Large size liquid crystal panel carrying tool

A technology of liquid crystal panels and handling tools, which is applied in the direction of transportation and packaging, conveyor objects, furnaces, etc., and can solve the problems of not being able to carry various specifications of liquid crystal panels, so as to facilitate disassembly, improve safety, and prevent shaking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

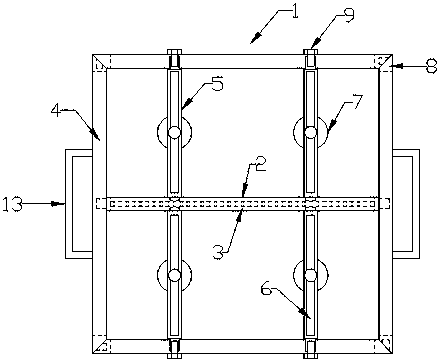

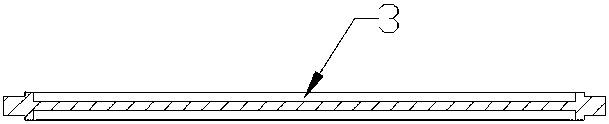

[0029] Such as figure 1 with figure 2 As shown, this embodiment discloses a large-size liquid crystal panel handling tool, including a frame 1, and a cross arm 2 is arranged inside the frame 1, and chute I3 is respectively arranged on both sides of the cross arm 2 and the inner side of the frame 1 and chute II4, a sliding frame bar 5 is provided between the mutually parallel chute I3 and chute II 4, a chute III6 is arranged on the sliding frame bar 5, and a suction cup 7 is installed in the chute III6 .

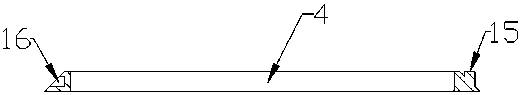

[0030] The frame includes frame bars 8 , and the adjacent frame bars 8 are structurally connected by tenon 14 and tenon groove 15 .

[0031] Such as image 3 As shown, the chute II4 is a through-hole groove, the chute II4 is provided with a locking screw 9, one end of the sliding frame bar 5 is provided with a connecting hole 14, and the connecting hole 14 is provided with an internal thread. The locking screw 9 passes through the chute II4 , and the other end of the loc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com