pallet 42 for supporting the feeding tray 70 is installed. In this embodiment, the bracket 10 includes a chassis of a frame structure and The mounting plate 12 on the top of the frame, the tray pallet 42 is installed above the mounting plate 12. The bottom of the tray supporting plate 42 is equipped with a tray lifting device and a rotating motor 30 that can drive the tray supporting plate 42 to rotate after the tray supporting plate 42 is lifted. In the present embodiment, the output shaft 300 of the tray lift...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com