Centralized oil mist removal system for optical cable water stop cable paste spraying

A water-blocking cable paste and oil mist technology, which is applied in the direction of spraying devices, liquid separation into beads, granulation, and separation of dispersed particles, can solve problems such as inability to put into use, environmental pollution, and material waste, and achieve reasonable structural design and improved Production environment, the effect of reducing the amount of fine dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

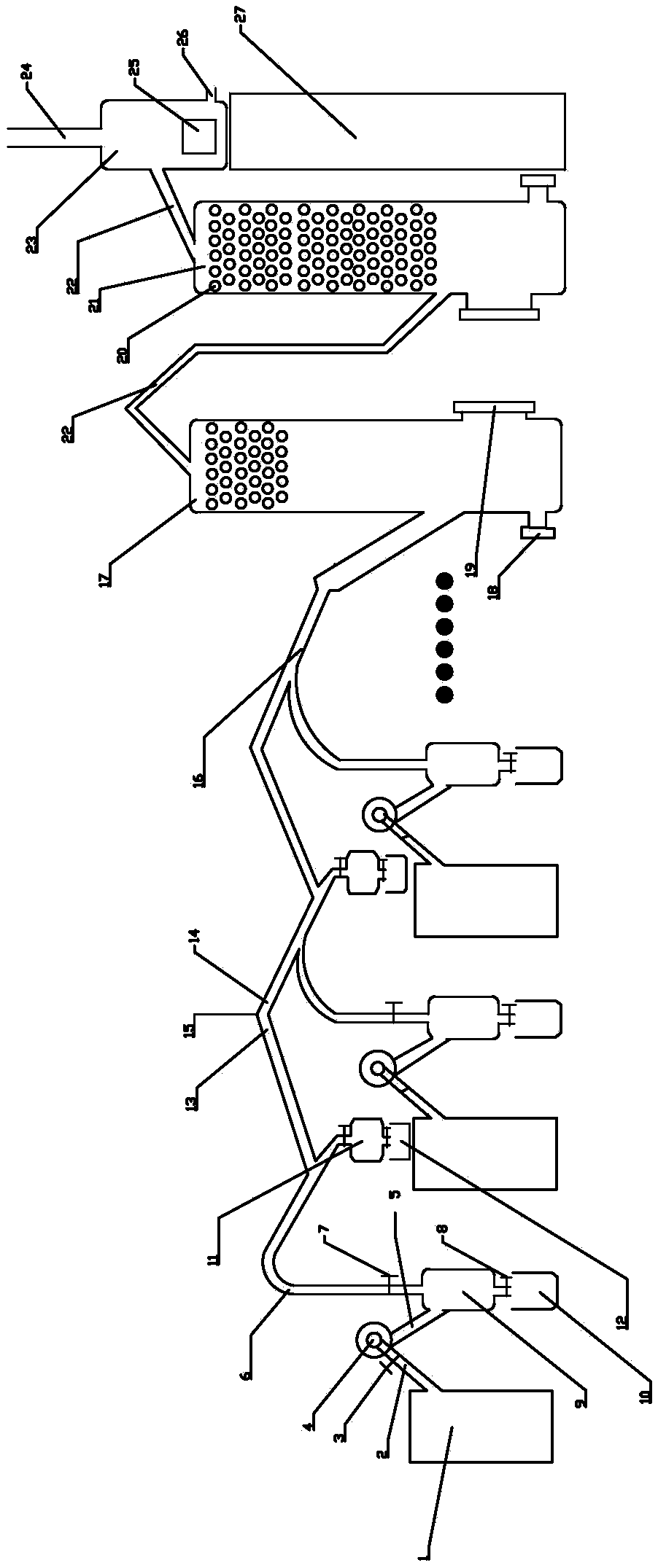

[0018] In order to clearly illustrate the technical features of this solution, the present invention will be described in detail below through specific implementation modes and in conjunction with the accompanying drawings.

[0019] Such as figure 1 As shown in , a centralized oil mist removal system for optical cable water blocking cable paste spraying, the system includes an oil mist pretreatment system and an oil mist treatment system; the oil mist pretreatment system includes several storage devices connected in sequence through pipelines And a storage device, the storage device includes a storage device and a secondary storage device connected by an elbow; the storage device includes a cable paste sprayer 1 and a high-pressure centrifugal fan connected to it by an upwardly inclined pipeline 2 4. A wind pressure automatic cut-off valve 3 is provided in the upward-inclining pipeline 2, the upward-inclining pipeline 2 is connected to the air inlet of the high-pressure centri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com