Heavy automatic grass bale breaking and feeding device

A technology of feeding device and straw bales, applied in the field of agricultural and animal husbandry machinery, can solve the problems of large manpower input and low production efficiency, and achieve the effects of improving efficiency, saving manpower and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention and its effects will be further described below in conjunction with the accompanying drawings and embodiments.

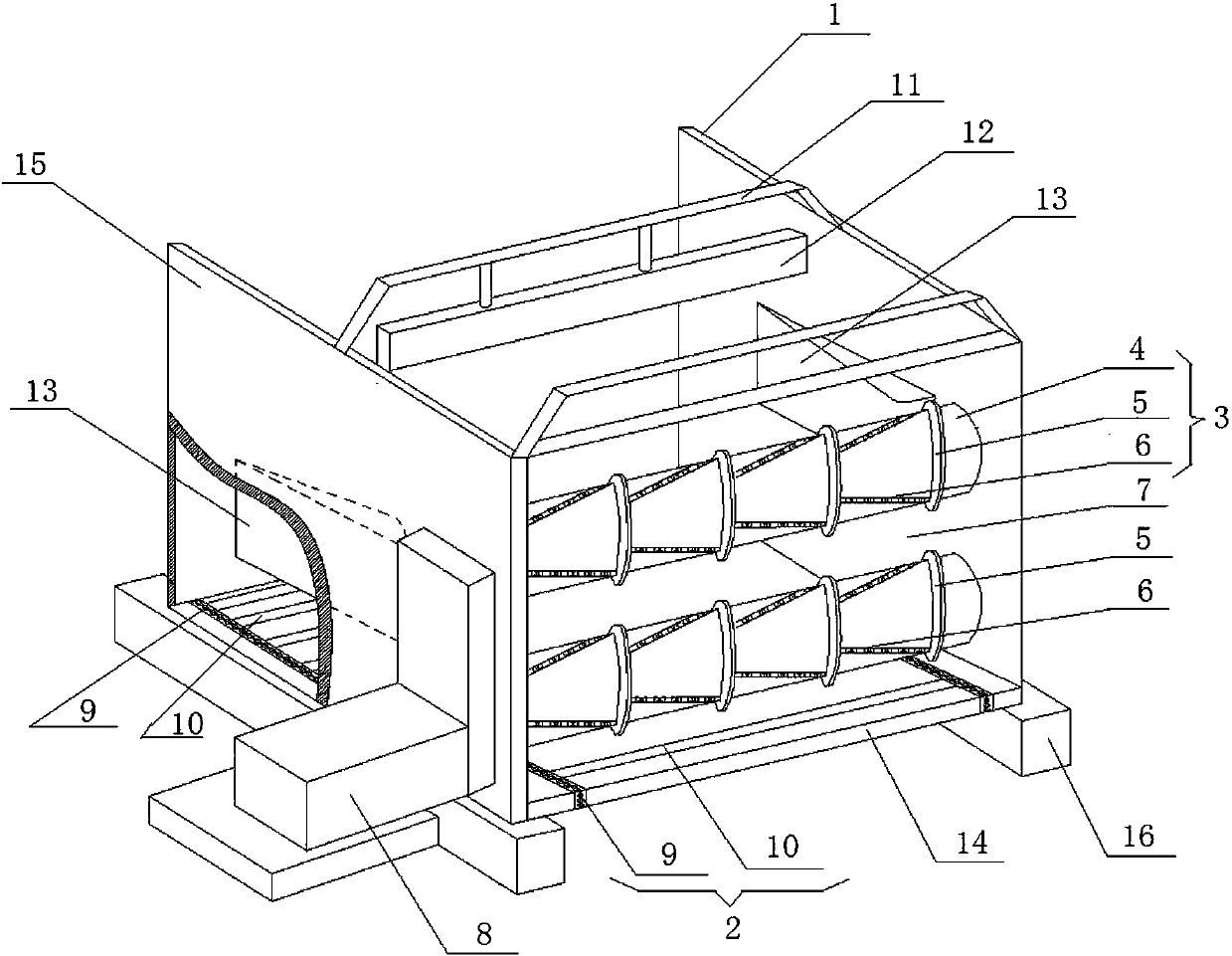

[0023] Such as figure 1 As shown, a heavy-duty bale automatic breaking and feeding device includes a body 1 composed of a bottom plate 14, a side plate 15 and a base 16. One end of the body 1 is provided with a bale propulsion mechanism 2, and the other end of the body is adjacent to the propelling mechanism. The mechanism 2 is provided with a bale-breaking feeding mechanism 3, and the pushing mechanism 2 pushes the bale to the breaking-bale feeding mechanism 3 from one end of the body 1 at a constant speed. Specifically, the propulsion mechanism 2 is a chain-plate conveyor, including chains 9 arranged on both sides of the bottom plate 14 of the body, and a plurality of chain plates 10 are connected in parallel between the chains 9, driven by a motor arranged on one side of the body base 16 8 and the sprocket drive chain operation, ther...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com