A three-dimensional nitrogen-sulfur co-doped porous carbon material and its preparation method and application

A nitrogen-sulfur co-doped, porous carbon material technology, applied in carbon preparation/purification, hybrid/electric double-layer capacitor manufacturing, hybrid capacitor electrodes, etc. The reaction steps are cumbersome and other problems, and the effect of good application prospect and industrialization potential, huge application potential and industrial value, and simple preparation process can be achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

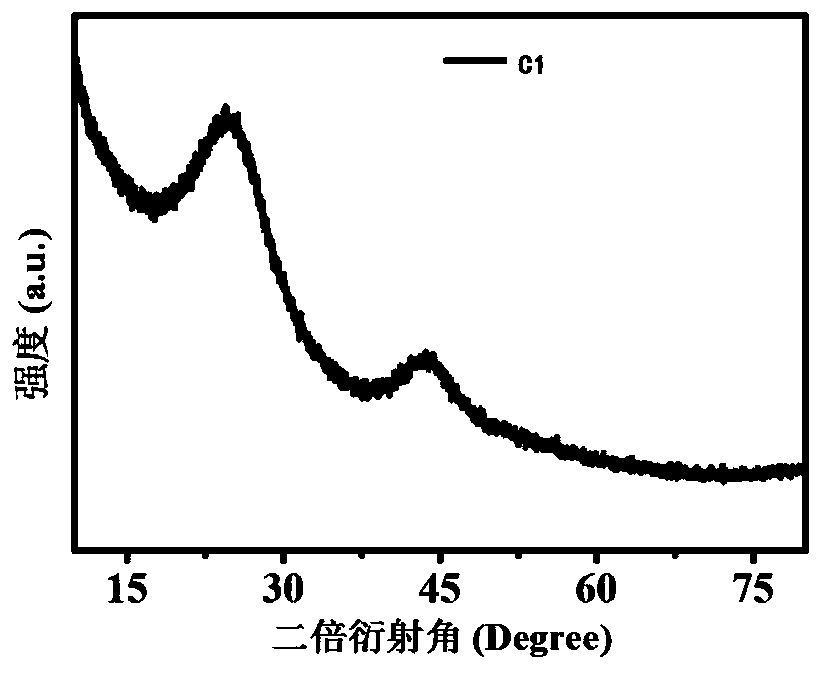

[0039] S1: Put 28ml of pyridine, 2ml of hexachlorobutadiene and 1g of thiocyanuric acid in an autoclave lined with polytetrafluoroethylene for 4 hours at 200°C and 2MPa, in which pyridine and hexachlorobutadiene The mass ratio of olefin to thiocyanuric acid is 24:3:1.

[0040] S2: Relieve the pressure to normal pressure, remove the excess solvent from the reaction, and obtain sample A.

[0041] S3: Mix 1g of the obtained sample with 6g of thiourea;

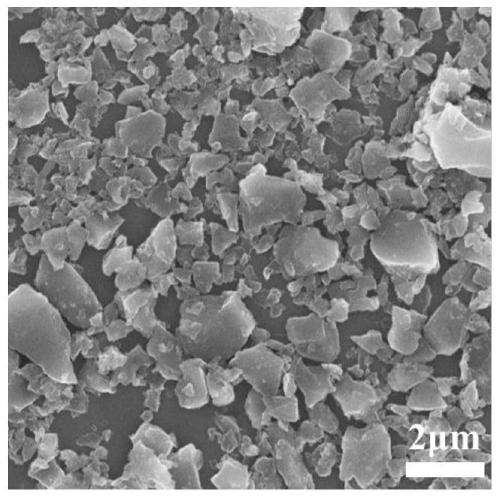

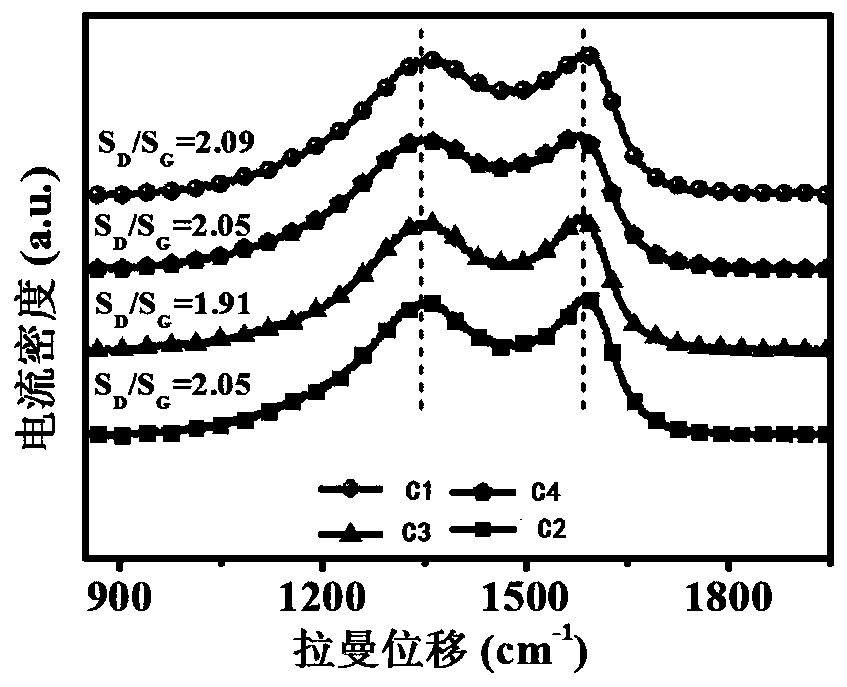

[0042] S4: Put the sample in inert gas N 2 High-temperature treatment at 1000° C. for 2 hours under protection to obtain sample B; S5: ball milling the obtained sample B for 15 minutes to obtain the three-dimensional flake nitrogen-sulfur co-doped porous carbon material. Name it C1.

Embodiment 2-4

[0043] Example 2-4: Investigation of reaction materials in step S1

[0044] Except that thiocyanuric acid was not added in step S1 and step S5 was not performed, the other operations were the same, so that Example 2 was performed in sequence and named C2. Except that step S3 and step S5 are not performed, the other operations are the same, so that embodiment 3 is performed sequentially and named C3. Except that step S5 is not performed, the other operations are the same, so that embodiment 4 is performed sequentially and named C4.

Embodiment 5-8

[0045] Example 5-8: Investigation of the proportion of reaction materials in step S1

[0046] The mass ratios of hexachlorobutadiene and thiocyanuric acid in the raw materials of step S1 were changed to 6:1, 3:1, 3:2, and 1:1, and other operations were unchanged to obtain Example C5- C8.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap