Integrated repairing equipment for road surface engineering

An integrated and equipment technology, applied in road cleaning, road repair, roads, etc., can solve the problems of inconvenient discharge of stagnant water, inconvenient cleaning of debris and gravel, and single function, so as to improve the effect of flood discharge and improve the cleaning effect. Effects, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

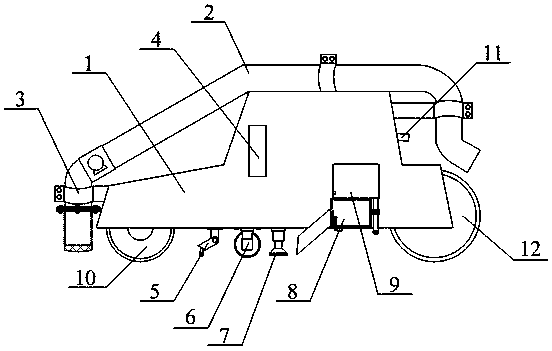

[0040] as attached figure 1 to attach Figure 8 shown

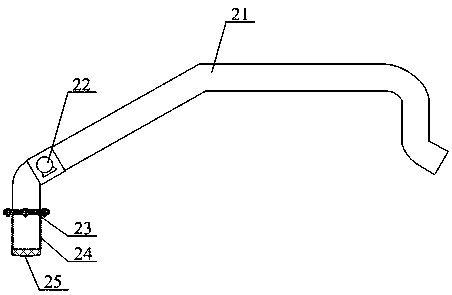

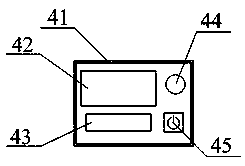

[0041]The present invention provides an integrated refurbishment device for road surface engineering, which includes a device body 1, a flood discharge pipeline structure 2, a fixed snap ring 3, an intelligent control alarm device 4, a road surface level detection device 5, a road surface convex grinding device 6, and gravel Cleaning device 7, gravel collection device 8, sprinkler device 9, front wheel 10, reversing camera 11 and road roller 12, described flood discharge pipeline structure 2 is installed on the upper outside of equipment body 1 by fixing snap ring 3; The above intelligent control alarm device 4 bolts are installed on the inner upper side of the equipment body 1; the road surface level detection device 5, the road surface convex grinding device 6 and the gravel cleaning device 7 are installed on the equipment body 1 by bolts from left to right in turn. The middle and lower left side of the device body 1;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com