Upper swing arm being simple in structure

A technology with a simple structure and an arm body, applied in the field of the upper swing arm, can solve the problems of low processing precision, high manufacturing difficulty, high cost, etc., and achieve the effects of facilitating production and processing, ensuring shock absorption effect, and avoiding collision damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, the technical solutions in the embodiments of the present invention will be clearly described below in conjunction with the drawings in the embodiments of the present invention.

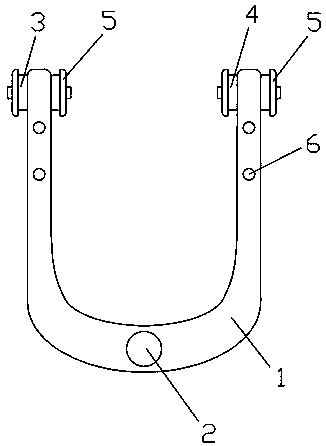

[0015] Such as figure 1 As shown, the upper swing arm with a simple structure described in this embodiment includes a U-shaped upper swing arm body 1, and a mounting shaft hole for installing a ball stud at the center of the upper swing arm body 1. 2. And the first connecting shaft hole (not shown in the figure) and the second connecting shaft hole (not shown in the figure) welded to the two ends of the upper swing arm body 1, the first Anti-collision flanges 5 are provided on the upper swing arm body 1 at both ends of the connecting shaft hole and the second connecting shaft hole, and a plurality of bolts are provided on the two vertical arms of the upper swing arm body 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com