Electro-pneumatic brake control system

A braking control and pneumatic technology, applied in the direction of brakes, automatic starting devices, braking transmission devices, etc., can solve problems such as complex structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

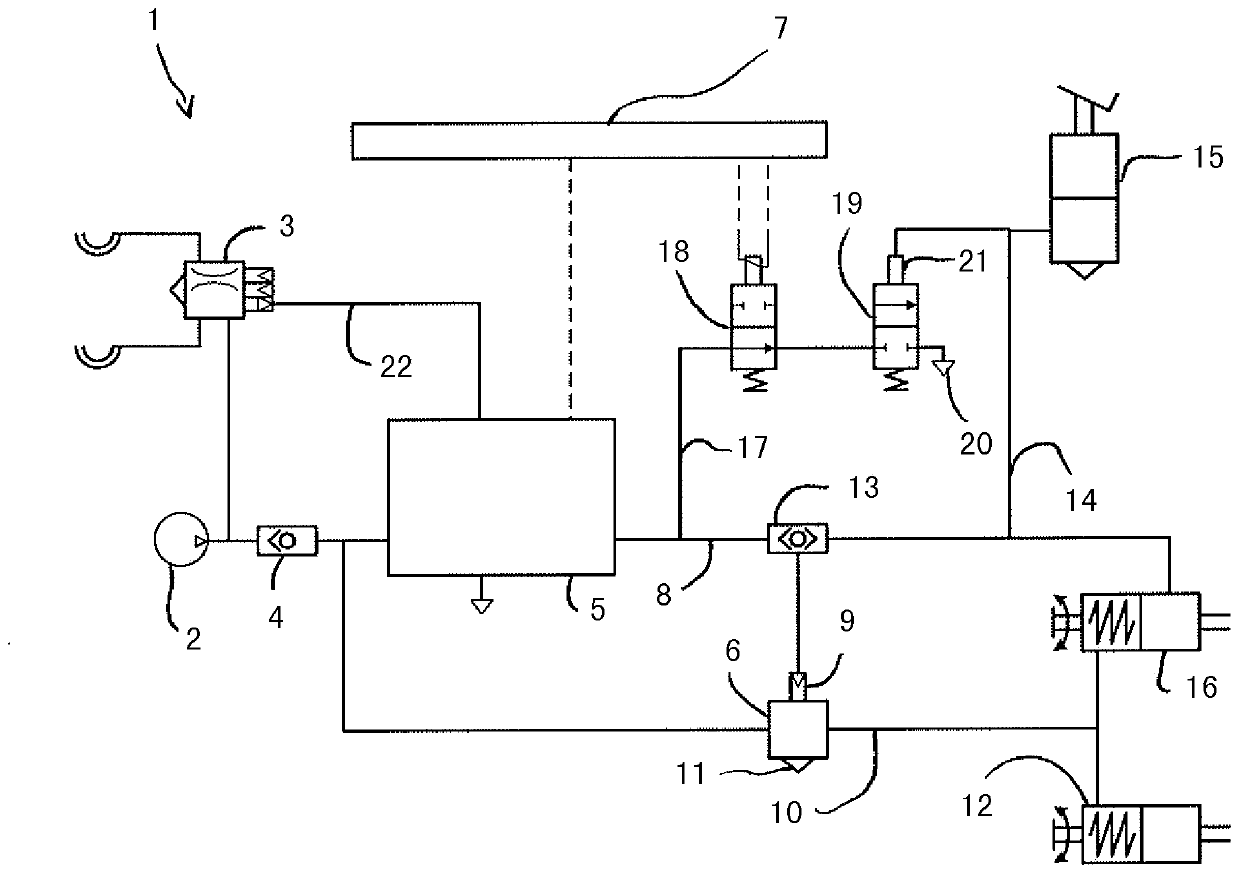

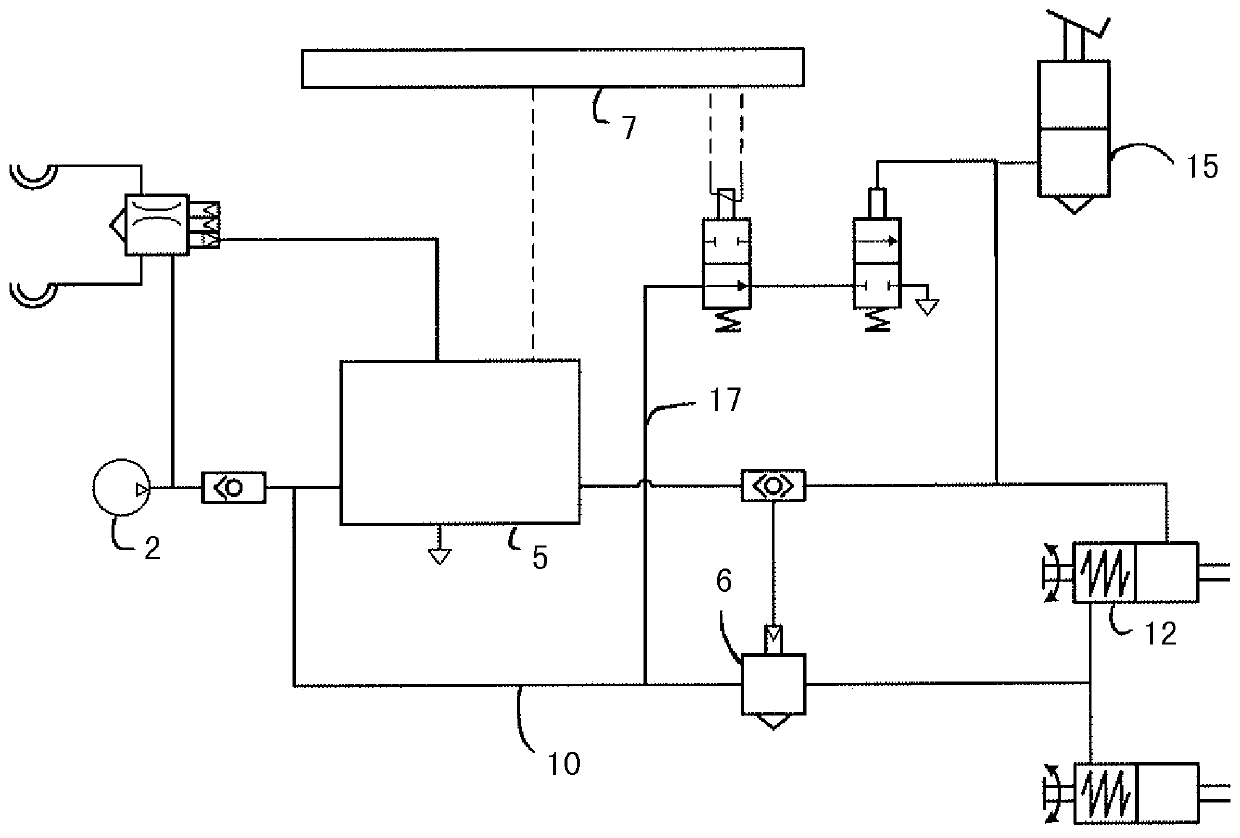

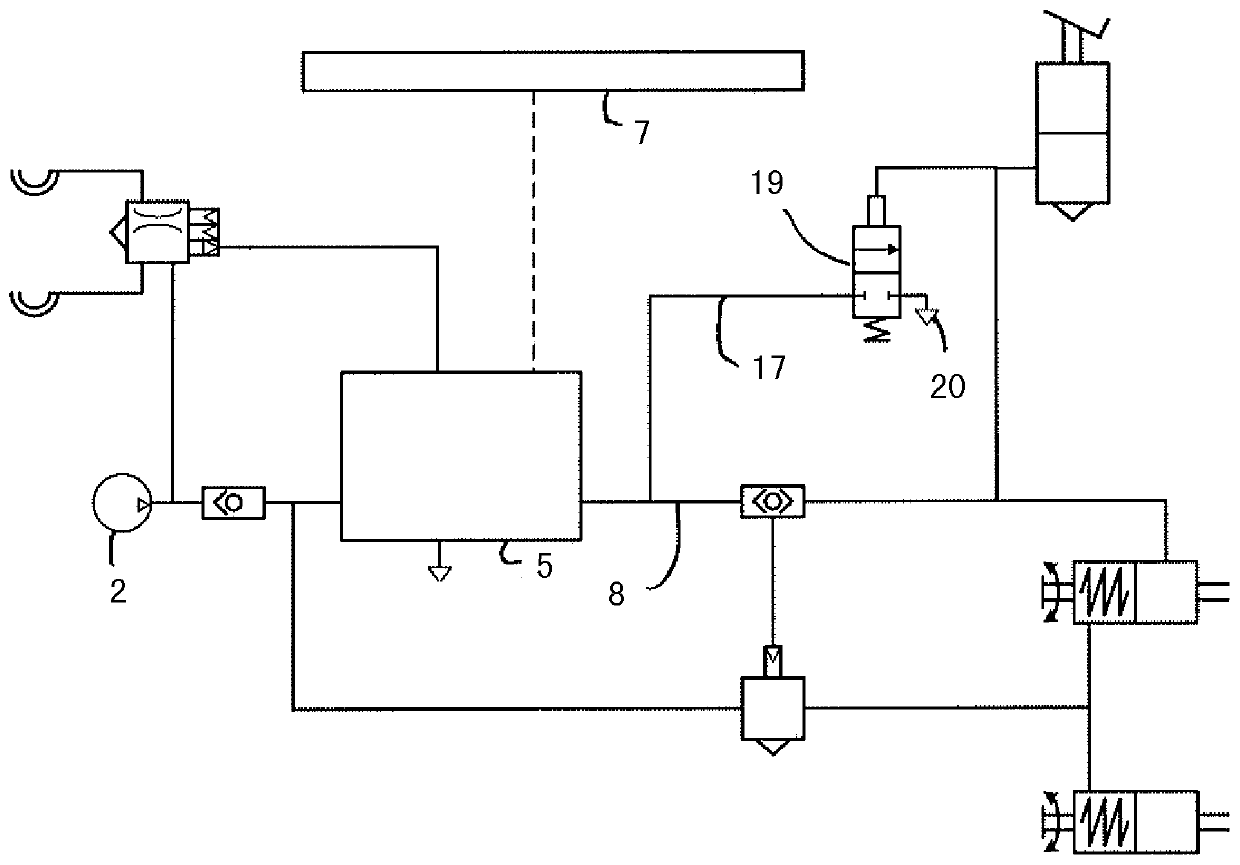

[0027] according to figure 1 , the electro-pneumatic brake control system 1 comprises a compressed air supply unit 2, by means of which, in addition to supplying compressed air to the trailer service brake system 3 (guaranteed by a check valve 4), a parking brake valve assembly is supplied 5 and relay valve 6 supply compressed air.

[0028] Here, the parking brake valve assembly 5 is actuated electronically via an electronic control unit 7 . As long as the control unit 7 works as intended, the air pressure in the control line 8 can be increased or reduced to atmospheric pressure by the control unit, which then acts on the control interface 9 of the relay valve 6, As a result, the supply line 10 is provided on the output side of the relay valve 6 with the same equal air pressure. The supply line 10 is fed into the spring accumulator brake cylinder 12 on the output side of the relay valve 6 so that the corresponding parking brake is released when the compressed air is supplie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com